In the realm of industrial processes, particularly within the chemical, pharmaceutical, and food industries, solvent recovery is a critical operation that cannot be overlooked. But what exactly is solvent recovery, and why is it so vital to these industries?

Understanding Solvents and Their Role

Solvents are substances, usually liquids, that dissolve a solute, resulting in a solution. They play an essential role in various industries, from pharmaceuticals, where they are used to dissolve and extract active ingredients, to the paint industry, where they are used to adjust viscosity and ensure even application. Solvents are also integral in processes such as extraction, purification, and synthesis.

However, the widespread use of solvents brings with it a significant challenge—what to do with the used solvents after they have served their purpose? Disposing of them can be expensive, environmentally harmful, and, in many cases, legally regulated. This is where solvent recovery comes into play.

What is Solvent Recovery?

Solvent recovery is the process of reclaiming solvents from waste materials or exhaust gases during production. Rather than discarding these used solvents, they are captured, purified, and reused in the same or a different process. This not only reduces the environmental impact of solvent use but also leads to significant cost savings for businesses.

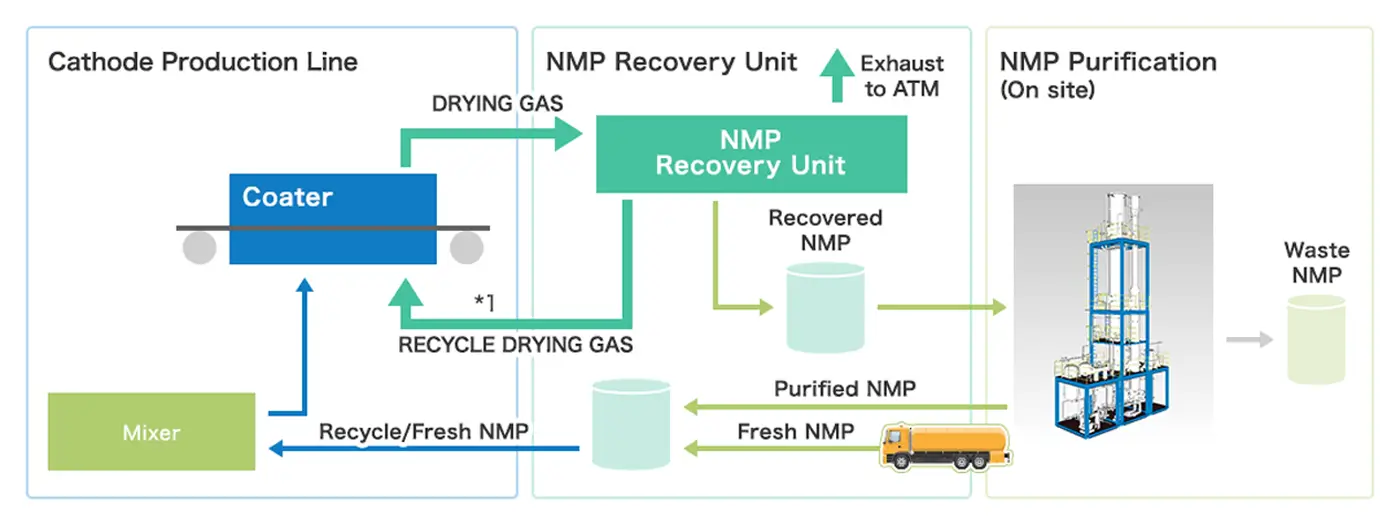

Solvent Recovery Diagram(NMP)

The Mechanism of Solvent Recovery

At its core, solvent recovery involves the separation of solvents from other substances, such as impurities or different solvents, through various methods. The most common techniques include distillation, condensation, adsorption, and membrane separation.

Distillation: This is the most widely used method for solvent recovery. It involves heating the solvent mixture until the more volatile component vaporizes. The vapor is then condensed back into a liquid form, now purified and ready for reuse. Distillation is particularly effective when the solvent and impurities have significantly different boiling points.

