Solvent recovery systems are crucial for industries that use solvents in their processes. These systems allow for the collection, purification, and reuse of solvents, which otherwise would be disposed of, leading to environmental concerns and financial losses. Understanding how a solvent recovery system works can highlight its importance and efficiency, providing insights into its benefits for both the environment and businesses.

What is a Solvent Recovery System?

A solvent recycling system is designed to capture and recycle solvents from industrial processes. These solvents are often used in large quantities in various industries such as pharmaceuticals, chemicals, coatings, and more. The primary purpose of these systems is to purify and reclaim the solvents for reuse, reducing waste and the need for fresh solvents.

How Does a Solvent Recovery System Work?

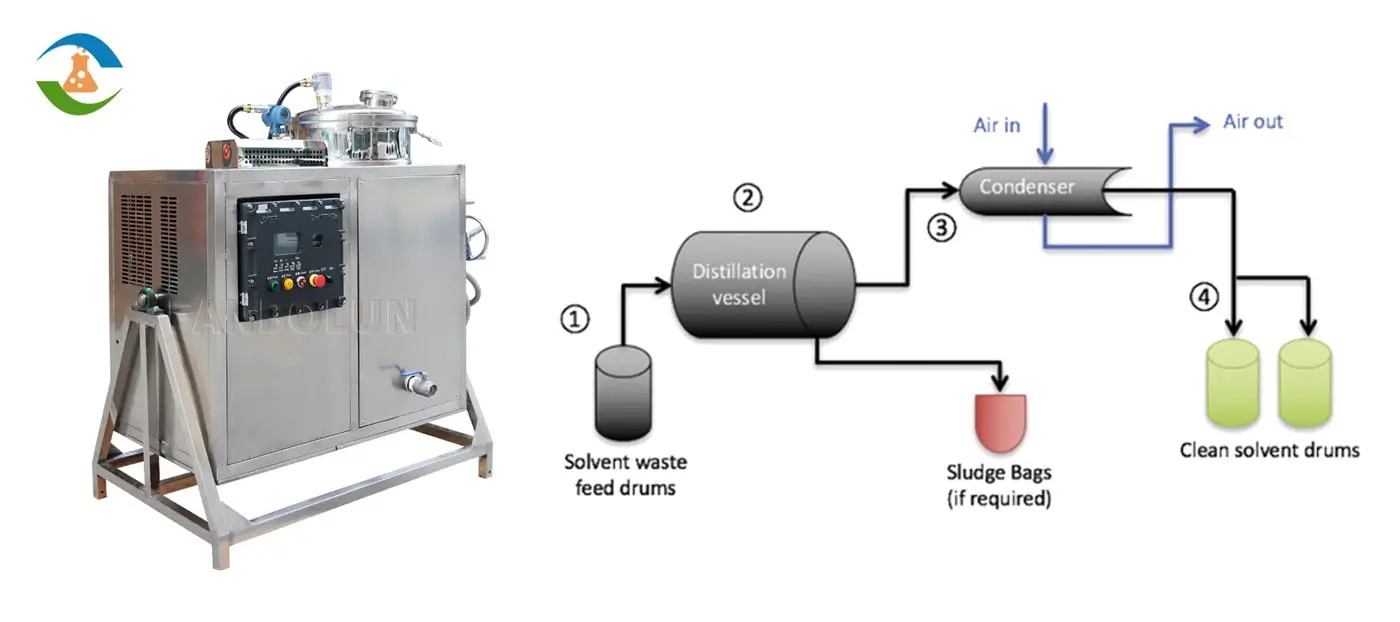

The working principle of a solvent recovery system involves several key steps: collection, distillation, condensation, and storage. Each of these steps plays a vital role in ensuring the efficient recovery and reuse of solvents.

Collection

The first step in the solvent recovery process is the collection of spent solvents. These solvents are usually contaminated with impurities and need to be separated for effective recovery. The contaminated solvent is collected from various sources within the industrial process, such as cleaning operations, manufacturing processes, and chemical reactions.

Distillation

Once collected, the solvent undergoes distillation. Distillation is the core process in solvent recovery systems. It involves heating the contaminated solvent to its boiling point. As the solvent evaporates, it separates from the impurities and other components that have different boiling points.

Have you ever wondered how distillation can effectively separate solvents from contaminants? The principle is based on the fact that different substances have different boiling points. By carefully controlling the temperature, the solvent can be evaporated and then condensed back into its pure form, leaving behind the impurities.

