Solvent Recovery Plant: A Practical Guide to Cutting Solvent Cost and Waste

A solvent recovery plant turns used solvents into usable product again. This article explains, in simple language, how solvent recycler machines work, what performance to expect, and when a solvent recycling system makes financial sense.

A solvent recovery plant is a combination of solvent recycler machines, safety systems and operating procedures designed to reclaim used solvents instead of sending them out as hazardous waste. For factories, paint shops, laboratories and print houses, solvent recovery has moved from “nice to have” to “must have” as solvent prices, disposal costs and environmental regulations continue to rise.

The core idea is simple: instead of paying to buy fresh solvent and paying again to dispose of dirty solvent, the same liquid is reused many times after distillation. According to a review by the European Environment Agency, closed-loop solvent recovery can reduce hazardous solvent waste volumes by over 50% in sectors like metal finishing and coating when correctly implemented.

What Is a Solvent Recovery Plant?

In practical terms, a solvent recovery plant is a dedicated area or skid that includes:

One or more solvent recycler machines (also called solvent distillers or solvent recovery units).

Storage tanks for dirty solvent, recovered clean solvent and sludge.

Explosion-proof electrical and ventilation systems where required.

Drums, pumps and piping for safe transfer.

Standard operating procedures and safety controls.

The heart of the plant is the recycler machine itself. If needed, a detailed explanation of how a fullsolvent recovery systemfits into a factory can be found in the existing technical blog, but here the focus stays on the essentials that matter for decision-making.

No. Modern compact units make solvent recovery feasible even for small and mid-size workshops. Feed capacities from 20 L per batch upward already provide a payback for many paint, printing and automotive repair shops, if solvent consumption and disposal fees are above a modest threshold.

How Does a Solvent Recovery Plant Work in Simple Steps?

1. Collection of used solvent

Dirty solvent from washing, cleaning or process steps is collected in drums or tanks. Typical examples include isopropyl alcohol (IPA), acetone, xylene, lacquer thinner and mixed organic solvent waste. Many facilities first learn safe handling from resources such assolvent waste recycling and disposal guides, then move to recovery once volumes grow.