Condensation: In this method, solvent vapors are cooled and condensed back into a liquid. This process is often used in combination with distillation and is particularly effective in recovering solvents from gaseous emissions.

Adsorption: This involves passing the solvent-laden gas or liquid over a solid material that selectively adsorbs the solvent. The solvent can then be desorbed from the material and collected for reuse.

Membrane Separation: This method uses a selective membrane to separate the solvent from other components based on their size or chemical properties. While more energy-efficient, membrane separation is often used for specific applications where other methods are less effective.

Why is Solvent Recovery Important?

“One might ask, "Why invest in solvent recovery equipment and processes?" The answer is multifaceted, encompassing economic, environmental, and regulatory considerations.”

1. Economic Benefits

The reuse of solvents can lead to substantial cost savings. Solvents are often expensive, and their disposal can incur additional costs, especially when considering the need to comply with environmental regulations. By recovering and reusing solvents, businesses can reduce their raw material costs and lower their overall production expenses.

For example, a pharmaceutical company that recovers its solvents can significantly cut down on the purchase of fresh solvents. Over time, this leads to a noticeable reduction in operating costs, improving the company’s bottom line.

2. Environmental Impact

In an age where sustainability is more than just a buzzword, solvent recovery is a practical step toward reducing a company's environmental footprint. The recovery process minimizes the amount of waste solvent that needs to be disposed of, thereby reducing the risk of soil and water contamination. Additionally, by reusing solvents, the demand for producing new solvents decreases, conserving resources and reducing greenhouse gas emissions associated with their production and transportation.

3. Regulatory Compliance

Regulatory bodies around the world are increasingly stringent about the disposal of hazardous waste, including solvents. Non-compliance with these regulations can lead to hefty fines, legal action, and damage to a company's reputation. Implementing a solvent recovery system helps companies stay within the legal limits, avoid penalties, and operate in a more environmentally responsible manner.

Introducing Solvent Recovery Machines

“Now that the importance of solvent recovery is clear, the next question is: How is it implemented? The answer lies in solvent recovery machines. These machines are designed to efficiently recover solvents from waste streams, allowing businesses to maximize their resource utilization.”

What Does a Solvent Recovery Machine Do?

