Solvent Distillation Recycling: A Complete Guide to Sustainable Solvent Recovery

In modern manufacturing and laboratory environments, solvents play a vital role in cleaning, dissolving, and processing materials. However, once used, these solvents often become contaminated and are typically discarded, creating significant solvent waste problems. This leads to high disposal costs and environmental burdens. Solvent distillation recycling offers a smart, sustainable solution — recovering and purifying used solvents for reuse. This article will break down how solvent recycling works, why it matters, and how solvent distillation technology is shaping the future of sustainable industry.

What Is Solvent Distillation Recycling?

Solvent distillation recycling is a process that separates impurities from used solvents through controlled heating and condensation. The principle is simple: different substances have different boiling points. By heating the contaminated solvent, the pure solvent vaporizes first, leaving behind residues. The vapor is then condensed back into liquid form — clean and ready for reuse.

According to a study by the U.S. Environmental Protection Agency (EPA), solvent recovery can reduce hazardous waste generation by up to 80% in industrial settings. This not only minimizes environmental impact but also significantly lowers the cost of purchasing new solvents.

How Does a Solvent Recycler Machine Work?

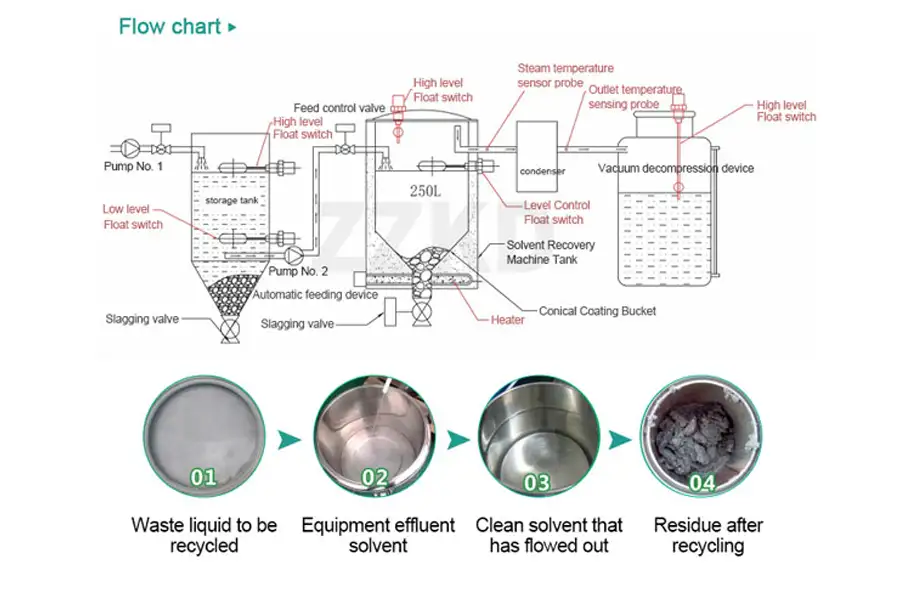

A solvent recycler machine automates this distillation process. It heats used solvent in a sealed chamber, separates contaminants, and collects purified solvent in a clean container. Modern machines are equipped with temperature control, vacuum systems, and safety sensors to ensure efficient and safe operation. Understanding the solvent recovery process is key to maximizing efficiency.

For example, an acetone recycling machine can recover over 95% of used acetone, maintaining its purity for industrial reuse. This efficiency makes solvent recyclers a cost-effective investment for paint manufacturers, automotive workshops, and laboratories.

Interactive Question:

Why not simply dispose of used solvents instead of recycling them?

Disposing of solvents is not only expensive but also environmentally harmful. Many solvents are classified as hazardous waste and require special handling, making proper solvent waste disposal crucial. Recycling allows industries to reuse valuable materials while reducing waste disposal fees and minimizing pollution risks.

Environmental and Economic Benefits

The benefits of solvent distillation recycling extend far beyond cost savings. By reusing solvents, industries reduce their carbon footprint and conserve resources. According to a 2023 report by the European Chemical Agency, solvent recycling can cut CO₂ emissions by up to 60% compared to producing new solvents.

Economically, solvent recovery systems can pay for themselves within one to two years. The reduction in solvent purchase and waste disposal costs quickly offsets the initial investment. Additionally, companies gain compliance advantages under environmental regulations such as ISO 14001 and REACH.

Environmental

Reduces landfill waste, lowers greenhouse gas emissions, and conserves resources

Cost Savings

Reduces expenses for new solvents and hazardous waste disposal

Regulatory Compliance

Meets environmental regulations and reduces liability

Sustainability

Promotes circular economy and corporate social responsibility

Applications of Solvent Distillation Recycling

Solvent recycling is widely used across various industries:

| Industry | Solvents Used | Recycling Benefit |

|---|---|---|

| Paint & coating production | Aketones, Acetate, Xylene | Reduces VOC emissions and material costs |

| Pharmaceutical manufacturing | Ethanol, Methanol, IPA | Ensures solvent purity for critical processes |

| Chemical processing | Solvent mixtures, Toluene | Improves yield and reduces waste costs |

| Automotive maintenance | Degreasers, Paint thinner | Reduces hazardous waste generation |

| Laboratories and research | Specialized solvents | Meets disposal regulations and reduces costs |

Each industry benefits differently, but the principle remains the same: recover, purify, and reuse. For example, paint thinner recovery reduces hazardous waste and improves workplace safety. Learn more about paint thinner disposal and recycling best practices.

Interactive Question:

How pure can recycled solvents be?

With advanced distillation technology, recycled solvents can reach purity levels of 98-99%. This makes them suitable for most industrial applications, often matching the performance of virgin solvents. The key is proper equipment calibration and maintenance.

Choosing the Right Solvent Recovery System

When selecting a solvent recovery system, consider factors like solvent type, volume, and contamination level. Systems such as solvent recovery units are designed to handle different solvent categories — from alcohols and ketones to hydrocarbons.

Modern systems use vacuum distillation to lower boiling points, reducing energy consumption and improving efficiency. Some advanced models also integrate automated cleaning and safety shutdown features.

Challenges and Solutions

While solvent distillation recycling offers many advantages, it also comes with challenges. The most common include managing residual waste, maintaining equipment, and ensuring consistent purity. Proper solvent waste management and regular system maintenance can overcome most issues.

Furthermore, integrating solvent recycling into existing workflows may require staff training. However, most modern systems are designed for user-friendly operation, minimizing technical barriers.

Interactive Question:

Is solvent recycling safe?

Yes. Modern solvent recycling machines include multiple safety features such as explosion-proof designs, temperature sensors, and automatic shutdown systems. When operated according to manufacturer guidelines, they are extremely safe and reliable.

Future of Solvent Distillation Recycling

As sustainability becomes a global priority, solvent distillation recycling is expected to play a crucial role in green manufacturing. Advances in sensor technology, automation, and AI-based process optimization are making recycling systems more efficient and accessible. Learn about emerging technologies in this field.

According to a 2024 industry analysis by the International Chemical Engineering Society, global adoption of solvent recycling systems is projected to increase by 45% by 2030. This trend reflects the growing emphasis on circular economy practices and resource efficiency.

Conclusion

Solvent distillation recycling is more than a technical process — it's a commitment to sustainability, cost efficiency, and environmental responsibility. By investing in modern solvent recycler machines and recovery systems, industries can reduce waste, save money, and contribute to a cleaner future.

To explore detailed guides and equipment options, visit:

By embracing solvent distillation recycling today, industries take an important step toward a sustainable tomorrow.