Used Solvent Recovery Machine: When It Makes Sense and What to Look For

Used solvent recovery machines can cut solvent purchases by up to 90% and reduce hazardous waste, but only if the right equipment is chosen and maintained. This guide explains the key points in plain English.

Many factories, paint shops, printing houses and labs still treat used solvent as a one‑way ticket: buy it, use it once, then pay again to get it hauled away. A used solvent recovery machine can break this cycle, but the purchase decision is often delayed because the technology sounds complicated, or the cost looks high on paper.

From an engineering and SEO standpoint, the core question behind “used solvent recovery machine” is actually simple: can existing solvent waste be turned back into usable solvent safely, reliably and cheaper than buying new? Below, this question is broken down into specific, practical points buyers usually care about.

1. What Is a Used Solvent Recovery Machine?

A solvent recovery machine is essentially a controlled distillation unit. It heats dirty solvent, turns it into vapor, and then condenses that vapor back into a clean liquid. A used solvent recovery machine simply means a pre‑owned unit that has already been operating in another facility, then refurbished or resold.

Typical applications include acetone, isopropyl alcohol, xylene, paint thinner, cleaning solvents and many other organic solvents. These systems are closely related to the equipment described inhow a solvent recovery system works.

Why do some facilities specifically look for a used solvent recovery machine instead of buying a new unit?

There are two main reasons noticed in practice: first, to reduce upfront capital expenditure, especially when management is not yet fully convinced about ROI; second, to test solvent recycling in one production line before rolling it out across the entire plant. A well‑maintained used unit can provide real‑world performance data at a lower entry cost.