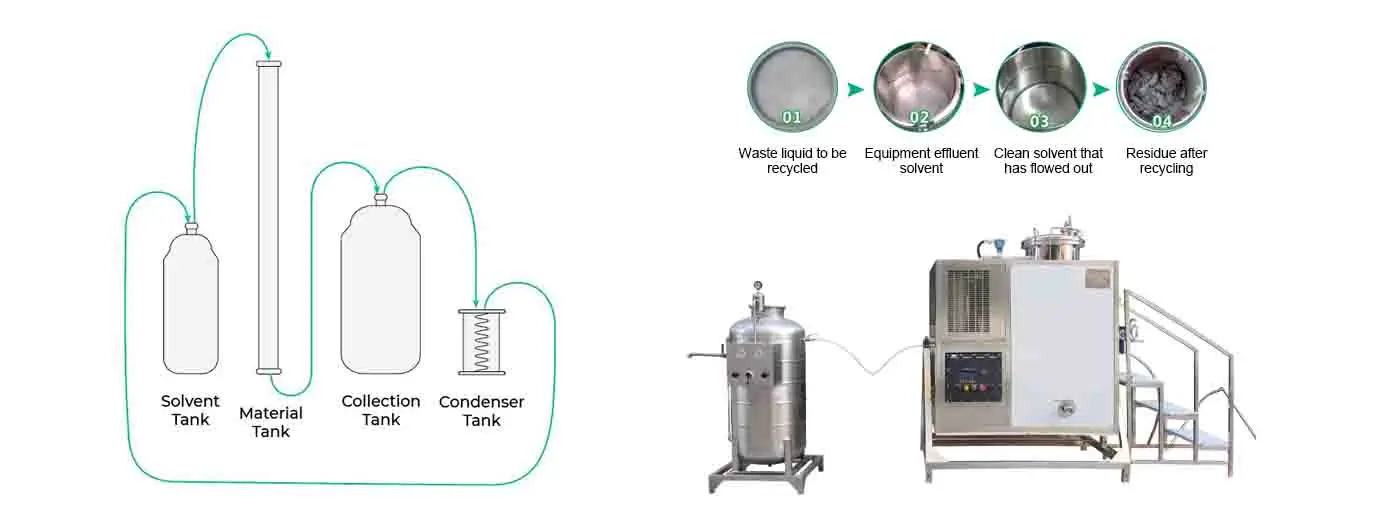

A solvent recovery machine automates the process of capturing, purifying, and reusing solvents. It typically consists of a heating system, a condenser, and a collection system. The waste solvent is introduced into the machine, where it is heated to vaporize the solvent. The vapor then passes through a condenser, where it is cooled and returned to its liquid state, free from impurities.

These machines can handle various types of solvents and are adaptable to different industrial needs. They can be integrated into existing production lines or used as standalone units, depending on the specific requirements of the business.

The specific types of solvents that can be recovered and the recovery effect need to be determined based on the specific model, configuration and actual use of the T-80 solvent recovery machine.

Key Features of Solvent Recovery Machines

Efficiency: Modern solvent recovery machines are designed to maximize efficiency, with high recovery rates and low energy consumption. This ensures that the process is both cost-effective and environmentally friendly.

Safety: Safety is a critical consideration in solvent recovery. These machines are equipped with advanced safety features, including explosion-proof designs, temperature controls, and automated shutdown systems to prevent accidents.

Customization: No two industries are the same, and solvent recovery machines can be customized to meet specific operational needs. Whether dealing with a single type of solvent or multiple solvents, these machines can be tailored to handle the specific requirements of the process.

User-Friendly Interface: Many solvent recovery machines come with intuitive control systems that allow operators to monitor and adjust the process easily. This reduces the need for specialized training and ensures that the recovery process runs smoothly.

Choosing the Right Solvent Recovery Machine

When selecting a solvent recovery machine, several factors must be considered. The type of solvent being recovered, the volume of waste generated, and the specific needs of the production process all play a role in determining the best machine for the job.

Type of Solvent: Some solvents are easier to recover than others, depending on their volatility and chemical properties. It's essential to choose a machine that can handle the specific solvents used in your operation.

Volume of Waste: The capacity of the solvent recovery machine should match the volume of waste generated. A machine that is too small may not be able to handle the load, while one that is too large could be unnecessarily expensive.

Integration with Existing Processes: Consider how the solvent recovery machine will fit into your existing production line. Will it require significant modifications, or can it be easily integrated? How will it impact the overall workflow?

Solvent Recycling Equipment (90L)

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Solvent Recycler Machine (125L)

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Solvent Recycling Machine (250L)

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Recovery(%): 95

View More

Solvent Recycling System (600L)

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Recovery(%): 95

View More

How Often Should Solvent Recovery Machines Be Maintained?

A well-maintained solvent recovery machine is essential for optimal performance and safety. Regular maintenance checks, including cleaning the condenser, inspecting seals and gaskets, and checking for any signs of wear and tear, should be conducted as per the manufacturer's guidelines. Ensuring that the machine is in good working condition not only prolongs its lifespan but also guarantees that it operates efficiently, maximizing solvent recovery and minimizing downtime.

Conclusion: A Wise Investment

Solvent recovery is more than just an environmental initiative; it’s a smart business strategy. By investing in solvent recovery machines, companies can significantly reduce their operational costs, meet regulatory requirements, and contribute to environmental sustainability.

“One might wonder, "Isn't it simpler just to dispose of used solvents?" While it might seem straightforward, the long-term benefits of solvent recovery far outweigh the initial investment. The return on investment from cost savings, environmental compliance, and improved sustainability makes solvent recovery machines a valuable asset for any industry reliant on solvents.”

In a world where resources are finite, and the push for greener practices is growing stronger, solvent recovery represents a forward-thinking approach to industrial operations. Investing in this technology today not only enhances profitability but also positions companies as leaders in sustainable manufacturing practices.