Thinner Recycler Machine (20L)

Model: T-20EX

Feed capacity(L): 20

Power(kW): 2

Recovery(%): 95

View More

Tailored for ultra-large industrial production, the T-600Ex handles 600L with a 270-minute treatment time. Ideal for large petrochemical plants and high-volume solvent recovery needs.

Solvent recycling system is a device that uses the principle of distillation to recover solvents. It evaporates the solvent into a gaseous state by heating, and then the steam enters the cooling system to liquefy and flow out, thereby recovering clean organic solvents, which has significant environmental and economic benefits.

T-600 solvent recycling system has a built-in high-efficiency electric vacuum pump system and abandons the traditional vacuum tank design. It not only simplifies the structure, but also improves the convenience and efficiency of operation, becoming our popular star product.

T-600 solvent recycling system is designed for large-scale production and is compatible with a wide capacity range of 550 to 600 liters. It realizes unmanned operation from automatic feeding to discharging, and supports continuous discharge during the work process, greatly improving production continuity and flexibility.

Using cutting-edge heating distillation technology, the T-600 solvent recycling system achieves efficient and stable recovery of waste solvents, with a processing capacity of up to 200 to 300 liters per hour, and a breakthrough solvent recovery efficiency of more than 95%, far exceeding similar products, effectively reducing production costs and improving resource utilization.

Liquid level protection system and compressed air protection device.

Dual pressure control, dual stainless steel safety valves, dual temperature protection, dual outflow liquid temperature protection, dual gas temperature protection, etc.

Feed capacity: 400-450 liters, continuous feeding and continuous discharging.

Can work continuously for 24 hours.

Recovery rate: 95% (ratio of recovered solvent volume to solvent content in waste liquid).

Certified explosion-proof.

Pure PTFE material seal, good sealing, solvent resistance and corrosion resistance.

During production, customers use solvents or water to clean products, generating waste solvents. How should these waste solvents be treated, and which ones can be recycled?

Such as: Toluene, Xylene, Benzene, Methanol, Ethanol, Isopropanol (IPA), Acetone, Methyl Ethyl Ketone (MEK).

Such as: Various paraffins, Hydrocarbon cleaning agents (D40-D60 solvent oil), Bromopropane, Dichloromethane, Tetrachloroethylene, Trichloroethylene, Cyclohexane, White spirit.

Such as: Ethyl Acetate, n-Butyl Acetate, Acetone, Methyl Ethyl Ketone (MEK).

Such as: Plate cleaning solutions, Car wash solutions, Anti-whitening agents, White spirit, Dichloromethane, Tetrachloroethylene, Trichloroethylene, Cyclohexane

Cost saving: Reduce dependence on new solvents. Reduce the cost of purchasing solvents, as well as the transportation, storage and disposal costs of handling waste solvents.

Comply with environmental protection requirements: Solvent recycling systems provide a waste solvent treatment method that meets regulatory requirements. By recycling and reusing waste solvents, the purchase of new solvents and the discharge of waste solvents are reduced, thereby achieving the dual goals of environmental protection and energy saving.

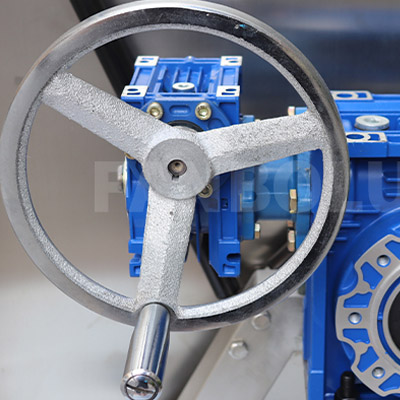

Core safety advantages: comprehensive explosion-proof design, special explosion-proof operating mechanism, improve the convenience and safety of operation in explosion-proof environment.

Intelligent control system: autonomous PID control system, intelligent timed shutdown, ensure safe shutdown of equipment, save energy.

Durable and easy to maintain: stainless steel body, stable and durable, easy to maintain, greatly reducing maintenance costs.

Multiple safety protection: triple temperature protection, alarm system, ensure safe operation.

Model | Feed capacity (L) | Power supply (ACV) | Power (kW) | Temperature range (℃) | Treatment time (Min.) | Recovery (%) |

T-20Ex | 20 | 380 | 2 | 5~200 | 120 | 95 |

T-60Ex | 60 | 380 | 4 | 5~200 | 150 | 95 |

T-80Ex | 80 | 380 | 5 | 5~200 | 180 | 95 |

T-90Ex | 90 | 380 | 5 | 5~200 | 180 | 95 |

T-125Ex | 125 | 380 | 6 | 5~200 | 210 | 95 |

T-250Ex | 250 | 380 | 16 | 5~200 | 240 | 95 |

T-600Ex | 600 | 380 | 32 | 5~200 | 270 | 95 |

Model | Feed capacity (L) | Power (kW) | Treatment time (Min.) |

T-20Ex | 20 | 2 | 120 |

T-60Ex | 60 | 4 | 150 |

T-80Ex | 80 | 5 | 180 |

T-90Ex | 90 | 5 | 180 |

T-125Ex | 125 | 6 | 210 |

T-250Ex | 250 | 16 | 240 |

T-600Ex | 600 | 32 | 270 |

Model: T-20EX

Feed capacity(L): 20

Power(kW): 2

Recovery(%): 95

View More

Model: T-80EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Recovery(%): 95

View More