The Safe & Smart Way to Handle Solvents

Stop pouring money down the drain! Discover how solvent recyclers are revolutionizing waste management in labs and industries

Every day, laboratories and industries worldwide face the same dilemma: what to do with used solvents. From isopropyl alcohol to paint thinner and acetone, these chemicals are essential but potentially hazardous when improperly discarded.

The reality is shocking. Pouring solvents down drains contaminates water supplies, harms ecosystems, and violates environmental regulations. The EPA reports that improper solvent disposal contributes to 35% of industrial water pollution incidents annually. But there's a smarter solution that's both eco-friendly and economically brilliant.

The Hidden Dangers of Traditional Disposal Methods

Common disposal methods create serious problems:

Environmental Damage: Solvents contaminate groundwater and harm aquatic life

Legal Risks: Fines up to $50,000 per violation for improper disposal

Health Hazards: Toxic fumes and chemical exposure for workers

Wasted Resources: Buying new solvents when used ones could be purified

According to MIT research, facilities using solvent recyclers reduce their hazardous waste output by 90% while cutting chemical costs by 70-95% annually. That's not just eco-friendly—it's financially transformative!

The Game-Changing Solution: Solvent Recycling Machines

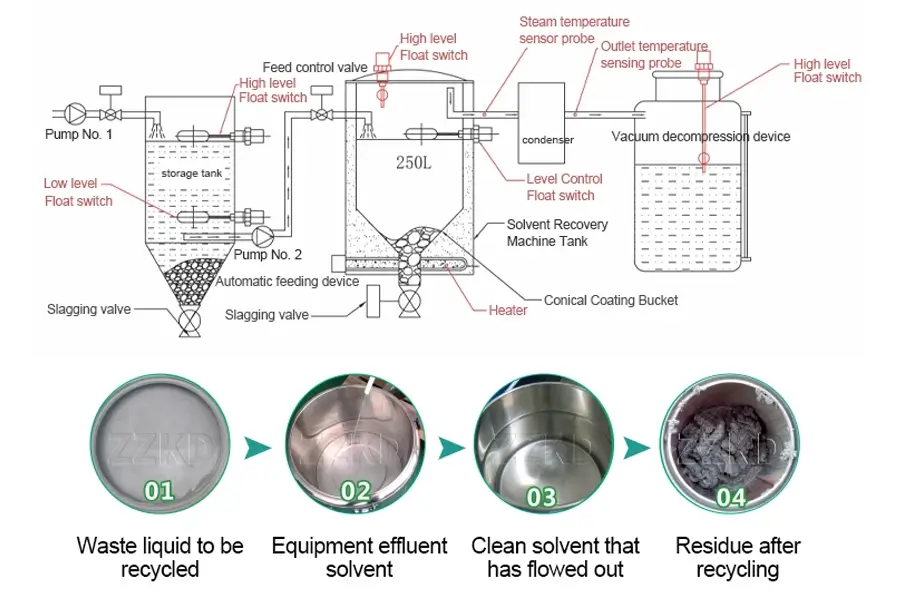

Solvent recyclers are the unsung heroes of modern laboratories and workshops. These ingenious machines distill used solvents, removing contaminants and restoring them to near-original purity. The process is simple:

Collection

Used solvents are gathered in specialized containers

Distillation

Heat separates solvents from contaminants through evaporation

Recovery

Purified solvent condenses and is collected for reuse

Many operations simply aren't aware of the dramatic cost savings and environmental benefits. Others assume the equipment is prohibitively expensive. But consider this: most solvent recyclers pay for themselves in 6-18 months through reduced chemical purchases and waste disposal costs. That's an ROI that's hard to ignore!

For specific solvent disposal guides, check our resources on disposing of isopropyl alcohol and paint thinner disposal methods.

Why Your Bottom Line Will Thank You

Reduction in solvent purchasing costs

Decrease in hazardous waste disposal

Typical payback period for equipment

Beyond the impressive numbers, solvent recyclers deliver tangible benefits:

Environmental Leadership

Dramatically reduce your facility's ecological footprint and enhance your green credentials

Regulatory Compliance

Stay ahead of increasingly strict environmental regulations with documented recycling

Operational Efficiency

Never run out of essential solvents—recycle what you need on demand

Safety Enhancement

Reduce handling risks and storage requirements for hazardous waste

The answer might surprise you. Most operations save thousands annually—some even six figures. Calculate your potential savings with our solvent recycling machine ROI calculator.

Simple Science, Powerful Results

Solvent recyclers operate on distillation principles that have been refined over decades:

The magic happens through precise temperature control. Different solvents boil at specific temperatures, allowing the machine to:

Evaporate the target solvent from contaminants

Capture the vapor in a condensation system

Return purified solvent to a clean collection tank

Modern systems like our advanced solvent recovery units feature automated controls, safety sensors, and energy-efficient designs that make recycling simpler than ever.

Stop Pouring Money Down the Drain!

Join thousands of labs and facilities that have transformed their solvent management

Discover Your Savings TodayFinding Your Perfect Recycling Solution

Not all solvent recyclers are created equal. Consider these factors when choosing:

Volume Requirements

Match machine capacity to your monthly solvent usage—from 5-gallon benchtop units to 50-gallon industrial systems

Solvent Types

Ensure compatibility with your specific solvents—acetone, IPA, ethanol, etc.

Energy Efficiency

Look for modern insulation and recovery systems that minimize power consumption

Safety Features

Automatic shut-off, pressure relief valves, and explosion-proof designs are essential

Pro Tip

Start with a rental program to test different systems before committing to a purchase. Many providers offer flexible options that let you experience the benefits with minimal upfront investment.