Nitric acid is a powerful chemical widely used in industries like metal processing, electronics manufacturing, laboratory research, and pharmaceuticals. While it’s invaluable for these applications, improper disposal of nitric acid poses serious risks to human health, equipment, and the environment. If your business uses nitric acid, you’ve probably wondered: How do I dispose of it safely? What are the regulations? Are there cost-effective solutions?

This guide answers these questions while introducing a game-changing tool for businesses: solvent recycling machines. As a trusted manufacturer of solvent recyclers for global markets, we’ll explain how our technology simplifies nitric acid disposal, reduces costs, and aligns with sustainability goals. Let’s dive in!

Why Proper Nitric Acid Disposal Matters

Before discussing disposal methods, let’s understand why safe handling is non-negotiable:

Health Hazards:

Nitric acid is corrosive and can cause severe burns, respiratory issues, or eye damage. Even diluted solutions require careful handling.

Environmental Impact:

Dumping nitric acid into drains or soil contaminates water sources, harms ecosystems, and violates environmental laws.

Legal Compliance:

Governments enforce strict regulations (e.g., EPA in the U.S., REACH in the EU) for hazardous waste disposal. Non-compliance leads to fines or operational shutdowns.

Cost of Waste Management:

Hiring third-party disposal services is expensive, especially for businesses generating large volumes of waste.

Traditional Nitric Acid Disposal Methods (and Their Downsides)

Most businesses rely on these conventional methods, but they come with drawbacks:

1. Neutralization

Process: Mixing nitric acid with a base (e.g., sodium bicarbonate) to neutralize its acidity.

Problems:

Produces saltwater, which may still contain toxic residues.

Requires precise pH monitoring to avoid incomplete neutralization.

Generates large amounts of neutralized waste needing further disposal.

2. Dilution and Discharge

Process: Diluting nitric acid with water until it’s “safe” for drain disposal.

Problems:

Illegal in most regions without permits.

Risks pipe corrosion and groundwater pollution.

Doesn’t eliminate the acid’s hazardous nature.

3. Off-Site Disposal Services

Process: Hiring waste management companies to collect and treat nitric acid.

Problems:

High recurring costs.

Logistical delays and dependency on third parties.

Limited transparency in disposal practices.

These methods are either risky, inefficient, or costly. Fortunately, there’s a smarter alternative: recycling nitric acid with a solvent recycling machine.

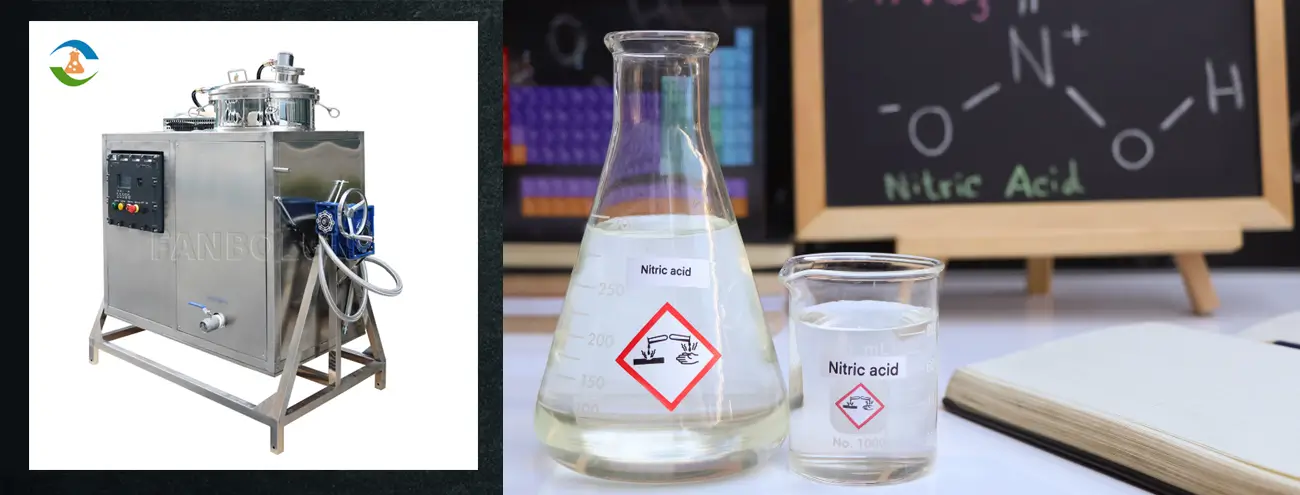

The Better Solution: Recycling Nitric Acid with a Solvent Recycler

Solvent recyclers are innovative devices that purify and recover used nitric acid, allowing businesses to reuse it multiple times. Here’s why this method is gaining popularity globally:

How Does a Solvent Recycler Work?

