In industrial and laboratory settings, solvents play crucial roles in various processes such as chemical synthesis, cleaning, and degreasing. However, the disposal of solvent waste poses significant environmental and health challenges. Mishandling solvent waste can lead to hazardous emissions, soil and water contamination, and serious health risks to workers and nearby communities. Effective solvent waste management is paramount, and one of the most efficient methods for managing solvent waste is through the use of a solvent recovery machine.

Understanding Solvent Waste

Solvent waste refers to any leftover or spent solvents that are no longer suitable for their intended use. This waste can contain hazardous compounds and pose various risks. Common solvents include acetone, methanol, ethanol, toluene, and xylene, among others. Due to their volatile nature, improper disposal can result in the release of toxic vapors, increasing the risk of fire and explosion.

Traditional Disposal Methods

Traditional methods of solvent disposal often involve incineration or sending the waste to landfills. While these methods may effectively eliminate the immediate presence of hazardous solvents, they have significant drawbacks:

Incineration: Although incineration can destroy hazardous chemicals, it generates harmful emissions, including greenhouse gases and toxic pollutants, contributing to air pollution and climate change.

Landfilling: Disposing of solvents in landfills can lead to soil and groundwater contamination as the chemicals leach out over time. This method is also unsustainable due to the increasing scarcity of landfill space.

Given these drawbacks, alternative and more sustainable methods for solvent waste management are essential.

Solvent Recovery: A Sustainable Solution

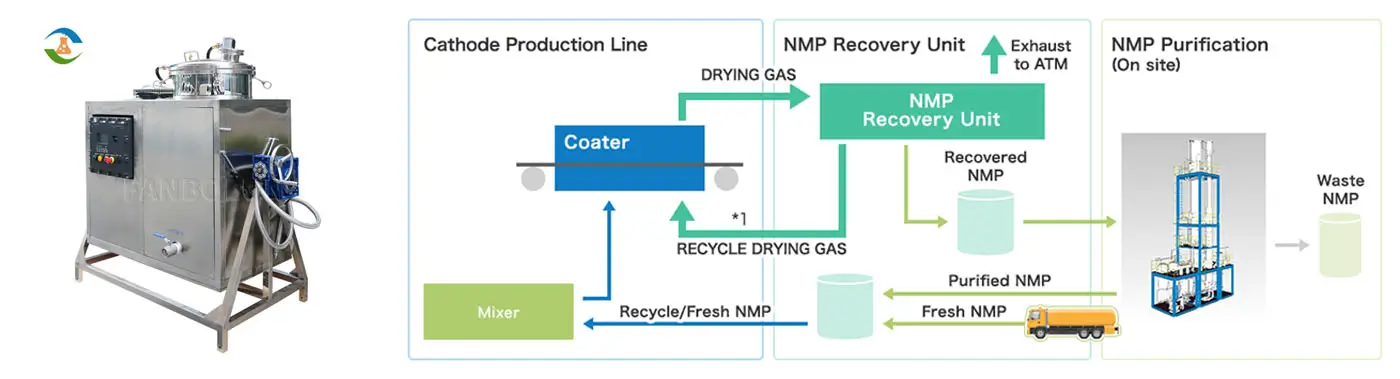

One of the most effective and environmentally friendly methods for solvent waste management is solvent recovery. This process involves reclaiming and reusing spent solvents, significantly reducing the need for new solvent production and minimizing waste.

What is a Solvent Recovery Machine?

A solvent recovery machine is designed to reclaim and purify used solvents, enabling their reuse in industrial and laboratory processes. These machines operate through distillation, separating the solvent from impurities and contaminants.

Solvent Recycling Equipment (90L)

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Solvent Recycler Machine (125L)

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Solvent Recycling Machine (250L)

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Recovery(%): 95

View More

Solvent Recycling System (600L)

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Recovery(%): 95

View More

How Does It Work?

The operation of a solvent recovery machine can be broken down into several steps:

Collection: Solvent waste is collected in a designated container.

Heating: The solvent waste is heated in a distillation chamber.

Evaporation: As the solvent heats up, it evaporates, leaving behind impurities and contaminants.

Condensation: The vaporized solvent is then passed through a cooling system where it condenses back into a liquid.

Collection: The purified solvent is collected in a separate container, ready for reuse.

