Paint Solvent Recovery System: Essential Guide for Sustainable Operations

Transform your solvent waste management with specialized systems that recover up to 95% of paint thinners and solvents. Learn how these systems work, the savings they create, and how to select the optimal solution for your facility.

1 What Is a Paint Solvent Recovery System?

A paint solvent recovery system professionally cleans used paint solvents (like paint thinner, acetone, or xylene) so they can be reused instead of being discarded as hazardous waste. This technology is essential for any facility producing significant solvent waste.

In automotive body shops, furniture factories, coating operations, and printing facilities, solvents are extensively used daily to cleanse spray guns, pipelines, tanks, and mixers. The dirty mixture of solvent and paint residues typically ends up in hazardous waste drums - incurring substantial disposal costs.

According to the European Environment Agency, solvent usage in industry contributes to approximately 8–10% of total VOC emissions in the EU. Reducing solvent consumption and waste is critical for meeting both cost targets and regulatory requirements.

Waste contractors charge per drum or weight, with costs constantly rising due to new regulations. Simultaneously, facilities continue paying for new solvent. A solvent recovery system reduces both waste volumes and new solvent purchases. Most facilities achieve payback within 6-24 months while creating predictable operating costs despite fluctuating waste disposal fees.

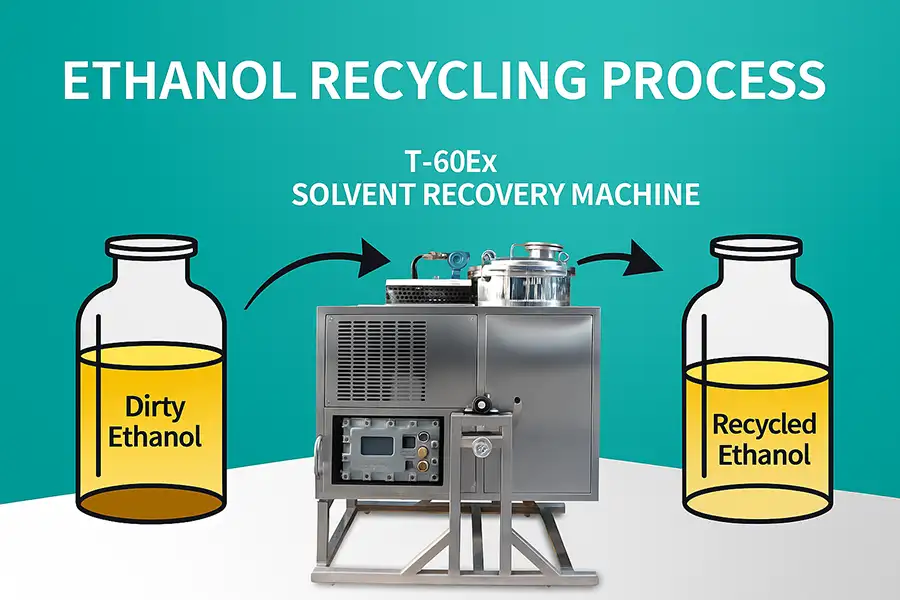

2 How Does a Paint Solvent Recovery System Work?

Professional-grade paint solvent recovery systems utilize thermal distillation technology: contaminated solvent is boiled, vapor rises to a condensation system, and purified liquid is collected for reuse, while contaminants remain in a disposable residue chamber.

Core Operational Phases

Filling: Waste paint solvent is pumped or poured into the heated boiler chamber

Heating: Electric heaters elevate temperature to the solvent's boiling point (typically 120-200°C)

Evaporation: Solvent vaporizes, separating from pigments, binders, and solid residues

Condensation: Vapors travel through a cooling system and return to liquid state

Collection: Purified solvent flows into dedicated clean containers for reuse

Residue Management: Dry material remains in a disposable liner bag for minimal disposal

Most industrial units feature ATEX-certified explosion-proof designs (Ex designation) specifically engineered for flammable solvents common in paint operations.

3 Business Advantages of Implementing Solvent Recovery

3.1 Comprehensive Cost Reduction

Operational savings provide the most compelling business case, focusing on two major expense categories:

Continuous procurement of virgin solvent

Escalating hazardous waste disposal expenses

Advanced paint solvent recovery technologies consistently achieve 95%+ recovery rates - meaning 100 liters of contaminated solvent yield approximately 95 liters of reusable solvent. This substantially reduces expense lines.

Absolutely. Small body shops and furniture manufacturers often achieve impressive ROI because disposal costs per drum are significant, especially for flammable waste. Compact systems with 20–60L capacity are specifically engineered for this scale. With waste disposal costs often exceeding $1-2 per pound, even modest operations can achieve payback in under 18 months. For comprehensive understanding of solvent waste management, see our solvent waste disposal guide.

