Thinner Recycler Machine (20L)

Model: T-20EX

Feed capacity(L): 20

Power(kW): 2

Recovery(%): 95

View More

The T-250Ex suits very large industrial lines, with a 250L capacity and 240-minute treatment time. Perfect for petrochemical, large-scale pharmaceutical, and industrial applications.

Solvent recycling machine heats the solvent, turning it into a gas. The vapor then enters a cooling system where it condenses and flows out as clean organic solvent. This process regenerates and recycles waste and used organic solvents, significantly reducing procurement costs and environmental pollution.

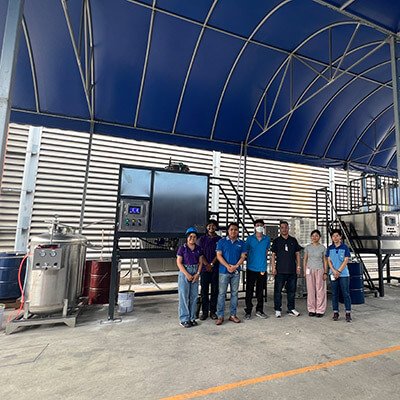

T-250 solvent recycling machine is our hot-selling model. Compared with other recovery machines, this model is more energy-efficient and consumes less power.The efficiency of solvent recovery can reach over 95%.

T-250 solvent recycling machine has an input capacity of 200-250 liters and has a one-button start function, which can achieve fully automatic operation. Automatic feeding and discharging effectively reduces your labor costs.

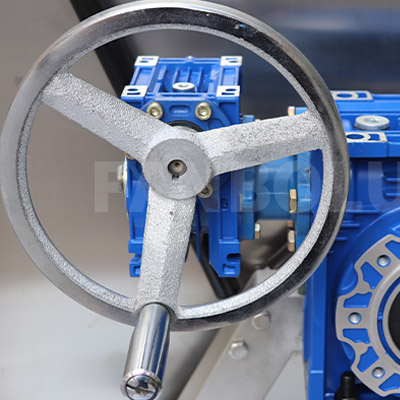

Nitrogen protection, compressed air protection, explosion-proof lamp, observation window, sound and light alarm.

Double pressure control, double stainless steel safety valve, double temperature protection.

Recovery rate: 95% (ratio of recovered solvent to solvent content in waste liquid).

PTFE material, good sealing, solvent resistance and corrosion resistance.

Multi-stage temperature control, steam temperature, recovery time, continuous feeding.

Easy operation, touch screen control. Can be tilted, easy to discharge slag.

Optional vacuum pump for distillation of solvents with boiling point below 300°C.

During production, customers use solvents or water to clean products, generating waste solvents. How should these waste solvents be treated, and which ones can be recycled?

Toluene,Xylene,Benzene

Bromopropane,Dichloromethane,Tetrachloroethylene,Trichloroethylene

Cyclohexane,Cyclohexanone

Various paraffins,Hydrocarbon cleaning agents (D40-D60 solvent oil)

Acetone,Methyl Ethyl Ketone (MEK)

Methanol,Ethanol,Isopropanol (IPA)

Diethyl Ether

Methyl Acetate,Ethyl Acetate,n-Butyl Acetate

Plate cleaning solutions,Car wash solutions,Anti-whitening agents,White spirit,200# solvent oil,Volatile oil,Fin oil,Aviation kerosene,Thinner,Diluent

Cost Saving: In the chemical industry, solvent costs have risen sharply over the past decade due to rising international crude oil prices. Reducing solvent usage or recycling solvents can significantly reduce production costs.

Complying with environmental protection requirements: As environmental regulations become more stringent, waste liquid treatment costs continue to increase. Recycling waste solvents and handing over the residues to environmental companies can help save these costs.

Advanced technology, recycling efficiency can reach 95%.

Automatic feeding, etc., with high degree of automation.

Omron temperature control and pressure control system. High safety.

Various models, dual-system recycling machine, continuous recycling machine, PLC customized recycling machine, etc.

First-class quality, using German technology.

Model | Feed capacity (L) | Power supply (ACV) | Power (kW) | Temperature range (℃) | Treatment time (Min.) | Recovery (%) |

T-20Ex | 20 | 380 | 2 | 5~200 | 120 | 95 |

T-60Ex | 60 | 380 | 4 | 5~200 | 150 | 95 |

T-80Ex | 80 | 380 | 5 | 5~200 | 180 | 95 |

T-90Ex | 90 | 380 | 5 | 5~200 | 180 | 95 |

T-125Ex | 125 | 380 | 6 | 5~200 | 210 | 95 |

T-250Ex | 250 | 380 | 16 | 5~200 | 240 | 95 |

T-600Ex | 600 | 380 | 32 | 5~200 | 270 | 95 |

Model | Feed capacity (L) | Power (kW) | Treatment time (Min.) |

T-20Ex | 20 | 2 | 120 |

T-60Ex | 60 | 4 | 150 |

T-80Ex | 80 | 5 | 180 |

T-90Ex | 90 | 5 | 180 |

T-125Ex | 125 | 6 | 210 |

T-250Ex | 250 | 16 | 240 |

T-600Ex | 600 | 32 | 270 |

Model: T-20EX

Feed capacity(L): 20

Power(kW): 2

Recovery(%): 95

View More

Model: T-80EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Recovery(%): 95

View More