Advantages of Using a Solvent Recovery Machine

Environmental Benefits

Using a solvent recovery machine has significant environmental advantages:

Reduction in Hazardous Waste: By reclaiming solvents, the volume of hazardous waste generated is significantly reduced, minimizing the potential for environmental contamination.

Lower Emissions: Solvent recovery reduces the need for incineration, thus decreasing the release of harmful emissions.

Resource Conservation: Reusing solvents decreases the demand for raw materials, conserving natural resources and reducing the environmental impact of solvent production.

Economic Benefits

From an economic perspective, solvent recovery machines offer several advantages:

Cost Savings: Reusing solvents reduces the need to purchase new solvents, leading to substantial cost savings over time.

Waste Disposal Costs: By reducing the volume of waste, companies can lower their waste disposal costs.

Regulatory Compliance: Proper solvent recovery can help companies comply with environmental regulations, avoiding potential fines and legal issues.

Have you ever considered how much solvent waste is generated monthly and the potential cost savings from a solvent recovery system?

Evaluating the amount of solvent waste generated can provide valuable insights into the potential cost savings from implementing a solvent recovery system. Conducting a waste audit can help determine the volume of waste and the potential reduction in solvent purchase costs and waste disposal fees.

Health and Safety Benefits

Solvent recovery also enhances health and safety in the workplace:

Reduced Exposure: By managing solvent waste more effectively, the risk of worker exposure to hazardous chemicals is reduced.

Fire and Explosion Prevention: Proper handling and recovery of solvents minimize the risk of fires and explosions caused by volatile organic compounds.

What steps can be taken to ensure the safety of workers when operating a solvent recovery machine?

Proper training on the operation and maintenance of the recovery machine.

Implementing safety protocols, such as wearing personal protective equipment (PPE) and ensuring adequate ventilation.

Regular maintenance and inspections to prevent equipment malfunctions and leaks.

Clear labeling and proper storage of solvents and recovered materials to prevent accidental exposure or mixing of incompatible substances.

Implementing Solvent Recovery

Implementing a solvent recovery system requires careful planning and consideration. Here are some steps to ensure successful implementation:

Assessment: Evaluate the types and volumes of solvents used and generated in your processes.

Selection: Choose a solvent recovery machine that matches your specific needs in terms of capacity, compatibility, and efficiency.

Installation: Ensure proper installation of the recovery machine, including appropriate ventilation and safety measures.

Training: Provide thorough training for staff on operating and maintaining the recovery machine.

Monitoring: Regularly monitor the performance of the solvent recovery system to ensure optimal operation and identify any potential issues.

What factors should be considered when selecting a solvent recovery machine for specific needs?

When selecting a solvent recovery machine, consider the types of solvents being used, the volume of waste generated, and the capacity required for efficient operation. Additionally, evaluate the machine's compatibility with existing processes and its overall efficiency in reclaiming solvents.

Other Methods of Solvent Waste Management

While solvent recovery is highly effective, it is also important to consider other methods of managing solvent waste:

Recycling

Solvent recycling involves the use of external services to reclaim and purify solvents. Companies specializing in solvent recycling can handle large volumes of waste and ensure compliance with environmental regulations. This method is suitable for facilities that may not have the capacity to install their own recovery machines.

Substitution

Another approach is the substitution of hazardous solvents with less harmful alternatives. By using greener solvents, companies can reduce the risks associated with solvent waste. Research and development into alternative solvents are ongoing, and many safer options are becoming available on the market.

Minimization

Solvent waste minimization focuses on reducing the amount of solvent used in processes. This can be achieved through process optimization, improved equipment design, and the adoption of best practices. For instance, precision dispensing equipment can minimize solvent use in cleaning operations, while closed-loop systems can reduce solvent losses.

Conclusion

Effective solvent waste management is crucial for protecting the environment, ensuring workplace safety, and achieving cost savings. Among the various methods available, solvent recovery stands out as a highly efficient and sustainable solution. By investing in a solvent recovery machine, companies can reclaim valuable solvents, reduce hazardous waste, and contribute to a cleaner and safer environment.

Is it time to take the next step in solvent waste management? Evaluate solvent use and waste generation, and consider the benefits of implementing a solvent recovery system. This can improve the bottom line, make a positive impact on the environment, and enhance workplace safety. Reach out to a team of experts to learn more about how solvent recovery can work for different needs.