Are you accumulating hazardous solvent waste in your lab? Improper handling creates safety risks, environmental damage, and can lead to hefty fines if regulations aren't followed.

Solvent waste is typically disposed of by careful segregation, labeling, and collection in designated containers, followed by pickup from a licensed hazardous waste disposal company. Regulations vary globally but emphasize safety and environmental protection.

As a manufacturer dealing with labs worldwide, we know solvent waste is a big concern. Many of our customers using equipment like rotary evaporators or reactors generate significant solvent waste. Handling it correctly isn't just about rules; it's about keeping people safe and protecting our planet. Let's break down the common practices and options available to labs and industries.

What does proper solvent waste management involve?

Confused about the specific steps for managing solvent waste safely and legally? Overlooking key procedures like segregation or labeling can lead to dangerous situations or compliance issues.

Proper solvent waste management involves segregating different types of solvents (e.g., halogenated vs. non-halogenated), using appropriate, clearly labeled containers, storing them safely away from ignition sources, and documenting waste streams before professional disposal.

Effective solvent waste management is crucial in any facility using chemicals. It's not just about getting rid of the waste; it's a systematic approach to minimize risk from the moment the waste is generated until its final disposal. Based on our experience supporting labs globally, here are the essential components:

1. Segregation: Don't Mix!

This is often the first and most critical step. Mixing incompatible wastes can cause dangerous reactions (heat, gas, fire). Also, disposal costs often depend on the waste type. Common segregation categories include:

Halogenated Solvents: Contain chlorine, bromine, fluorine, or iodine (e.g., dichloromethane, chloroform). Often more expensive to dispose of.

Non-Halogenated Solvents: Do not contain halogens (e.g., ethanol, acetone, hexane, ethyl acetate).

Acids/Bases: Should generally be neutralized before disposal or kept separate.

Heavy Metals: Solutions containing toxic metals require special handling.

Water/Aqueous Waste: Keep separate from organic solvents unless specifically part of a process waste stream.

2. Containment: Use the Right Containers

Waste solvents must be stored in containers compatible with the chemicals they hold. Use containers specifically designated for waste, never food or drink containers. Ensure they have secure caps to prevent spills and evaporation. Don't overfill – leave headspace (around 10-15%) for expansion.

3. Labeling: Clear and Accurate Information

Every waste container must be clearly labeled with:

| Label Information | Importance |

| "Hazardous Waste" (or equivalent term per local regulation) | Immediately identifies the container's contents as dangerous. |

| Full Chemical Names of Contents | Essential for safe handling and disposal company assessment. Avoid abbreviations. |

| Approximate Percentages/Concentrations | Helps determine hazard level and disposal method. |

| Accumulation Start Date | Often required by regulations to track storage time limits. |

| Responsible Person/Department | Provides a point of contact. |

4. Storage: Safety First

Store waste containers in a designated, well-ventilated area, away from heat, sparks, open flames, and incompatible materials. Use secondary containment (like spill trays) to catch potential leaks.

5. Disposal: Use Licensed Professionals

Never pour solvent waste down the drain or dispose of it with regular trash. Contract with a certified hazardous waste disposal company. They have the permits and expertise to transport and treat or dispose of the waste according to strict environmental regulations. Keep detailed records of all waste shipments (manifests).

Following these steps diligently minimizes risks and ensures compliance, something we always emphasize to users of our equipment.

Is solvent waste recycling a viable option for your facility?

Drowning in solvent disposal costs and concerned about environmental impact? Exploring recycling could offer significant savings and boost your sustainability efforts, but is it practical for you?

Solvent waste recycling is often viable, especially for relatively pure, single-solvent streams. It involves purifying used solvents (often through distillation) for reuse, reducing both disposal costs and the need to purchase new solvent. Feasibility depends on solvent type, contamination level, and volume.

Recycling solvents instead of disposing of them is an increasingly attractive option for many businesses we work with, driven by both cost savings and environmental responsibility. Think about it: you reduce the expense of hazardous waste disposal *and* cut down on purchasing virgin solvent. But it's not always straightforward.

How Does Solvent Recycling Work?

The most common method is distillation. The waste solvent is heated, the solvent vaporizes, it's then condensed back into liquid form, leaving contaminants behind. The effectiveness depends heavily on the difference in boiling points between the solvent and the contaminants.

Options for Recycling

Off-site Recycling Services: You contract with a specialized company that picks up your waste solvent, recycles it at their facility, and may return the purified solvent to you or sell it elsewhere. This requires good segregation and labeling.

On-site Recycling (Using a Solvent Reclaim System): You purchase equipment (like the solvent recovery machines we manufacture at ZZKD) to process the waste solvent directly at your facility. This offers more control and potentially greater cost savings long-term.

When is Recycling Most Feasible?

High Volume Waste Streams: The economics work better when dealing with larger quantities of a specific solvent.

