Solvent Recovery for Coatings: A Practical Guide to Cutting Cost and Waste

Coating lines use large volumes of solvents for thinning, cleaning and flushing equipment. This article explains in clear, non‑technical language how solvent recovery for coatings works, what recovery rates are realistic, and when a solvent recycler machine actually pays back.

1. Why solvent recovery matters in coatings

Coatings, paints, inks and varnishes rely heavily on organic solvents such as acetone, xylene, toluene, MEK and alcohols. These substances are used to thin coatings to the right viscosity and to clean spray guns, lines and mixing tanks.

For many plants, solvent cost and disposal are not just technical issues; they hit the bottom line every month. The World Economic Forum has reported that chemical and materials companies could reduce operating costs by 10–15% through better circular use of solvents and raw materials. Solvent recovery for coatings is one of the most direct ways to capture part of that potential.

Typical pain points in coating operations

High spend on fresh solvent for thinning and cleaning.

Growing volumes of hazardous waste that must be shipped off‑site.

Stricter environmental regulations and VOC limits.

Pressure from customers to demonstrate sustainable practices.

Solvent recovery systems address these issues by turning dirty solvent back into clean, reusable solvent. Instead of paying twice—once to buy solvent and again to dispose of it—plants use the same material multiple times.

Question: Does solvent recovery for coatings only make sense for very large factories?

Answer: No. While high‑volume automotive or coil‑coating plants see the fastest payback, even mid‑sized metal shops, wood finishing lines or printing companies with a few hundred liters of solvent waste per month can justify a compact solvent recycler machine. The key is the annual volume of waste solvent and the current cost of buying and disposing of it, not just the physical size of the facility.

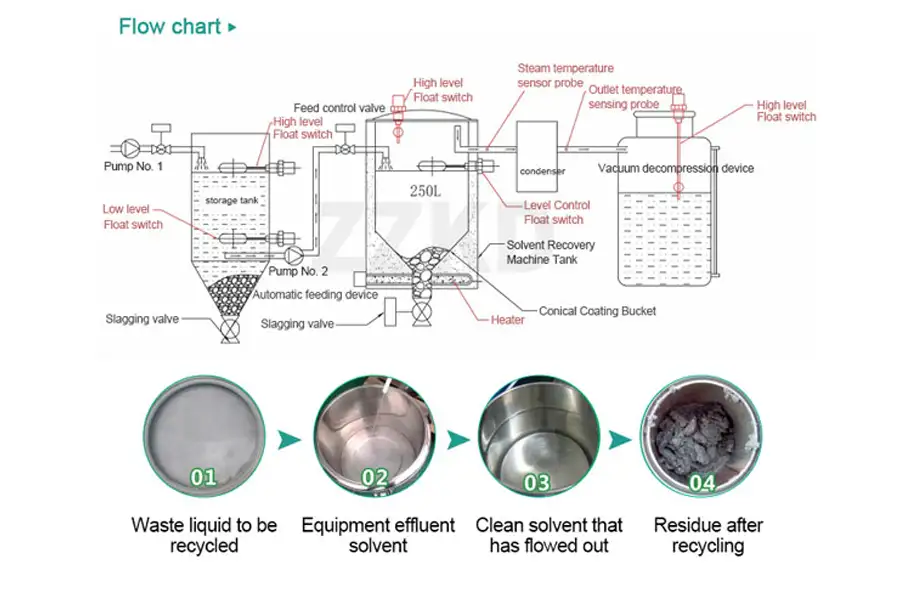

2. How solvent recovery for coatings actually works

In most coating applications, solvent recovery is based on distillation. The idea is simple: the solvent boils at a lower temperature than the resins, pigments and heavy contaminants. A solvent recovery machine heats the dirty solvent, evaporates the clean solvent vapor, then condenses it back into liquid.

Fill the distillation tank with dirty solvent from gun washers, flushing lines or mixing vessels.

Heat the batch using an electric heating jacket; the solvent boils and turns to vapor.

Cool the vapor in a condenser; the solvent returns to a clean liquid state.

Collect clean solvent in a separate container, ready for re‑use in thinning or cleaning.

Remove residue (coating resins, pigments, sludge) from a liner bag or the bottom of the tank.

According to a study published by the European Chemicals Agency, simple batch distillation can recover 80–95% of many organic solvents from typical paint and coating residues, depending on contamination and operating conditions. Modern solvent recyclers used in the coatings industry are designed to consistently reach the upper end of that range for common cleaning blends.

For readers who want more background on recovery principles beyond coatings, an in‑depth explanation of system design is available here:how does a solvent recovery system work.

Question: Will recovered solvent actually clean as well as fresh solvent?

Answer: If the distillation is operated within the recommended temperature range and the solvent blend is compatible with batch recycling, the recovered solvent normally has very similar cleaning power and evaporation behavior. Many coating plants use recycled solvent for gun cleaning and line flushing, while reserving fresh solvent for critical thinning steps that directly affect coating appearance or cure properties.