2. How Does a Solvent Recovery Machine Actually Work?

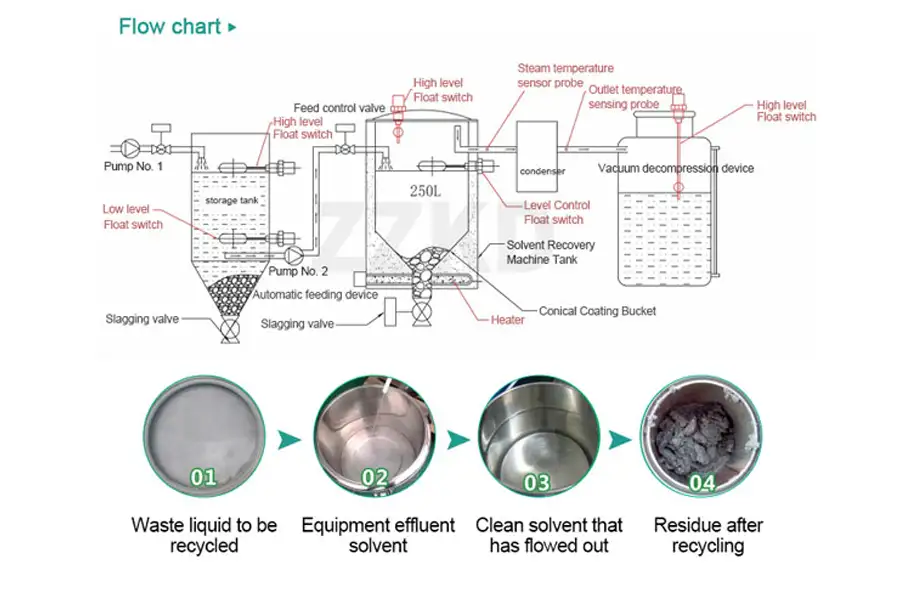

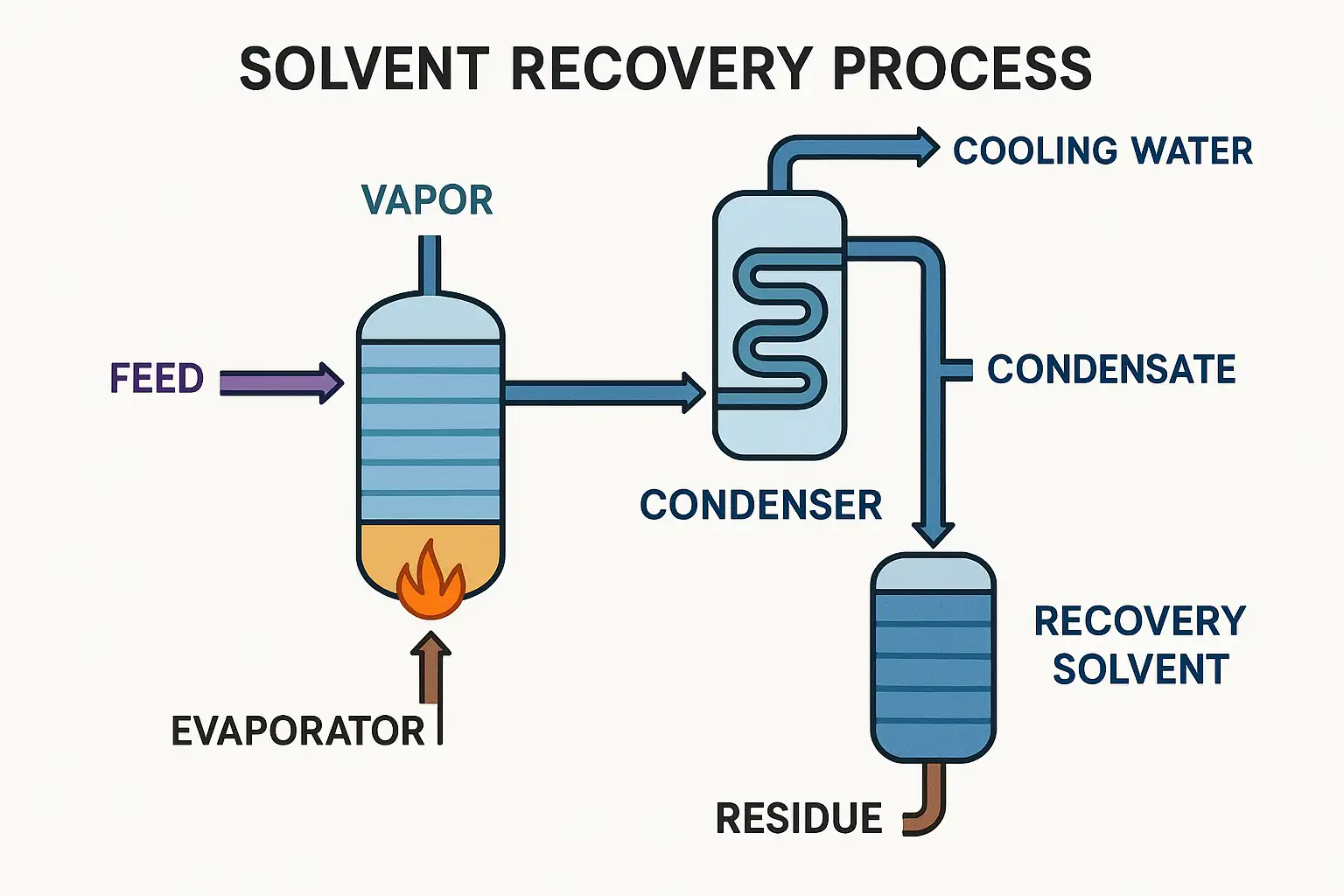

The internal principle is similar whether the unit is new or used:

Heating: Contaminated solvent is poured or pumped into a stainless‑steel boiling tank.

Evaporation: The solvent is heated until it vaporizes, leaving paints, oils, inks, resins and other non‑volatile solids behind.

Condensation: Vapors pass through a cooled condenser where they turn back into liquid.

Collection: The recovered solvent flows into a clean container, usually achieving around 90–95% recovery under proper operating conditions.

For a more general overview of solvent recovery, it can be helpful to readwhat solvent recovery is and why it matters, then come back to the specific case of used equipment.

3. Typical Capacities and Key Parameters

Regardless of new or used condition, technical parameters strongly influence whether a machine fits an application. Below are representative specifications from a family of explosion‑proof solvent recovery machines often found on the used market:

| Model | Feed Capacity (L) | Heating Power (kW) | Temperature Range (°C) | Typical Treatment Time (min) | Recovery (%) | Approx. Size (mm) |

|---|---|---|---|---|---|---|

| T‑20Ex | 20 | 2 | RT–200 | ≈120 | Up to 95% | 860 × 760 × 1190 |

| T‑60Ex | 60 | 4 | RT–200 | ≈150 | Up to 95% | 1160 × 870 × 1260 |

| T‑80Ex | 80 | 5 | RT–200 | ≈180 | Up to 95% | 1180 × 850 × 1290 |

| T‑125Ex | 125 | 6 | RT–200 | ≈210 | Up to 95% | 1250 × 920 × 1450 |

| T‑250Ex | 250 | 16 | RT–200 | ≈240 | Up to 95% | 2600 × 1200 × 1950 |

| T‑400Ex | 400 | 32 | RT–200 | ≈270 | Up to 95% | 1990 × 1850 × 2090 |

The exact models on the used market will vary, but these figures illustrate a common pattern: higher capacity means larger footprint, higher heating power and longer (but more efficient) batch times.

Key parameters to evaluate on a used unit

Capacity (L per batch): Must match daily waste solvent volumes.

Heating power and temperature range: Determines which solvents can be processed and how quickly.

Recovery rate (%): Many industrial units achieve around 95% under proper conditions.

Explosion‑proof rating (Ex): Critical for flammable solvents such as acetone, IPA or xylene.

Physical size and weight: Important for installation space and floor loading.

Is a 20 L machine enough for a small workshop that generates about 40–50 L of dirty solvent per day?

In most cases, yes, if two batches per day are acceptable and there is one operator who can start and stop cycles. However, if production runs 2–3 shifts or solvent waste fluctuates, it is usually safer to choose a 60 L or 80 L machine so that peaks can be absorbed without overtime or delays.

