Model: T-20EX

Feed capacity(L): 20

Power(kW): 2

Temperature range (℃): 5~200

Treatment time (Min.): 120

Recovery(%): 95

View More

Perfect for large chemical and pharmaceutical companies, the T-80Ex's 80L capacity and 180-minute treatment time ensure efficient solvent recovery. Ideal for large-scale production.

Solvent recovery machine, efficient and environmentally friendly equipment, is tailor-made for industrial waste solvents. Through advanced distillation technology, waste solvents in production are converted into reusable resources, which not only saves production costs but also reduces environmental pollution. Whether it is dumping, slag discharge or other slag discharge methods, T-80 can respond flexibly to meet the needs of different scenarios. Its price is affordable, but it has the industry's top cost-effectiveness. It is an ideal choice for many companies to achieve solvent recycling, reduce production costs, and practice green production.

As an upgraded product of the third-generation technology, the T-80 solvent recovery machine takes continuous recovery as the core. It not only integrates an efficient distillation system, but also achieves a leap in safety and automation. This model has specially added external safety configuration to ensure operational safety in all aspects; at the same time, the fully automatic feeding system makes operation more convenient, reduces manual intervention, and improves recovery efficiency. This innovative equipment not only reflects the adherence to the concept of environmental protection, but also is an important tool for enterprises to achieve sustainable development and improve economic benefits.

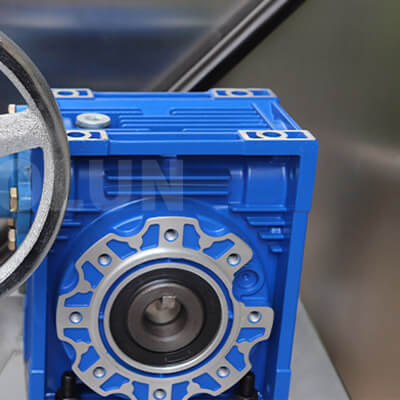

Precision pressure control system: realize accurate control and stable maintenance of pressure during the recovery process to ensure solvent recovery efficiency and safety.

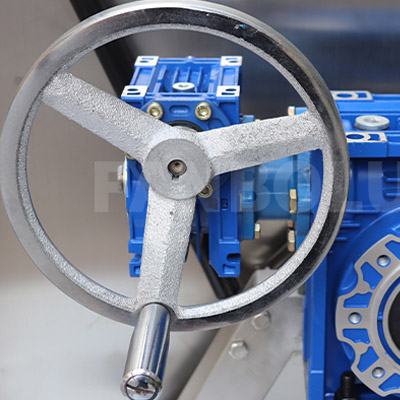

High-efficiency continuous feeding system: automated continuous feeding device to achieve uninterrupted solvent supply, greatly improving recovery efficiency and production continuity.

Large safety valve: form multiple safety protection nets to effectively prevent overpressure.

Intelligent temperature control system: Omron high-precision temperature control module to accurately control the heating temperature.

Window and light function: easy to observe the solvent recovery process and improve the convenience of equipment operation.

During production, customers use solvents or water to clean products, generating waste solvents. How should these waste solvents be treated, and which ones can be recycled?

Ethanol (alcohol): commonly used for cleaning, disinfection and as a solvent.

Methanol: widely used in the fields of chemical industry, medicine, etc.

Toluene: commonly used in the manufacturing process of coatings, inks, resins, etc.

Xylene: used as a solvent and diluent in the coatings, inks, rubber and other industries.

Petroleum ether: a mixture of hydrocarbons extracted from petroleum, used as a solvent and cleaning agent.

Acetone: widely used in chemical laboratories, coatings, adhesives and other fields.

Methyl ethyl ketone (MEK): used as a solvent and diluent in the coatings, inks, cleaning agents and other industries.

Ethyl acetate: commonly used as a solvent for coatings, inks, and adhesives.

Dimethyl carbonate (DMC): as a green solvent, it is used in coatings, pesticides and other fields.

NMP (N-methylpyrrolidone): used as a high-performance solvent in electronics, coatings, adhesives and other fields.

DMF (dimethylformamide): used as a solvent and reaction medium in the pharmaceutical, pesticide, dye and other industries.