Collection: Waste nitric acid is collected in a dedicated container.

Distillation: The machine heats the acid to separate pure nitric acid from contaminants.

Recovery: The purified acid is condensed and stored for reuse.

Residue Management: A small amount of non-recyclable residue remains, which is safer and cheaper to dispose of.

Benefits of Recycling Nitric Acid

Cost Savings: Reduce purchases of fresh nitric acid by up to 90%.

Waste Reduction: Slash disposal costs and hazardous waste volume.

Eco-Friendly: Minimize environmental harm and carbon footprint.

Compliance: Simplify adherence to waste disposal regulations.

Safety: Avoid handling hazardous waste during transportation or neutralization.

Solvent Recycling Equipment (90L)

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Solvent Recycler Machine (125L)

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Solvent Recycling Machine (250L)

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Recovery(%): 95

View More

Solvent Recycling System (600L)

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Recovery(%): 95

View More

Key Features to Look for in a Solvent Recycling Machine

Not all recyclers are created equal. When choosing a machine for nitric acid, prioritize these features:

Corrosion-Resistant Materials: Nitric acid is highly corrosive. Ensure the recycler uses materials like PTFE, glass-lined steel, or specialized alloys.

Automated Controls: User-friendly interfaces and preset programs reduce human error and training time.

Safety Mechanisms: Look for leak detectors, emergency cooling, and explosion-proof designs.

Energy Efficiency: Machines with low energy consumption cut operational costs.

Scalability: Choose a capacity (e.g., 10L to 200L batches) that matches your daily waste volume.

Step-by-Step: How to Dispose of Nitric Acid Using a Recycler

Let’s break down the process to show how simple it is:

Waste Collection: Store used nitric acid in labeled, acid-resistant containers.

Pre-Treatment (Optional): Filter out solid impurities to protect the recycler.

Load the Machine:Transfer the waste into the recycler’s boiler.

Start the Cycle: Activate the distillation program. The machine heats the acid, vaporizing the pure solvent while leaving contaminants behind.

Recover and Reuse: Collect the distilled nitric acid in a clean container. Test its purity before reuse.

Residue Disposal: Safely discard the minimal leftover sludge (now less hazardous) via approved methods.

Common Questions About Nitric Acid Recycling

Q: Is recycled nitric acid as effective as new acid?

A: Yes! Distillation removes impurities, restoring the acid’s concentration and quality.

Q: What about nitric acid mixed with other solvents?

A: Advanced recyclers can separate nitric acid from mixtures using fractional distillation.

Q: Can small businesses afford a solvent recycler?

A: Absolutely. Consider the long-term savings from reduced disposal and solvent costs. Many machines pay for themselves within 6–12 months.

Q: How do I maintain the recycler?

A: Regular cleaning and part inspections (e.g., seals, heating elements) ensure longevity. Reputable suppliers offer training and support.

Real-World Success: Case

Case 1: Metal Plating Factory in Germany

Challenge: High nitric acid consumption (500L/month) and steep disposal fees.

Solution: Installed a 100L-capacity recycler.

Result: Reduced fresh acid purchases by 85% and achieved ROI in 8 months.

Case 2: University Laboratory in Canada

Challenge: Strict safety protocols for nitric acid waste.

Solution: Adopted a compact, automated recycler.

Result: Eliminated off-site disposal needs and enhanced lab safety.

Conclusion: Turn Waste into Savings with a Solvent Recycler

Disposing of nitric acid doesn’t have to be expensive, risky, or harmful to the planet. By investing in a solvent recycling machine, your business can:

✅ Save money on solvent purchases and waste management.

✅ Protect workers and the environment.

✅ Streamline compliance with global regulations.

As a leading exporter of solvent recyclers, we provide tailored solutions for industries worldwide. Our machines are built to handle corrosive chemicals like nitric acid, ensuring durability, safety, and maximum efficiency.

Ready to Transform Your Waste Management Process?

Contact us today to learn how our solvent recyclers can be customized for your needs. Let’s work together to make your operations safer, greener, and more profitable!