4. When Does a Used Solvent Recovery Machine Pay for Itself?

Payback is one of the first questions asked by plant managers and owners. A realistic, simplified way to calculate it is:

Payback period ≈ (Cost of machine) ÷ (Savings per year)

Typical savings come from three sources:

Reduced purchase of fresh solvent.

Reduced hazardous waste disposal fees.

Less storage and transport cost for solvent waste.

As a reference, a 2022 analysis by a European industrial trade association found that facilities using on‑site solvent recovery cut overall solvent‑related operating costs by an average of 45–65%, with a typical payback period of 12–24 months for medium‑size installations.

For a used machine, the investment is obviously lower, so payback can be even faster, provided that:

The machine still achieves close to its original recovery rate.

Maintenance and spare parts are available.

Energy consumption has not increased due to damaged insulation or worn components.

5. Main Benefits of Installing a Used Solvent Recovery Machine

In practice, companies usually care about three main outcomes: cost, compliance and sustainability.

5.1 Cost savings

Solvent purchase reduction: If recovery reaches around 95%, 1000 L of dirty solvent can yield about 950 L of clean solvent, drastically reducing new purchases.

Waste disposal reduction: Instead of paying to remove full drums of liquid solvent, only solid residues and concentrated contaminants need disposal.

Used vs new pricing: A used solvent recovery machine can often cost 30–50% less than a new unit, while providing 70–90% of the lifetime performance if properly refurbished.

5.2 Environmental and compliance benefits

Lower hazardous waste volume: Fewer drums shipped off‑site.

Reduced VOC emissions: Closed systems help minimize evaporation during handling.

Better alignment with regulations: Many regions encourage or partially subsidize on‑site solvent recycling as part of circular‑economy policy.

5.3 Operational benefits

Stable solvent quality: Recovered solvent can be consistent enough for many applications, especially washing and cleaning processes.

Less dependence on external disposal contractors: More control over schedule and cost.

Easier handling of solvent waste streams: On‑site recovery is often combined with better segregation and labeling of waste, which improves overall safety.

6. Specific Risks and Checks for Used Equipment

Unlike a new unit, a used solvent recovery machine has an unknown history. This is where careful inspection matters more than the brochure.

6.1 Safety and explosion‑proof compliance

Confirm that explosion‑proof labels (for motors, control boxes, heaters) are still readable and valid.

Check whether any electrical modifications were made on‑site by the previous owner.

Inspect grounding points, earthing continuity and the condition of cables and glands.

6.2 Mechanical condition

Look for corrosion or pitting in the boiling tank and condenser.

Check seals, gaskets and door locking mechanisms for wear or deformation.

Verify that the condenser is not partially clogged; poor cooling reduces recovery rate and increases energy use.

6.3 Documentation and service support

Request operation and maintenance manuals, wiring diagrams and spare parts lists.

Confirm whether the original manufacturer or a qualified service partner is still available.

Ask for previous maintenance logs or repair records, if possible.

Is it safer to buy a used solvent recovery machine directly from the original manufacturer or from a general reseller?

Experience shows that buying from the original manufacturer or an authorized refurbisher is usually safer. They understand the design limits, can replace critical components with original parts, and are more willing to provide warranty on refurbished units. A general reseller may offer a lower price, but the hidden costs of bringing the unit up to safe standard can easily exceed the initial savings.

7. Matching a Used Machine to the Actual Process

Even if a used unit is in good condition, it must fit the process. Common questions include:

Which solvents are being used? For example, acetone, isopropyl alcohol, xylene, toluene, mixed paint thinners, etc.

What contaminants are present? Paint, resin, oil, pigment, water or acids.

How many liters of waste are generated per day or per week?

What is the required purity level for the recovered solvent?

For pure solvent streams like acetone or ethanol, off‑the‑shelf configurations such as anacetone recycling machineare often suitable, even in used form. For more complex mixtures, it may be necessary to test a sample first or adjust operating temperature and batch time.

8. Summary and Practical Takeaways

A used solvent recovery machine is not just a piece of second‑hand equipment; it is a potential lever for cost reduction and environmental responsibility, provided that the unit is carefully selected, inspected and matched to the process.

On‑site recovery often cuts solvent purchases by 60–80% and hazardous waste by 50–70%, with typical payback in 1–2 years.

Used equipment lowers upfront cost but increases the need for careful checks on safety, explosion‑proof compliance and mechanical condition.

Capacity, heating power, recovery rate and solvent type compatibility are the main technical parameters to match.

Buying refurbished units from the original manufacturer or an authorized partner significantly reduces risk.

For operations that are still paying to dispose large volumes of solvent waste or struggling with questions like “how to dispose of solvent waste safely”, on‑site recycling is usually worth serious consideration. Whether the solution is a brand‑new unit or a carefully refurbished used solvent recovery machine will depend on budget, risk tolerance and long‑term production plans, but the underlying economics and environmental logic are increasingly difficult to ignore.