Solvent Reclaimer (60L)

Model: T-60EX

Feed capacity(L): 60

Power(kW): 4

Recovery(%): 95

View More

Ideal for small labs and pharmaceutical production, the T-20Ex efficiently recovers solvents with a 20L capacity and 120-minute treatment time. Perfect for chemical research and small-scale manufacturing.

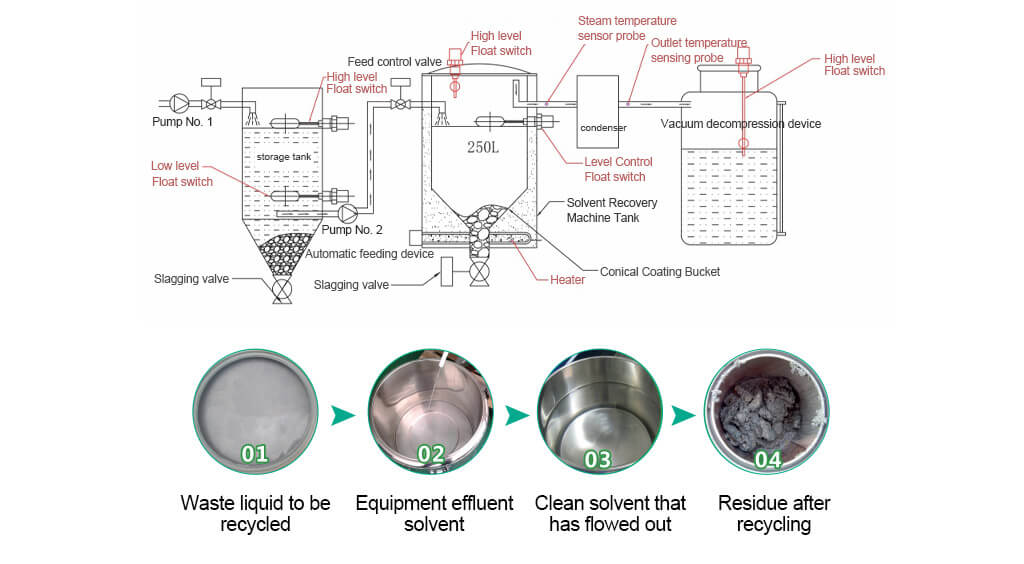

Thinner recycler machine is an environmentally friendly equipment that efficiently processes waste organic solvents. It uses advanced distillation technology to convert waste solvents into reusable clean solvents, reducing production costs and significantly reducing environmental pollution.

T-20 thinner recycler machine adopts a fully explosion-proof structure and strictly follows safety standards. It can be used safely in corrosive environments or flammable and explosive places. At the same time, it has obtained CE EU certification, with excellent quality and trustworthiness, demonstrating its high international standards.

As a leader in air-cooling technology, T-20 thinner recycler machine is designed for high efficiency and energy saving. Its single feed capacity is 20 liters, and it is equipped with a powerful and energy-saving motor of only 2KW, achieving high recovery efficiency with low energy consumption. Using advanced PID programming control technology, T-20 can accurately control the recovery process to ensure the purity and efficiency of solvent recovery.

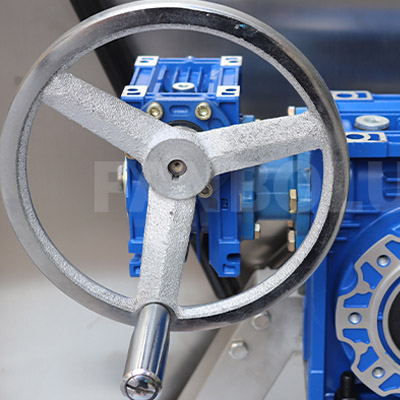

Core safety advantages: comprehensive explosion-proof design, special explosion-proof operating mechanism, improve the convenience and safety of operation in explosion-proof environment.

Intelligent control system: autonomous PID control system, intelligent timed shutdown, ensure safe shutdown of equipment, save energy.

Durable and easy to maintain: stainless steel body, stable and durable, easy to maintain, greatly reducing maintenance costs.

Multiple safety protection: triple temperature protection, alarm system, ensure safe operation.

Insert the waste liquid pipe on the feed pump into the waste barrel to ensure that the waste liquid can enter the recovery machine smoothly.

Connect the power supply, gas source and water source, and turn on the power switch.

Click "Start" on the control screen, and the feed pump starts working until it reaches the highest liquid level and stops automatically.

Enter the menu and select "Parameter setting", set the heating temperature according to the boiling point of ethanol (about 78°C), usually set to 120-130°C (40-50°C higher than the boiling point).

Set the working time, such as working for 600 minutes a day, which can be divided into two sections: the first section is heated at 100°C for 420 minutes, and the second section is heated at 120-130°C for 180 minutes.

The machine automatically starts feeding and stops after reaching the set liquid level.

The heating system starts and heats in stages according to the preset temperature. First, remove low-boiling impurities at a lower temperature (if possible).

Then, raise the temperature to above the boiling point of ethanol (such as 120-130°C) to evaporate the ethanol quickly.

For continuous feeding models, the machine continues to feed and completes most of the evaporation within the set 420 minutes.

Starting from the 421st minute, stop feeding and use the remaining 180 minutes to complete the evaporation of the remaining ethanol in the pot.

Set the shutdown temperature to 10°C lower than the boiling point of ethanol (about 68°C). When running under vacuum, it needs to be adjusted according to the evaporation temperature.

When the shutdown temperature is reached, the machine automatically stops heating and prepares to shut down.

During the entire recycling process, you must strictly follow the safety operating procedures and wear protective equipment, such as safety helmets, protective glasses, protective clothing, etc.

For flammable and explosive solvents, additional explosion-proof measures must be taken to ensure the safety of the operating environment.

Regularly maintain the thinner recycler machine, check the integrity of components such as pipes, valves, and heating systems, and replace damaged parts in a timely manner.

Reduce waste treatment and storage costs: Recycling through thinner recycler machines reduces the amount of waste solvents that need to be stored and processed, thereby reducing related costs.

Enhance corporate image and brand value: Actively taking environmental protection measures and energy-saving and consumption-reducing measures can win the recognition of customers and the market, and help enhance corporate image and brand value.

Improve production efficiency and product quality: Using recycled solvents to continue production reduces the frequency of solvent replacement and downtime, thereby improving production efficiency.

Model | Feed capacity (L) | Power supply (ACV) | Power (kW) | Temperature range (℃) | Treatment time (Min.) | Recovery (%) |

T-20Ex | 20 | 380 | 2 | 5~200 | 120 | 95 |

T-60Ex | 60 | 380 | 4 | 5~200 | 150 | 95 |

T-80Ex | 80 | 380 | 5 | 5~200 | 180 | 95 |

T-90Ex | 90 | 380 | 5 | 5~200 | 180 | 95 |

T-125Ex | 125 | 380 | 6 | 5~200 | 210 | 95 |

T-250Ex | 250 | 380 | 16 | 5~200 | 240 | 95 |

T-600Ex | 600 | 380 | 32 | 5~200 | 270 | 95 |

Model | Feed capacity (L) | Power (kW) | Treatment time (Min.) |

T-20Ex | 20 | 2 | 120 |

T-60Ex | 60 | 4 | 150 |

T-80Ex | 80 | 5 | 180 |

T-90Ex | 90 | 5 | 180 |

T-125Ex | 125 | 6 | 210 |

T-250Ex | 250 | 16 | 240 |

T-600Ex | 600 | 32 | 270 |

Model: T-80EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Recovery(%): 95

View More

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Recovery(%): 95

View More