Worried about chemical waste piling up? It is a big problem for safety and our planet. Ignoring it can lead to fines and harm.

Better chemical waste management involves reducing waste at the source, proper segregation, safe disposal, and exploring recycling options like solvent recovery. These steps protect us and the environment effectively.

Understanding and improving how we handle chemical waste is not just a regulatory chore. It is a core part of responsible operation. I want to share some thoughts on this important topic from my years in the industry.

What Is Chemical Waste and Why Is Managing It So Important?

Unsure what counts as chemical waste? This uncertainty can lead to improper handling. This risks accidents and environmental damage if not addressed.

Chemical waste includes unused or leftover chemicals, solvents, and contaminated materials. Managing it well is vital for safety, legal compliance, and protecting our earth for the future.

Based on my experience, chemical waste is a broad term. It covers many things. It is not just about the obviously dangerous liquids. Let's break it down a bit.

Types of Chemical Waste

We see many types of chemical waste. These can include:

Used Solvents: Things like acetone, ethanol, or xylene that have been used for cleaning or in reactions. Many people ask how to dispose of methanol because it's a common solvent.

Old Reagents: Chemicals that are past their expiry date or are no longer needed.

Reactive Wastes: Substances that can explode or react violently under certain conditions.

Toxic Wastes: Materials that are harmful or fatal if ingested or absorbed.

Flammable Wastes: Liquids or solids that can easily catch fire.

Corrosive Wastes: Acids or bases that can eat through containers or skin.

Why Management is Critical

The dangers are real. Improper handling can lead to immediate health issues for people working in the lab or factory. Think about burns, poisoning, or even long-term illnesses. Then, there is the environmental side. Spills or incorrect disposal can contaminate soil and water. This harms wildlife and can get into our food chain. And, of course, there are laws. Businesses face big fines and legal trouble if they do not follow the rules. A company's reputation can also suffer badly. It is simply essential to get this right.

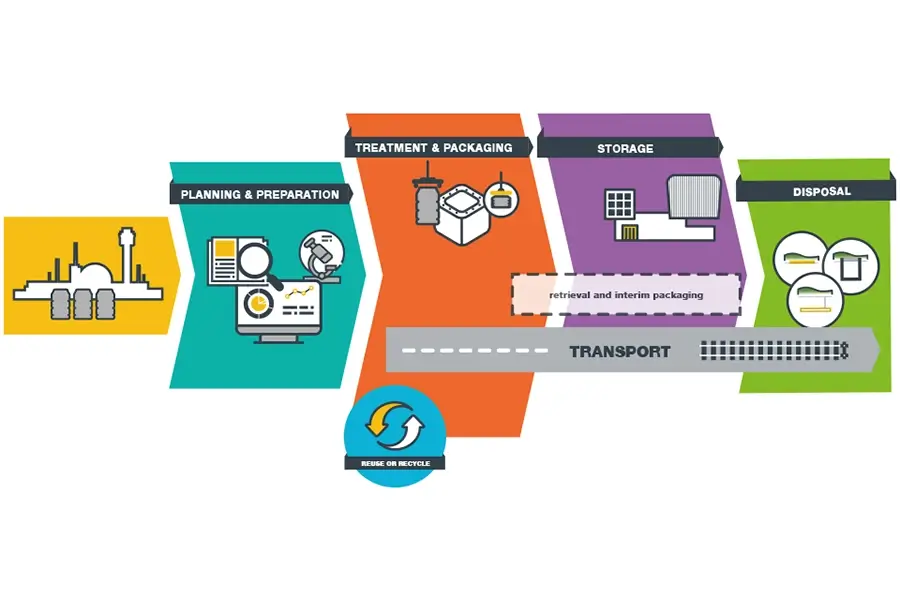

What Are the Common Methods for Chemical Waste Disposal?

Disposing of chemicals feels complicated for many? Choosing the wrong method can be costly. It can also be dangerous for everyone involved if not done right.

Common methods include neutralization for acids and bases, incineration for certain organic compounds, landfilling for treated solid wastes, and recycling for solvents. Always follow local rules strictly.

