Solvent Waste Disposal and Recycling – A Complete Guide

Learn how to manage solvents safely, save costs, and reduce environmental impact in this comprehensive guide.

Proper solvent waste disposal and recycling is crucial for environmental sustainability, workplace safety, and regulatory compliance. In industrial, laboratory, and manufacturing settings, solvents are used daily — from cleaning and degreasing to chemical processing. But improper handling of spent solvents can cause environmental harm, health hazards, and legal issues.

Why Proper Solvent Waste Management Matters

Solvents are often classified as hazardous waste, meaning their disposal is tightly regulated. Improper disposal can lead to groundwater contamination, air pollution, and toxic exposure. According to the U.S. Environmental Protection Agency (EPA), hazardous waste mismanagement has been linked to over 50% of U.S. Superfund site contaminations.

Common Solvent Waste Types

Isopropyl alcohol (IPA) and other alcohol-based solvents (how to dispose of isopropyl alcohol )

Paint thinners and turpentine (paint thinner disposal guide )

Acetone and ketones

Xylene and other aromatic hydrocarbons

Nitric acid and other corrosive chemicals

Environmental & Economic Benefits of Recycling Solvents

Recycling solvents can cut raw material costs by up to 90% and significantly reduce hazardous waste output. Industrial facilities adopting solvent recycler machines often see a return on investment within months due to reduced purchasing and disposal fees.

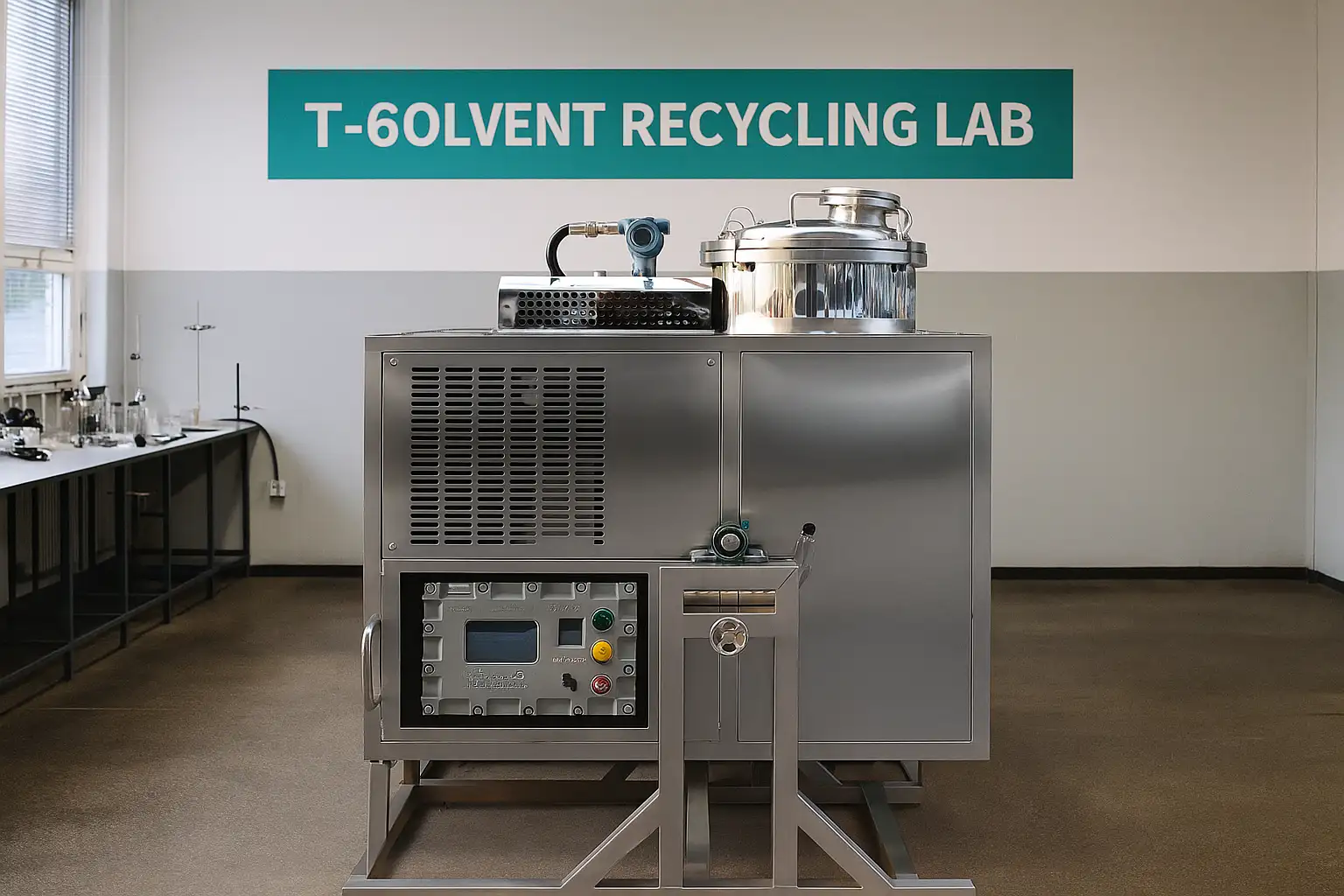

How Solvent Recycler Machines Work

Solvent recycler machines use distillation to separate contaminants from the solvent. The process involves heating the contaminated solvent until it vaporizes, then cooling it back into a liquid. This recovered liquid can be reused, while contaminants are collected for safe disposal.

Question:

What happens if solvent waste is poured directly down the drain?

Answer:

This can cause severe water pollution, damage sewage systems, and violate environmental regulations. Solvents can kill beneficial bacteria in wastewater treatment plants, leading to untreated waste being discharged into natural water bodies.

Best Practices for Solvent Waste Disposal and Recycling

Segregate solvent waste from non-hazardous waste.

Use clearly labeled, compatible containers with tight-sealing lids.

Store waste in a cool, well-ventilated area away from ignition sources.

Utilize solvent recovery systems to reclaim usable product.

Work with certified hazardous waste disposal companies for remaining residues.

Question:

Is it safe to recycle all types of solvents on-site?

Answer:

Most organic solvents, like IPA, acetone, and xylene, can be safely recycled using commercial machines. However, highly reactive or explosive chemicals should be handled by specialized facilities.

Case Study: Cost Savings by Implementing Recycling

One electronics manufacturing company reported that switching to an in-house solvent recycling system reduced their solvent purchase costs by 75% within six months. They also cut their hazardous waste disposal fees by half.

$15,000/month solvent purchases

$8,000/month waste disposal

Annual costs: $276,000

$3,750/month solvent purchases

$4,000/month waste disposal

Annual costs: $93,000

Question:

Can recycled solvents match the quality of new solvents?

Answer:

Yes, when processed with high-quality solvent recycler machines, recycled solvents often achieve 95–99% purity, making them suitable for most industrial applications.

Conclusion

Solvent waste disposal and recycling is not just a legal requirement; it's a strategic move for sustainability, cost reduction, and workplace safety. Modern solvent recycling equipment makes it easier than ever to recover valuable materials while protecting the environment.