Relatively Pure Waste: Solvents contaminated with only non-volatile residues (like oils, pigments, resins) are easiest to purify by simple distillation.

Single Solvent Waste: Mixed solvent waste is much harder and more expensive to separate and recycle effectively. Segregation is key!

Consistent Waste Composition: Predictable waste streams make optimizing the recycling process easier.

Potential Challenges

Purity Requirements: Can the recycled solvent meet the purity specifications needed for your processes? Some applications require very high purity.

Mixed Solvents: As mentioned, separating solvents with close boiling points (azeotropes) can be difficult or impossible with simple distillation.

Regulations: Handling and processing hazardous waste on-site, even for recycling, often involves regulatory compliance and permits.

Initial Investment: On-site systems require capital expenditure for the equipment.

For many labs and industries generating significant amounts of relatively clean, single-solvent waste (like ethanol from extractions, or cleaning solvents), recycling is definitely worth investigating. We've seen many customers successfully implement on-site systems.

How can a solvent reclaim system benefit your operations?

Looking for a practical way to implement solvent recycling on-site? A dedicated solvent reclaim system could be the solution, directly reducing waste and saving money, but how does it fit in?

A solvent reclaim system, essentially an automated distillation unit, benefits operations by allowing on-site recycling of used solvents. This significantly cuts hazardous waste disposal costs, reduces new solvent purchases, promotes sustainability, and provides a convenient, readily available supply of reusable solvent.

This ties directly into what we offer at FBL. Our Solvent Recovery Machines are precisely these kinds of reclaim systems, designed for labs and industries needing efficient, reliable on-site solvent recycling. Investing in such a system brings tangible benefits that we often discuss with potential clients.

Core Principle: Distillation

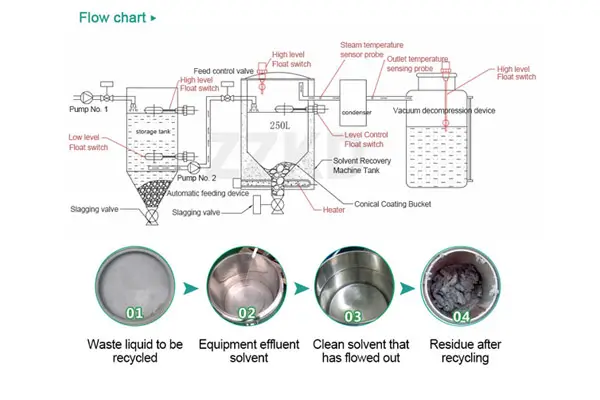

Most solvent reclaim systems work on the principle of distillation:

Heating: The waste solvent mixture is heated in a boiling chamber.

Vaporization: The solvent with the lower boiling point turns into vapor.

Separation: Higher-boiling contaminants (oils, resins, dirt, etc.) remain behind as residue.

Condensation: The solvent vapor travels to a condenser (cooled by air or water) where it turns back into liquid.

Collection: The purified, liquid solvent is collected in a separate container, ready for reuse.

Key Advantages of On-Site Reclaim Systems

| Benefit | Explanation |

| Cost Reduction | Drastically lowers hazardous waste disposal fees (often 90%+ reduction in volume) and cuts spending on new solvent purchases. Payback periods can be surprisingly short. |

| Environmental Sustainability | Reduces hazardous waste generation, conserves resources by reusing solvents, and lowers the carbon footprint associated with solvent production and transport. Supports "green chemistry" initiatives. |

| Convenience & Control | Provides a continuous supply of clean solvent on demand, reducing reliance on external suppliers and disposal schedules. You control the quality and process. |

| Safety | Reduces the amount of hazardous waste stored on-site and minimizes handling and transportation risks associated with off-site disposal. Modern systems have built-in safety features (e.g., temperature limits, pressure relief). |

Considerations When Choosing a System

Capacity: Match the system's processing volume (e.g., liters per batch or per hour) to your waste generation rate.

Solvent Compatibility: Ensure the system's materials (seals, tanks) are compatible with the solvents you intend to recycle.

Automation & Features: Systems range from simple manual units to fully automated ones with programmable cycles, vacuum assist (for higher boiling solvents), and various safety interlocks.

Purity Needs: Simple distillation yields technical-grade solvent. If higher purity is required, multiple distillations or more complex fractional distillation systems might be needed.

Residue Handling: Consider how the concentrated waste residue will be handled and disposed of (it will still be hazardous waste, but much less volume).

We designed our FBL Solvent Recovery Machines with these factors in mind, aiming for robust performance, safety, ease of use, and cost-effectiveness, helping our customers turn a costly waste stream into a valuable resource.

Conclusion

Proper solvent waste disposal involves safe management, but exploring recycling options and potentially investing in an on-site solvent reclaim system offers significant cost savings and environmental benefits for many facilities.