Choosing the right disposal method is key. It depends a lot on what the chemical is. Here are some common approaches I have seen:

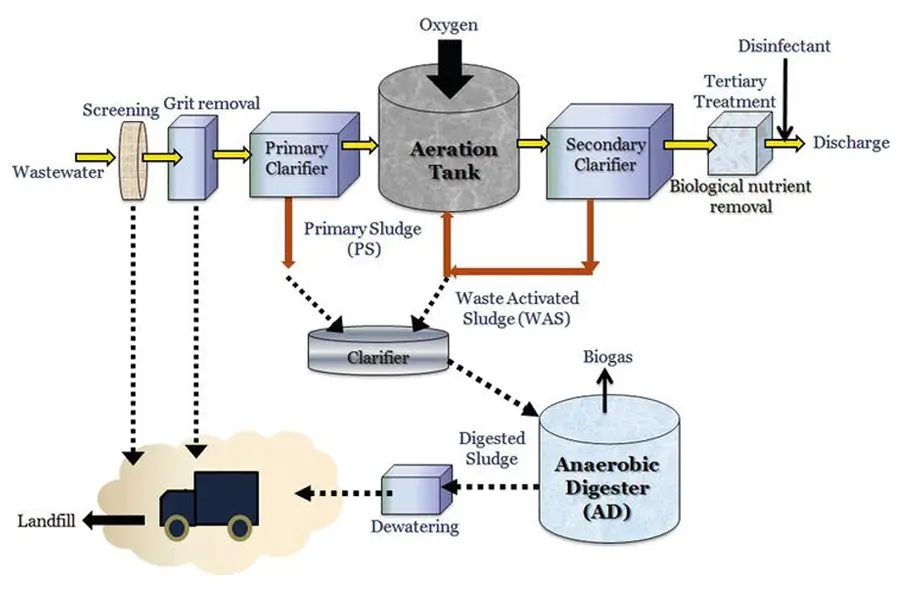

Neutralization

This is often used for acidic or alkaline wastes. We basically adjust the pH to make the waste less harmful. For example, adding a base to an acid. But it is not a solution for everything. The products made during neutralization might still need careful handling.

Incineration

This means burning the waste at very high temperatures. It can destroy many organic solvents and some toxic chemicals. However, it must be done in special incinerators. These incinerators have to control air pollution. The ash left over also needs proper disposal. For instance, when considering how to dispose of isopropyl alcohol on an industrial scale, specialized incineration is one route, but it's costly.

Landfilling

Some treated or inert solid wastes can go to landfills. But these must be special landfills. They are designed to stop harmful stuff from leaking into the ground. This is not the best option for many hazardous chemicals. It's often a last resort.

Chemical Treatment

Sometimes, we can use other chemical reactions. These reactions change the waste to make it less dangerous. This might involve oxidation, reduction, or making solids fall out of a liquid. This needs good chemical knowledge.

The main goal is always to pick a method that works well and is safe for the environment. I always advise my clients that just getting rid of waste is not the whole story. We need to think about the long-term impact. It is about responsible solvent waste management and chemical handling.

How Can Solvent Recovery Systems Help Manage Chemical Waste?

Are solvent costs and disposal fees draining your budget? Relying on third-party disposal can be unpredictable. This also adds to your environmental footprint significantly.

Solvent recovery systems separate usable solvents from waste mixtures. This reduces waste volume, cuts disposal costs, and allows you to reuse valuable solvents in your processes.

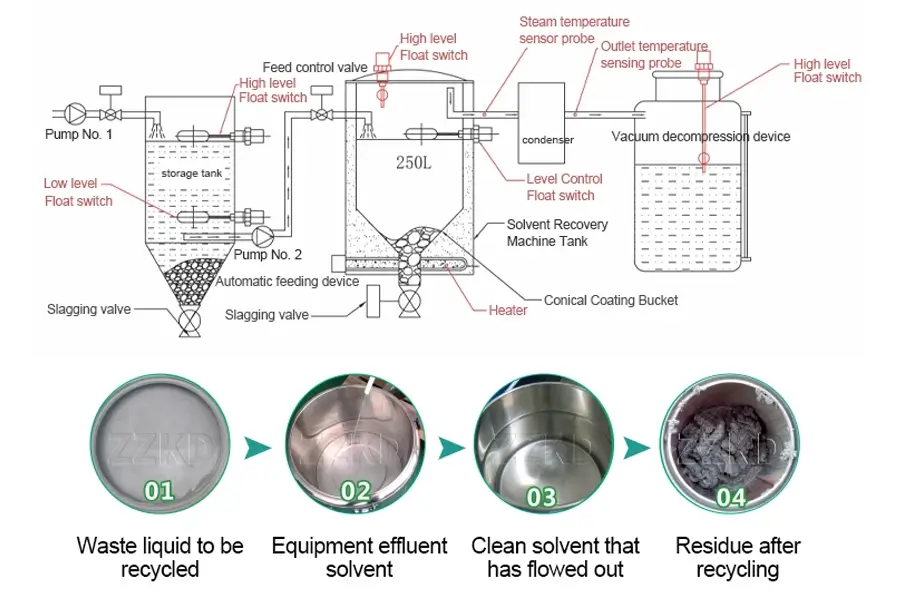

This is where I get really excited because it is a practical solution we offer. A solvent recycling machine can make a huge difference. The basic idea is often simple, usually using distillation.

