Solvent Regeneration Technology

Achieving Sustainable Industrial Processes Through Advanced Solvent Recovery Systems

Solvent Regenerator: The Future of Sustainable Chemical Processing

Reducing Waste, Cutting Costs, and Building a Greener Future

In industries ranging from automotive to pharmaceuticals, solvents play a critical role in cleaning, extraction, and manufacturing processes. But disposing of used solvents is both costly and environmentally harmful. This is where a solvent regenerator—also known as a solvent recycling machine—comes into play.

What is a Solvent Regenerator?

A solvent regenerator is a specialized piece of equipment designed to recover and purify used solvents so they can be reused. This process reduces waste, saves money, and minimizes environmental impact. The technology typically uses distillation, filtration, or advanced membrane separation to remove contaminants from spent solvents.

How Does the Process Work?

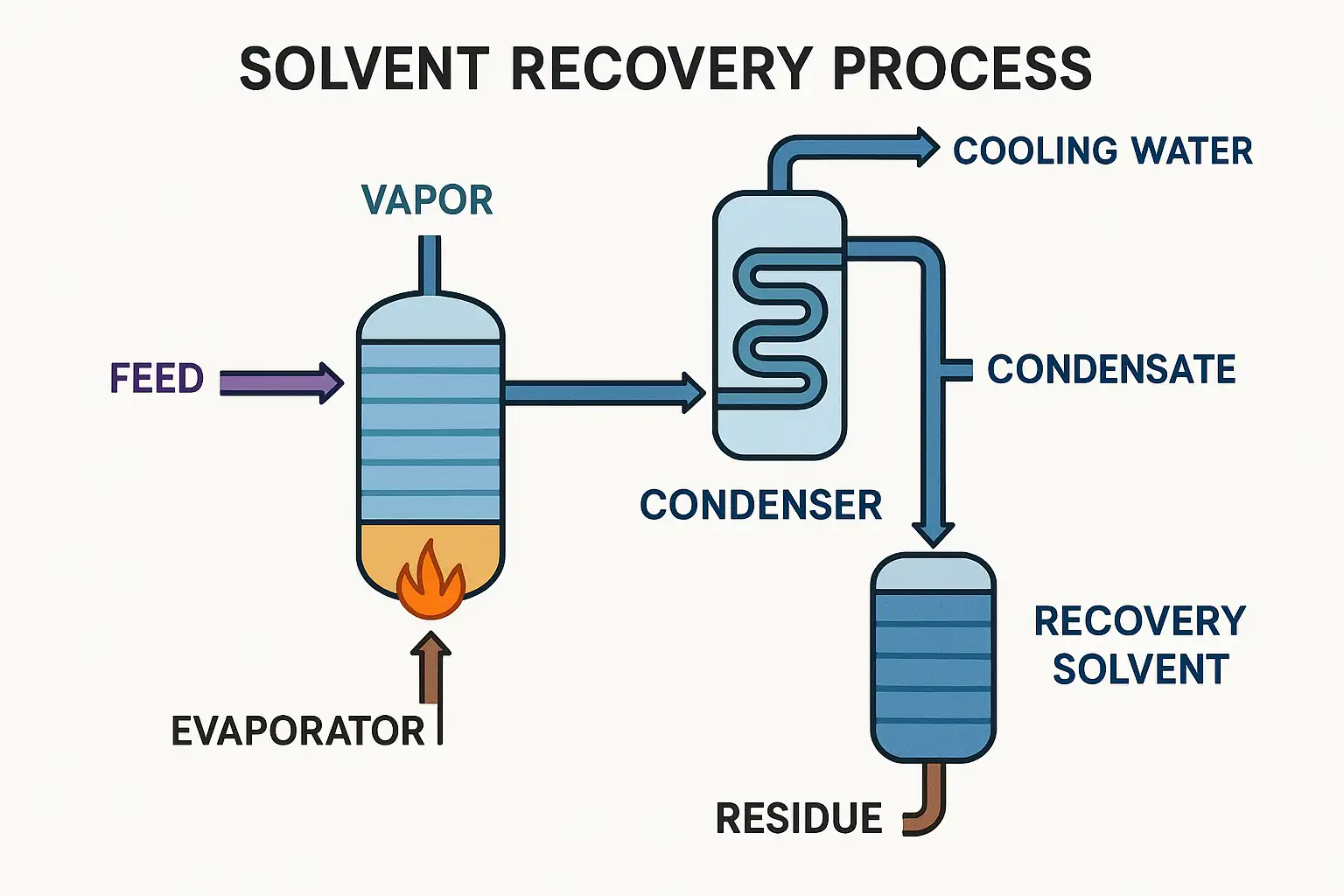

The regeneration process typically involves several stages for the most effective purification:

Collection & Pre-Filtration

Contaminated solvent is collected and passed through a preliminary filter to remove large particulates and debris.