3.2 Regulatory & Environmental Compliance

Beyond cost savings, solvent recovery delivers critical environmental benefits:

Hazardous waste reduction (fewer shipments off-site)

Lower overall VOC footprint by minimizing solvent production/transport

Enhanced regulatory compliance and support for ISO 14001 initiatives

The International Energy Agency reports that industrial resource efficiency measures like solvent recycling can deliver up to 25% of required emissions reductions in manufacturing sectors by 2030, underscoring its strategic importance.

3.3 Operational & Safety Improvements

Reliable solvent recovery delivers vital operational benefits:

Consistent cleaning quality for spray equipment and production systems

Minimized solvent storage requirements and associated safety risks

Reduced hazardous material handling and transportation incidents

Controlled waste stream management

For information on managing specialized wastes, see our guides on nitric acid disposal and methanol disposal.

4 Selecting Optimal Solvent Recovery System Capacity

System selection depends primarily on daily solvent utilization and operational workflow requirements. Below are specifications for industrial-grade solvent recyclers designed specifically for paint shop applications:

| Model | Capacity (L) | Power (kW) | Max Temp (°C) | Cycle Time (min) | Recovery Rate (%) | Dimensions (mm) |

|---|---|---|---|---|---|---|

| T-20Ex | 20 | 2 | 200 | ≈ 120 | 94-96 | 860 × 760 × 1190 |

| T-60Ex | 60 | 4 | 200 | ≈ 150 | 94-96 | 1160 × 870 × 1260 |

| T-80Ex | 80 | 5 | 200 | ≈ 180 | 94-96 | 1180 × 850 × 1290 |

| T-125Ex | 125 | 6 | 200 | ≈ 210 | 94-96 | 1250 × 920 × 1450 |

| T-250Ex | 250 | 16 | 200 | ≈ 240 | 94-96 | 2600 × 1200 × 1950 |

| T-400Ex | 400 | 32 | 200 | ≈ 270 | 94-96 | 1990 × 1850 × 2090 |

4.1 Implementation in Small/Medium Facilities

For automotive repair centers, custom fabrication shops, and furniture finishing operations, models like T‑20Ex & T‑60Ex offer ideal capacity. These are typically operated once daily or per shift, matching standard gun cleaning volumes.

4.2 Production-Scale Implementations

For continuous industrial coating lines and multiple finishing stations, systems like T‑125Ex, T‑250Ex & T‑400Ex handle significant volumes and can integrate with automated cleaning systems.

Batch processing represents the most efficient approach for most operations. Contaminated solvent accumulates in intermediate containers until reaching the recycler's capacity (without exceeding maximum fill levels). This practice maximizes operational efficiency, recovery rates, and minimizes labor requirements.

For detailed technical explanations of solvent recovery engineering, explore our specialist resource on solvent recovery technology principles.

5 Industrial Safety & Practical Implementation

Given the flammable nature of paint solvents, safety engineering is non-negotiable. Explosion-proof solvent recovery systems feature multi-layered safeguards:

Multi-point temperature controls with redundant protection

Automatic pressure relief mechanisms

Integrated grounding systems preventing static discharge

Sealed vapor containment systems

Continuous atmospheric monitoring

Proper industrial ventilation, professional electrical installation (NEC/CEC compliance), and operator training remain essential requirements regardless of equipment design.

Facilities handling aggressive chemicals beyond standard solvents must implement specialized protocols. Our guides on methanol disposal and xylene handling provide specialized implementation advice.

6 Strategic Implementation Opportunities

Solvent recovery delivers maximum value when:

Consistent solvent-based cleaning operations exist

Hazardous waste expenses exceed $500 monthly

Environmental compliance presents regulatory challenges

Available facilities/safety infrastructure support implementation

Operator training programs can incorporate new equipment

Conversely, facilities with minimal solvent usage (

Execute Your Solvent Recovery Strategy

Implementing a paint solvent recovery solution transitions waste management from liability to strategic advantage. With typical recovery rates exceeding 90-95%, most facilities achieve full return on investment within 6-24 months while strengthening environmental compliance programs.

Critical implementation steps include:

Quantify current solvent purchasing costs and waste disposal volumes

Calculate potential savings using conservative projection models

Match technical requirements to available capacity solutions

Develop implementation timeline with safety integration protocols

Explore industrial-grade equipment solutions through our comprehensive solvent recycler listing featuring technical specifications and application profiles.

Explore Industrial Solvent Recyclers