How It Works

Let me explain the general process. We take the waste solvent mixture. This mixture contains the good solvent and some contaminants.

The system heats this waste mixture.

As it heats, the solvent turns into a vapor. Different solvents turn to vapor at different temperatures.

This solvent vapor is then cooled down. This process is called condensation. It turns the vapor back into a pure liquid solvent.

The contaminants, which usually have higher boiling points or are solids, get left behind.

We can recover many kinds of solvents this way. Alcohols like ethanol and IPA, ketones like acetone, esters, and even some hydrocarbons can be recovered. The purity of the recovered solvent is often very high, good enough to reuse.

Reducing Waste Volume

The biggest impact here is on waste reduction. Instead of having, say, 100 liters of waste solvent to dispose of, you might end up with only 5-10 liters of concentrated contaminants. This drastically cuts down on the amount of hazardous waste. It means less paperwork, lower disposal fees, and less risk. I have seen this make a real difference for businesses. It's a core part of understanding how does a solvent recovery system work to benefit your operations.

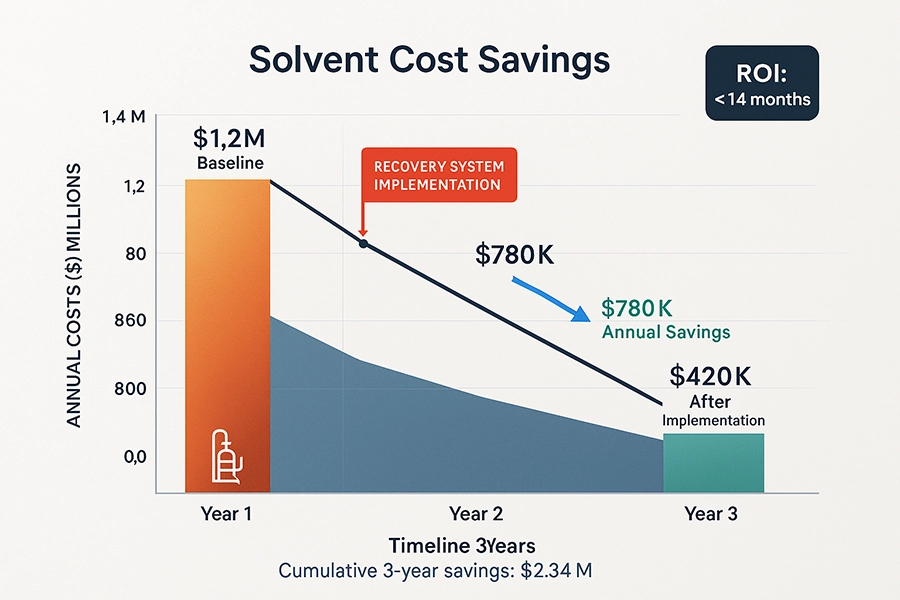

What Are the Benefits of Using a Solvent Recovery System?

Facing rising solvent prices and stricter disposal laws now? These challenges can really impact your bottom line. They also increase your operational risks if not managed well.

Benefits include major cost savings on solvent purchases and disposal, a smaller environmental footprint, and better operational sustainability. It is an investment that pays back quickly.

The advantages of using a solvent recovery system are quite clear and touch on several areas. I have seen these benefits firsthand with many clients.

Economic Benefits

This is often the first thing businesses notice. You buy much less new solvent. Our systems can often recover over 95% of the used solvent. Imagine cutting your solvent purchasing bill by that much! Also, disposal costs drop a lot. You have less waste, so you pay less to get rid of it. The equipment itself is an investment, but the payback period can be very short. I often help customers calculate this, and they are usually surprised how quickly it pays for itself.

Environmental Benefits

This is hugely important. By recovering solvents, we use fewer natural resources. Making new solvents takes energy and raw materials. Reusing them reduces this demand. It also means lower greenhouse gas emissions from solvent production and transport. And, very importantly, it lessens the chance of pollution from improper disposal. It is a big step towards being a greener company.

Operational Benefits

Having a recovery system on-site gives you more control. You have a steady supply of clean solvents when you need them. You are less dependent on outside suppliers and waste disposal companies. This can make your operations smoother. It can also improve safety in the workplace. Storing large amounts of waste solvent can be risky. Reducing that is always good. Plus, being known as an environmentally responsible company is great for your image. Customers and partners appreciate it.

Truly, every liter of solvent you recover is a double win. You save money on buying it new, and you save money on disposing of it. For companies that use a lot of solvents, the savings add up incredibly fast. It is a smart business decision.

Conclusion

Proper chemical waste management is crucial. Solvent recovery systems offer a smart way to reduce waste, save money, and protect our planet for everyone.