Heating & Distillation

The solvent is heated in a distillation chamber. As it vaporizes, impurities are left behind due to differences in boiling points.

Vapor Condensation

The purified vapor is cooled and condensed back into liquid form, resulting in clean solvent ready for reuse.

Post-Filtration (Optional)

For enhanced purity, the regenerated solvent may pass through specialized filters or molecular sieves.

| Solvent Type | Recovery Rate | Typical Purity | Distillation Temp | Reuse Applications |

|---|---|---|---|---|

| Acetone | 90-95% | 98-99.9% | 56°C | Cleaning, degreasing |

| Isopropyl Alcohol | 92-97% | 97-99.5% | 82°C | Disinfecting, electronics |

| Xylene | 85-90% | 95-98% | 138°C | Paint, adhesives |

| Toluene | 88-93% | 96-99% | 110°C | Chemical synthesis |

| Methanol | 90-94% | 97-99.5% | 65°C | Biodiesel, pharma |

Question: Can all solvents be regenerated using the same equipment?

Answer: Not exactly. While many common solvents such as acetone, isopropyl alcohol, and xylene can be regenerated, the specific equipment configuration may vary depending on boiling points, chemical stability, and contamination type. For example, a acetone recycling machine may have different temperature controls compared to a unit designed for methanol.

Why is Solvent Regeneration Important?

According to the U.S. Environmental Protection Agency (EPA), industrial solvent waste accounts for a significant portion of hazardous waste generated annually. By regenerating solvents, companies can reduce hazardous waste output by up to 80%.

Furthermore, MIT research suggests that automation and AI could replace 30% of jobs by 2030, making efficiency and sustainability even more crucial for competitiveness. Solvent regenerators represent both a cost-saving and eco-friendly adaptation in this changing industrial landscape.

Economic Benefits

Reduces procurement costs 50-90% and avoids disposal fees.

Environmental Impact

Minimizes chemical waste and reduces carbon footprint.

Resource Conservation

Reduces demand for virgin solvents by up to 95%.

Safety

Reduces hazardous waste storage and transport risks.

Economic Benefits

Purchasing new solvents repeatedly is expensive. Regenerating solvents can cut procurement costs by 50–90%, depending on the solvent type and usage volume. Additionally, companies save on disposal fees and avoid potential fines for improper waste handling.

Question: Is it safe to dispose of solvents like isopropyl alcohol down the drain instead of regenerating them?

Answer: No, it is unsafe and often illegal to pour solvents down the drain. They can contaminate water supplies and harm aquatic life. For safe disposal guidelines, see our guide on how to dispose of isopropyl alcohol. Regeneration is a far safer and more sustainable option.

Environmental Impact

Solvent regeneration reduces the demand for virgin solvent production, which often involves energy-intensive processes and petrochemical resources. It also lowers greenhouse gas emissions associated with manufacturing and transportation.

Did you know? The solvent recycling industry prevents over 2 million tons of hazardous waste from entering landfills and waterways every year.

Choosing the Right Solvent Regenerator

When selecting a solvent regenerator, consider the following key factors:

Solvent Compatibility

Ensure the system works with the specific solvents used in your processes.

Processing Capacity

Match the machine capacity with your daily solvent consumption volume.

Automation Level

Determine if you need manual, semi-automatic, or fully automatic operation.

Safety Features

Check for built-in safety interlocks, pressure relief, and monitoring systems.

For example, a solvent recovery system with built-in safety interlocks and temperature monitoring ensures both quality output and operator protection.

Question: How quickly can a company see ROI after investing in a solvent recycling machine?

Answer: Many companies report a return on investment within 6–18 months, depending on solvent usage volume and local disposal costs. High-consumption industries like automotive painting and pharmaceutical manufacturing tend to see faster payback periods.

Conclusion

Solvent regenerators are more than just machines—they are a gateway to sustainable industrial practices. By integrating solvent recovery into operations, companies can achieve significant cost savings while demonstrating environmental responsibility and regulatory compliance.

Professional Advice: For more details on equipment options, visit our solvent recycling machine page or learn about the solvent recycling system best suited to your needs. Our engineering team can provide a free consultation and ROI analysis for your specific requirements.