The specific types of solvents that can be recovered and the recovery effect need to be determined based on the specific model, configuration and actual use of the T-80 solvent recovery machine.

Type of recovered solvent: clarify the type of solvent to be recovered. Different solvent recovery machines may be optimized for different solvents. Make sure the selected equipment can effectively recover the solvents you need.

Recovery efficiency and processing capacity: determine the required recovery efficiency and processing capacity. Large production lines require equipment with high recovery rates and large processing volumes, while small laboratories may pay more attention to the flexibility and precision of the equipment.

Safety: whether the equipment has explosion-proof design, multiple safety protection mechanisms (such as temperature protection, pressure protection, etc.) and certification in accordance with relevant safety standards (such as CE, UL, etc.).

Convenience of operation: choose equipment that is easy to operate and maintain. Consider whether the control interface of the equipment is intuitive, whether it supports Chinese display, whether it has remote monitoring function, etc.

Energy consumption and cost: equipment with high energy efficiency ratio and good energy saving effect can reduce long-term operating costs.

After-sales service: support in equipment installation and commissioning, technical training, troubleshooting and accessories supply.

Brand and reputation: choose well-known brands and suppliers with good reputation. A more complete product line and a wider user group can provide more reliable products and services.

Model: T-20EX

Feed capacity(L): 20

Power(kW): 2

Temperature range (℃): 5~200

Treatment time (Min.): 120

Recovery(%): 95

View More

Model: T-60EX

Feed capacity(L): 60

Power(kW): 4

Temperature range (℃): 5~200

Treatment time (Min.): 150

Recovery(%): 95

View More

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Temperature range (℃): 5~200

Treatment time (Min.): 180

Recovery(%): 95

View More

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Temperature range (℃): 5~200

Treatment time (Min.): 210

Recovery(%): 95

View More

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Temperature range (℃): 5~200

Treatment time (Min.): 240

Recovery(%): 95

View More

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Temperature range (℃): 5~200

Treatment time (Min.): 270

Recovery(%): 95

View MoreHigh recovery rate: A solvent recovery rate of more than 95% can be achieved.

Fast recovery: A minimum recovery of 30-50 liters of solvent per hour (specific data may vary slightly depending on the model and configuration).

Explosion-proof design: Ensure safe operation in flammable and explosive environments.

Multiple safety protections: sound and light alarm device, pressure control system, and electronic dual temperature control system, etc.

Low energy consumption: The equipment has low power but high recovery efficiency, which realizes the effective use of energy.

Durable and reliable: corrosion-resistant and high-temperature resistant.

Customizable configuration: Provide a variety of optional configurations to meet the personalized needs of different customers.

Technical support: Professional technical team, providing comprehensive technical support and solutions.

Model | Feed capacity (L) | Power supply (ACV) | Power (kW) | Temperature range (℃) | Treatment time (Min.) | Recovery (%) |

T-20Ex | 20 | 380 | 2 | 5~200 | 120 | 95 |

T-60Ex | 60 | 380 | 4 | 5~200 | 150 | 95 |

T-80Ex | 80 | 380 | 5 | 5~200 | 180 | 95 |

T-90Ex | 90 | 380 | 5 | 5~200 | 180 | 95 |

T-125Ex | 125 | 380 | 6 | 5~200 | 210 | 95 |

T-250Ex | 250 | 380 | 16 | 5~200 | 240 | 95 |

T-600Ex | 600 | 380 | 32 | 5~200 | 270 | 95 |

Model | Feed capacity (L) | Power (kW) | Treatment time (Min.) |

T-20Ex | 20 | 2 | 120 |

T-60Ex | 60 | 4 | 150 |

T-80Ex | 80 | 5 | 180 |

T-90Ex | 90 | 5 | 180 |

T-125Ex | 125 | 6 | 210 |

T-250Ex | 250 | 16 | 240 |

T-600Ex | 600 | 32 | 270 |

Model: T-20EX

Feed capacity(L): 20

Power(kW): 2

Recovery(%): 95

View More

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Recovery(%): 95

View More

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Recovery(%): 95

View More