3. Typical capacities & recovery rates for coating solvents

To make solvent recovery for coatings practical, the equipment must match the scale of the operation. Below are example specifications of explosion‑proof solvent recovery units commonly used in paint and coating environments.

| Model | Feed Capacity (L) | Power Supply (ACV) | Heating Power (kW) | Temperature Range (℃) | Typical Treatment Time (min) | Recovery (%) | Machine Weight (kg) | Machine Size (mm) |

|---|---|---|---|---|---|---|---|---|

| T-20Ex | 20 | 380 | 2 | RT–200 | 120 | 95 | 153 | 860 × 760 × 1190 |

| T-60Ex | 60 | 380 | 4 | RT–200 | 150 | 95 | 170 | 1160 × 870 × 1260 |

| T-80Ex | 80 | 380 | 5 | RT–200 | 180 | 95 | 200 | 1180 × 850 × 1290 |

| T-125Ex | 125 | 380 | 6 | RT–200 | 210 | 95 | 280 | 1250 × 920 × 1450 |

| T-250Ex | 250 | 380 | 16 | RT–200 | 240 | 95 | 520 | 2600 × 1200 × 1950 |

| T-400Ex | 400 | 380 | 32 | RT–200 | 270 | 95 | 1200 | 1990 × 1850 × 2090 |

For coating operations, these capacities translate into practical usage patterns:

20–80 L – suited to small paint shops, furniture finishing, or low‑volume ink lines.

125–250 L – common for regional coating manufacturers and OEM paint lines.

400 L+ – used where there are multiple coating lines or centralized solvent waste collection.

In all these cases, a well‑operated system can regularly achieve recovery rates around 95% for common coating solvents, meaning that out of 100 liters of dirty solvent, about 95 liters become reusable and 5 liters remain as concentrated residue.

Question: Is it better to run many small batches or fewer large batches of solvent waste?

Answer: From an energy and labor perspective, fewer, larger batches are usually more efficient—as long as the waste stream is reasonably homogeneous and compatible. However, in job‑shop environments where different coatings and colors change frequently, smaller batches help avoid cross‑contamination. In practice, plants often standardize on 1–2 solvent blends for cleaning to make recovery simpler and more efficient.

4. When does a solvent recycling system make sense?

The decision to invest in solvent recovery for coatings is usually based on a straightforward financial calculation. A report by the U.S. Environmental Protection Agency notes that many in‑plant solvent recycling projects in the coatings and printing sectors achieve payback periods between 6 and 24 months, primarily through reduced solvent purchase and lower hazardous waste disposal fees.

4.1 Key factors in the business case

Current annual solvent consumption (thinning + cleaning).

Annual volume of solvent waste sent off‑site.

Purchase price per liter of solvent.

Disposal cost per liter of waste solvent (transport + treatment).

Labor time spent handling drums and scheduling pickups.

As a rule of thumb, if a plant generates more than 400–600 L/month of recyclable solvent waste, it is worth running a simple payback analysis on a solvent recycling system.

4.2 Simple example for a coating line

Consider a medium‑sized metal coating line:

Fresh solvent cost: 2.5 USD/L.

Waste disposal cost: 1.2 USD/L.

Waste solvent volume: 1,000 L/month.

Recovery rate: 90% usable solvent.

In this scenario:

Recovered solvent: 900 L/month, reducing fresh solvent purchase by 2,700 USD/month.

Waste volume reduced to ~100 L/month, cutting disposal cost from 1,200 USD to 120 USD.

Combined, this is approximately 3,780 USD/month in avoided cost. Even after electricity, maintenance and liner bags, many plants see net savings that justify a solvent recovery unit within one to two years.

5. Solvent purity, safety & compliance

In coatings, solvent quality affects more than cleaning; it can influence film appearance, drying time and adhesion. That is why plants often differentiate between “recovered for cleaning” and “fresh for formulation.”

5.1 Purity considerations for coating solvents

Recovered solvent from coatings is usually reused for:

Flushing spray guns and hoses between color changes.

Cleaning mixers, tanks and small tools.

Pre‑rinsing parts before final cleaning.

For solvent that goes directly into coating formulations, many manufacturers prefer to either:

Blend a small percentage of recycled solvent into fresh solvent, or

Use recycled solvent only in non‑critical or primer formulations.

5.2 Safety and EX‑proof design

Because coating solvents are often flammable, industrial solvent recovery machines for this sector are usually explosion‑proof. Typical safety features include:

EX‑rated electrical components and controls.

Over‑temperature and level protection to avoid dry heating.

Grounding and bonding to prevent static buildup.

Closed‑loop operation to minimize solvent vapors in the room.

For readers dealing with broader solvent waste streams (beyond coatings) and compliance topics, it may be useful to review this overview article:how to dispose of solvent waste.

6. Getting started with solvent recovery for coatings

Implementing solvent recovery for coatings does not have to be complex. Most projects follow a simple three‑step path: analyze the waste stream, select the right capacity, and integrate the unit into daily operations.

6.1 Understand the solvent waste stream

Before selecting equipment, clarify:

Which solvents are present (e.g., xylene, acetone, mixed aromatic blends).

How much comes from cleaning vs. from overspray or sludge.

Whether different waste streams need to be kept separate.

6.2 Choose a suitable solvent recycler machine

Match the daily or weekly waste volume to an appropriate batch size. For example, if a plant generates about 250–300 L of cleaning solvent per day, a 125–250 L batch model allows one or two cycles per day with reasonable operator time.

To review detailed equipment options, capacities and configurations, see:solvent recycling machine.

6.3 Integrate into coating line operations

In practice, solvent recovery for coatings works best when it is built into existing workflows:

Place the unit near the gun washers or cleaning area to minimize drum handling.

Standardize on 1–2 cleaning blends suitable for recycling across lines.

Use disposable liners to make residue removal clean and fast.

Track recovered volumes and disposal reductions to document savings and ESG benefits.

According to industry benchmarking by several national paint and coatings associations, companies that adopt in‑house solvent recovery often report solvent purchase reductions of 50–80% for cleaning operations, with corresponding cuts in hazardous waste volumes. This combination of economic and environmental benefit is why solvent recovery for coatings is increasingly viewed as standard good practice rather than an optional add‑on.