Solvent Recycling Acetone

A Complete Guide to Cost Savings & Sustainability

Acetone is one of the most widely used solvents in industries ranging from manufacturing and automotive to pharmaceuticals and cosmetics. However, frequent disposal of used acetone is not only costly but also harmful to the environment. This is where solvent recycling acetone comes in — a process that allows businesses to reclaim and reuse acetone, saving money and reducing waste.

Turns harmful waste into reusable resources

What is Solvent Recycling?

Solvent recycling is the process of cleaning and purifying used solvents so they can be reused. For acetone, this typically involves distillation — heating the solvent until it vaporizes and then condensing it back into liquid form, leaving behind contaminants.

According to the U.S. Environmental Protection Agency (EPA), recycling solvents can reduce hazardous waste by up to 90%.

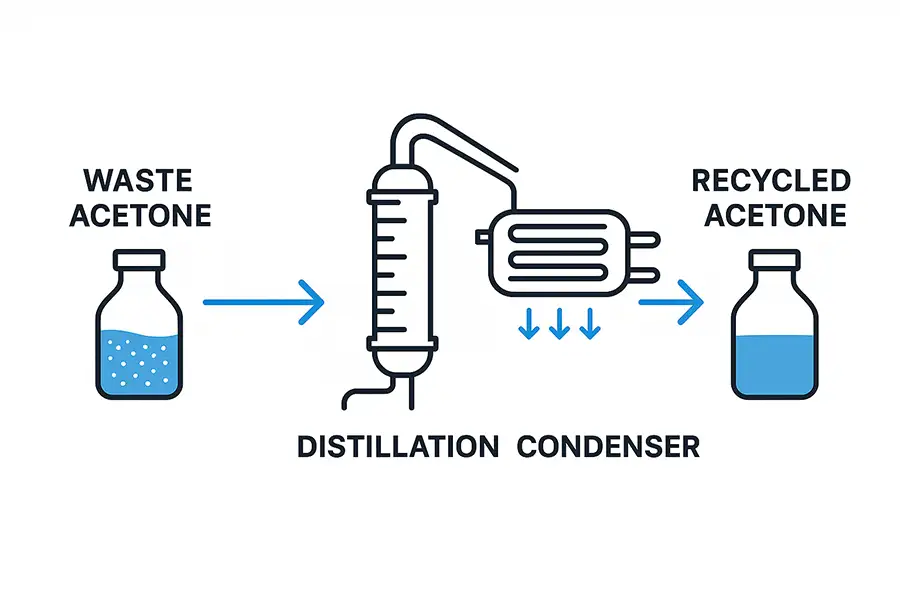

How Does Acetone Recycling Work?

The most common method for acetone recycling is distillation using a solvent recycling system. Here's the step-by-step process:

Collection

Used acetone is collected in a storage container for processing.

Heating

The solvent recycler heats the acetone until it vaporizes.

Condensation

The vapor is cooled back into high-purity liquid form.

Separation

Contaminants remain in the boiling chamber while clean acetone is collected.

Modern machines, like the solvent recycler machine, are designed to be easy to operate, energy-efficient, and capable of handling various solvent types beyond acetone.

Benefits of Recycling Acetone

- Cost Savings: Reduce purchase costs by 50-80%

- Environmental Impact: Lower hazardous waste generation

- Regulatory Compliance: Meet EPA and local regulations

- Operational Efficiency: Continuous clean solvent supply

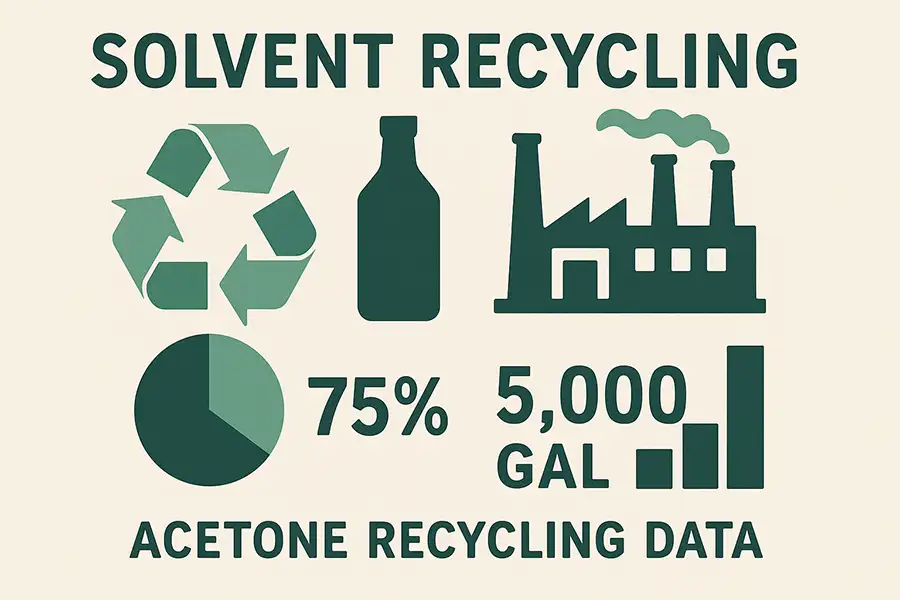

Industry Data and Trends

The solvent recycling market is rapidly growing under pressure from both environmental regulations and cost saving pressures:

Industry Growth

Global solvent recycling expected to grow at 5.8% CAGR from 2023-2028.

Waste Reduction

Adopting sustainable tech including solvent recycling could reduce operational waste by 40% by 2030.

Regulatory Influence

Over 85% of industrial businesses are adapting to stricter EPA regulations.

Comparison: New Acetone vs. Recycling

| Factor | Buying New Acetone | Recycling Acetone |

|---|---|---|

| Cost per Gallon | $15–$25 | $3–$5 |

| Annual Cost (1500 gal) | $30,000–$37,500 | $4,500–$7,500 |

| Environmental Impact | High waste generation | Low waste generation |

| Material Sustainability | Limited resources used | Closed-loop solution |

| Regulatory Compliance | More requirements | Simplified compliance |

| ROI Timeline | Not applicable | 6-12 months |

Compare Costs for Your Business

Choosing the Right Recycling Equipment

When selecting a solvent recycler, consider capacity, energy efficiency, ease of operation, and compatibility with multiple solvents:

Basic Recycler

Capacity: 5-20 gallons

Suitable for small labs

Single-solvent processing

Simple operation

Advanced Systems

Capacity: 20-100 gallons

Manufacturing facilities

Multi-solvent compatibility

Automated controls

Energy recovery systems

Conclusion: The Future is Recycling

Solvent recycling acetone is essential for any business using acetone regularly. By investing in solvent recycling equipment, companies can achieve significant cost savings, support sustainability goals, and ensure regulatory compliance. In a circular economy, recycling isn't just smart — it's essential.