1. Benzene solvents: such as toluene, xylene, benzene, etc. These solvents are widely used in the fields of chemical industry, coatings, paints, etc.

Designed for medium-scale chemical and pharmaceutical industries, the T-60Ex has a 60L capacity and 150-minute treatment time. Suitable for chemical synthesis and industrial cleaning.

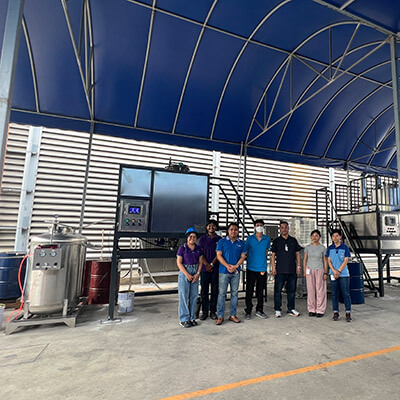

Solvent reclaimer is an environmentally friendly equipment that utilizes the principle of distillation. It heats and evaporates waste organic solvents to a gaseous state, and then liquefies and recovers them through the cooling system to achieve solvent regeneration. It can not only effectively save corporate procurement costs, but also significantly reduce environmental pollution. Suitable for recycling a variety of solvents such as acetone and alcohol. The equipment adopts explosion-proof design to ensure safe operation.

T-60 solvent reclaimer also optimizes distillation efficiency and solvent recovery rate, and realizes an efficient and energy-saving solvent regeneration process through precise process design.

Excellent safety design: The whole machine is designed in accordance with the highest explosion-proof safety standards and has passed the EU CE certification.

Independently developed PID control system: supports multi-program settings, flexibly responds to different solvent recovery needs, and realizes automated production.

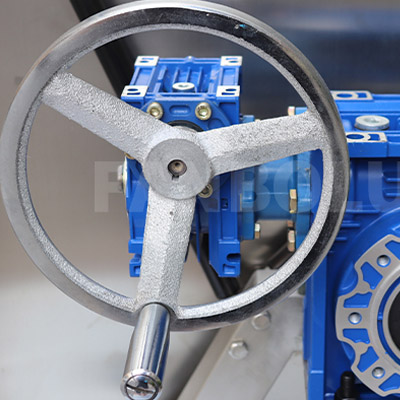

Special explosion-proof operating mechanism: more convenient and safer operation.

High-quality stainless steel chassis: easy to clean and maintain.

Timed shutdown: energy-saving and worry-free.

Triple temperature protection: automatically start the protection program to protect the safety of operation in all directions.

Intelligent alarm system: timely remind operators to pay attention and ensure that Problems Solved by are handled in time.

During production, customers use solvents or water to clean products, generating waste solvents. How should these waste solvents be treated, and which ones can be recycled?

1. Benzene solvents: such as toluene, xylene, benzene, etc. These solvents are widely used in the fields of chemical industry, coatings, paints, etc.

2. Ketone solvents: such as acetone, butanone, cyclohexanone, etc., are often used in cleaning, dissolving and diluting processes.

3. Ester solvents: such as methyl acetate, ethyl acetate, n-butyl acetate, etc., have good solubility and volatility, and are often used in coatings, inks and other industries.

4. Halogenated hydrocarbon solvents: such as dichloromethane, trichloroethylene, tetrachloroethylene, etc. These solvents have important applications in electronics, metal processing and other industries.

5. Alcohol solvents: such as methanol, ethanol, isopropanol, etc., are widely used in chemical industry, medicine, coatings and other fields.

6. Other organic solvents: such as ether, cyclohexane, alkanes, plate washing water, car washing water, anti-white water, white gasoline, 200# solvent oil, volatile oil, fin oil, aviation kerosene, D40-D-60 solvent oil, hydrocarbon cleaning agent, thinner, thinner and other mixed solvents and other organic solvents not listed.

The types of solvents listed above are only some examples, not all. In actual applications, the T-60 solvent reclaimer may also be able to recover other types of organic solvents. Therefore, when choosing to use this equipment, it is recommended to consult and confirm in detail according to the specific solvent type and recovery requirements.

Problems Solved by Solvent Reclaimers

Reduce operating costs: Efficiently recycle waste organic solvents, significantly reduce the purchase demand for solvents, and reduce the production costs of enterprises.

Environmental compliance: Reduce the emission of harmful substances, help enterprises achieve green production, and comply with environmental regulations.

Resource recycling: Convert waste solvents into clean and reusable solvents to achieve resource recycling and reduce waste.

Solvent properties: The volatility, stability and safety of the solvent directly affect the ease and safety of recycling. Highly volatile solvents are easy to recycle, but attention must be paid to their stability and safety to humans and the environment.

Recycling method: The choice of recycling method directly affects recycling efficiency and cost. The distillation method achieves efficient recovery by controlling temperature and pressure; the extraction method relies on the selection of extraction agents and extraction conditions; membrane separation technology provides a new and efficient recovery method.

Operating conditions: Operating conditions such as temperature, pressure and flow rate are key factors in regulating recovery efficiency. Appropriately increasing the temperature, reducing the pressure or optimizing the flow rate can significantly improve the recovery efficiency.

Equipment factors: The performance and maintenance of equipment are crucial to solvent recovery. Efficient, corrosion-resistant equipment ensures a stable and efficient recycling process, while regular equipment maintenance extends equipment life and reduces breakdowns.

Environmental factors: Environmental regulations and energy consumption are environmental factors that cannot be ignored in the solvent recovery process. Enterprises need to comply with relevant environmental protection regulations, reduce pollutant emissions, and optimize energy consumption to improve economic and environmental benefits.

Model | Feed capacity (L) | Power supply (ACV) | Power (kW) | Temperature range (℃) | Treatment time (Min.) | Recovery (%) |

T-20Ex | 20 | 380 | 2 | 5~200 | 120 | 95 |

T-60Ex | 60 | 380 | 4 | 5~200 | 150 | 95 |

T-80Ex | 80 | 380 | 5 | 5~200 | 180 | 95 |

T-90Ex | 90 | 380 | 5 | 5~200 | 180 | 95 |

T-125Ex | 125 | 380 | 6 | 5~200 | 210 | 95 |

T-250Ex | 250 | 380 | 16 | 5~200 | 240 | 95 |

T-600Ex | 600 | 380 | 32 | 5~200 | 270 | 95 |

Model | Feed capacity (L) | Power (kW) | Treatment time (Min.) |

T-20Ex | 20 | 2 | 120 |

T-60Ex | 60 | 4 | 150 |

T-80Ex | 80 | 5 | 180 |

T-90Ex | 90 | 5 | 180 |

T-125Ex | 125 | 6 | 210 |

T-250Ex | 250 | 16 | 240 |

T-600Ex | 600 | 32 | 270 |

Model: T-20EX

Feed capacity(L): 20

Power(kW): 2

Recovery(%): 95

View More

Model: T-80EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Recovery(%): 95

View More

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Recovery(%): 95

View More