Condensation

After the solvent is evaporated, it needs to be condensed back into a liquid form. This is achieved through a cooling process where the vaporized solvent passes through a condenser. The condenser cools down the vapor, turning it back into a liquid state. The purified solvent is then collected for further use.

Storage

The final step in the process is the storage of the recovered solvent. The purified solvent is stored in dedicated tanks or containers, ready to be reused in the industrial process. Proper storage is crucial to maintain the quality and purity of the recovered solvent.

Advantages of Solvent Recovery Systems

Solvent recovery systems offer numerous advantages, making them a valuable addition to any industry that relies heavily on solvents. These benefits can be broadly categorized into environmental, economic, and operational advantages.

Environmental Benefits

One of the most significant advantages of solvent recovery systems is their positive impact on the environment. By recovering and reusing solvents, industries can significantly reduce their solvent waste. This leads to less environmental pollution and a lower carbon footprint. Additionally, it minimizes the need for fresh solvents, conserving natural resources and promoting sustainability.

Economic Benefits

From an economic perspective, solvent recovery systems can lead to substantial cost savings. The cost of purchasing fresh solvents can be high, especially when used in large quantities. By recovering and reusing solvents, businesses can reduce their procurement costs. Moreover, the reduced waste disposal costs further contribute to overall savings.

Did you know that investing in a solvent recovery system can yield a quick return on investment? The initial cost of setting up the system is often offset by the savings on solvent purchases and waste disposal, making it a financially sound decision for many businesses.

Operational Benefits

Solvent recovery systems can also enhance operational efficiency. By reusing solvents, industries can maintain a consistent supply, reducing the risk of disruptions caused by solvent shortages. Additionally, the quality of recovered solvents is often high, ensuring that they can be effectively used in various processes without compromising on performance.

Types of Solvent Recovery Systems

There are different types of solvent recovery systems available, each designed to cater to specific needs and applications. Some common types include:

Batch Distillation Systems

Batch distillation systems are suitable for processes where solvents are used in smaller quantities or where the solvent composition varies. These systems operate in cycles, allowing for the recovery of solvents in batches.

Continuous Distillation Systems

Continuous distillation systems are ideal for processes that require the continuous recovery of solvents. These systems operate continuously, providing a steady supply of recovered solvents. They are often used in large-scale industrial operations.

Vacuum Distillation Systems

Vacuum distillation systems are used for solvents with high boiling points. By reducing the pressure, these systems lower the boiling point of the solvent, making it easier to distill and recover. This method is particularly useful for heat-sensitive solvents.

Applications of Solvent Recovery Systems

Solvent recovery systems are used across various industries due to their versatility and efficiency. Some common applications include:

Pharmaceutical Industry

In the pharmaceutical industry, solvents are extensively used in the manufacturing of drugs and other medical products. Solvent recovery systems help in reclaiming these solvents, ensuring that they can be reused in the production process. This not only reduces costs but also ensures compliance with environmental regulations.

Chemical Industry

The chemical industry relies heavily on solvents for various reactions and processes. Solvent recovery systems enable the purification and reuse of these solvents, maintaining the quality of chemical products and reducing waste.

Coatings and Paints Industry

Solvents are essential in the production of coatings and paints. Solvent recovery systems help in recovering solvents used in cleaning equipment and manufacturing processes, leading to cost savings and reduced environmental impact.

Food and Beverage Industry

In the food and beverage industry, solvents are used for extraction and purification processes. Solvent recovery systems ensure that these solvents can be reused, maintaining the quality and safety of food products.

Challenges and Considerations

While solvent recovery systems offer numerous benefits, there are also some challenges and considerations to keep in mind.

Initial Investment

The initial investment for setting up a solvent recovery system can be significant. Businesses need to consider the cost of equipment, installation, and maintenance. However, the long-term savings and environmental benefits often outweigh the initial expenses.

Maintenance and Operation

Solvent recovery systems require regular maintenance to ensure their efficient operation. This includes cleaning, inspection, and replacement of parts as needed. Proper training for operators is also essential to maintain the system's performance.

Regulatory Compliance

Industries need to ensure that their solvent recovery systems comply with environmental regulations and standards. This includes proper handling, storage, and disposal of recovered solvents and waste products.

Conclusion

Solvent recovery systems play a crucial role in promoting sustainability and efficiency in various industries. By understanding how these systems work, businesses can make informed decisions about implementing solvent recovery processes. The benefits of reduced environmental impact, cost savings, and improved operational efficiency make solvent recovery systems a valuable investment.

Have you considered the long-term benefits of a solvent recovery system for your industry? The positive impact on both the environment and your bottom line can be substantial, making it a worthwhile consideration for any business that relies on solvents.