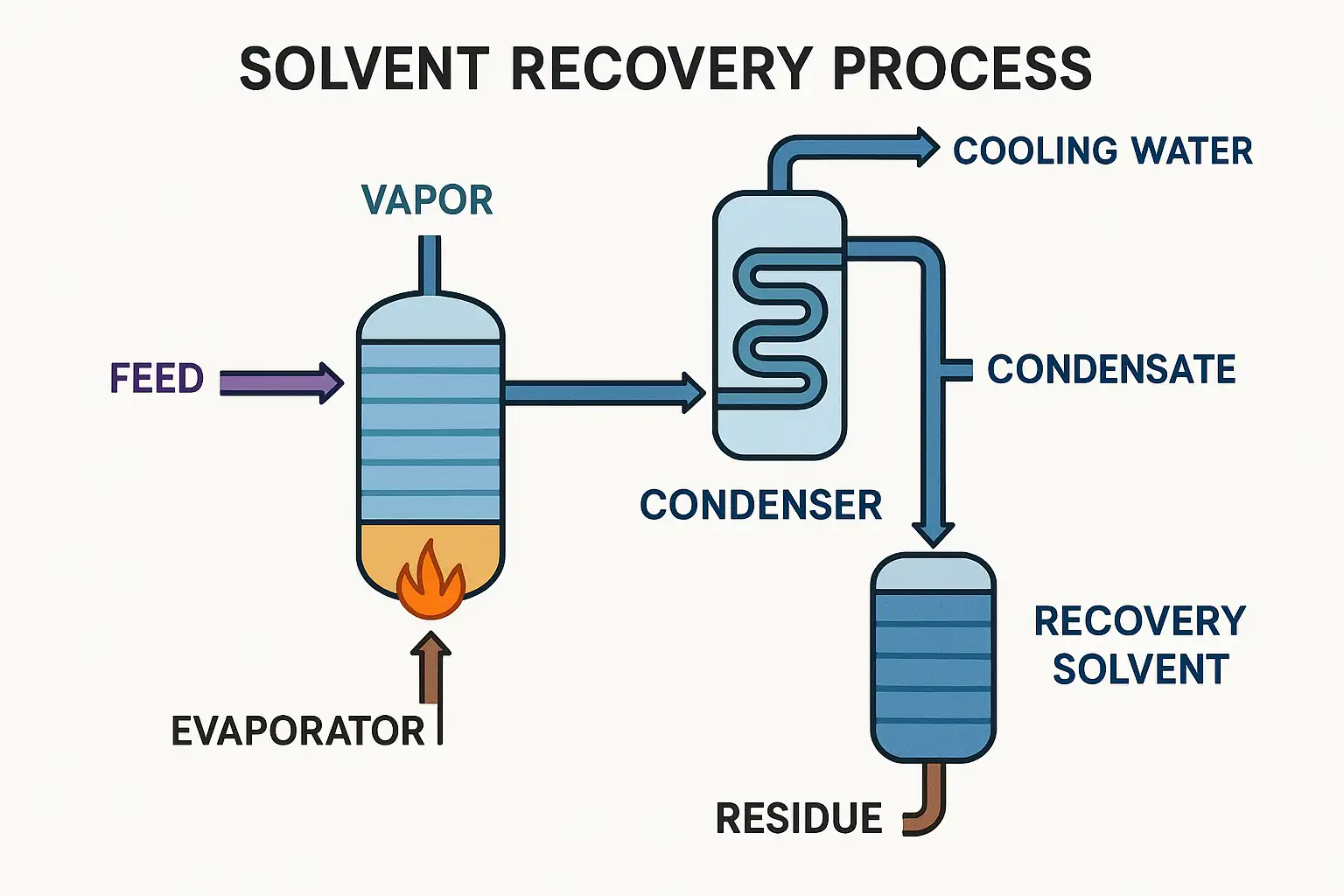

2. Distillation in the solvent recycler machine

The dirty solvent is pumped or poured into the distillation chamber. The machine heats the mixture so that the solvent evaporates but heavier contaminants (resins, paints, oils, pigments, salts) remain.

Vapors are then condensed back into liquid in a cooled section and collected as clean solvent. Most industrial units use a temperature range from room temperature (RT) up to around 200 °C, which is enough for many common organic solvents.

3. Handling of sludge

After each batch, a small amount of concentrated sludge (paint solids, oils, resins) remains in the tank or disposable bag. This residue is much smaller in volume than the original waste stream and is sent for hazardous waste treatment.

4. Reuse of recovered solvent

The recovered solvent is usually clear and suitable for reuse in cleaning or even in production steps, depending on purity demands. In many coating and printing applications, recovered solvent can replace60–90% of virgin solvent without affecting quality.

Why Invest in a Solvent Recovery Plant?

1. Direct cost savings

The most common driver is cost. A well-sized solvent recycling system reduces both sides of the cost equation:

Less purchasing of fresh solvent.

Less paying for hazardous waste disposal.

A study published by the U.S. Environmental Protection Agency on solvent management in small manufacturers reported that on-site solvent recovery projects often achieve payback within 6–24 monthswhen monthly waste volumes exceed 1 ton.

2. Compliance and risk reduction

Environmental and safety regulations around solvent waste, VOC emissions and flammable liquids continue to tighten. A solvent recovery plant:

Reduces hazardous waste volume and number of waste shipments.

Lowers risk of spills during storage and transport.

Makes it easier to prove responsible handling to regulators and customers.

3. Sustainability and corporate image

Many customers now audit suppliers on sustainability metrics. Internal recycling is a visible, concrete action. According to a survey by the World Economic Forum and Boston Consulting Group, more than70% of industrial buyers said that environmental performance is now a “medium” or “high” priority when choosing suppliers, especially in automotive, electronics and consumer goods.

Not always, but in many cleaning and flushing applications it is more than sufficient. For high-purity applications (for example, electronics or pharmaceutical production), recovered solvent can be used for pre-cleaning, while virgin solvent is reserved for critical final steps. Careful control of distillation temperature and cut points helps achieve repeatable quality.

Solvent Recovery Plant Equipment: Typical Batch Sizes and Performance

Below is an example range of explosion-proof solvent recycler machines frequently used as the core of a solvent recovery plant. All models are designed for up to around 95% recovery per batch under suitable conditions.

| Model | Feed capacity (L) | Heating power (kW) | Recovery (%) | Machine weight (kg) | Machine size (mm) |

|---|---|---|---|---|---|

| T-20Ex | 20 | 2 | 95 | 153 | 860 × 760 × 1190 |

| T-60Ex | 60 | 4 | 95 | 170 | 1160 × 870 × 1260 |

| T-80Ex | 80 | 5 | 95 | 200 | 1180 × 850 × 1290 |

| T-125Ex | 125 | 6 | 95 | 280 | 1250 × 920 × 1450 |

| T-250Ex | 250 | 16 | 95 | 520 | 2600 × 1200 × 1950 |

| T-400Ex | 400 | 32 | 95 | 1200 | 1990 × 1850 × 2090 |

How to Decide If a Solvent Recovery Plant Is Worth It

When planning a solvent recovery project, the following points usually decide whether it makes economic sense:

1. Daily or monthly solvent usage

As a very rough rule of thumb, solvent recovery becomes attractive when total dirty solvent volume is above 300–500 L per month. Below that, the savings might not justify the equipment and maintenance; above that, payback is often rapid.

2. Solvent type and contamination

Distillation works best when the solvent has a significantly lower boiling point than the main contaminants. Solvents like acetone, ethanol, isopropyl alcohol, toluene and xylene are typical candidates. If a mixing of many solvents is present, a more detailed analysis may be required.

3. Current disposal cost

If hazardous solvent waste disposal costs are high in the local region, on-site recovery quickly becomes attractive. Many facilities pay disposal fees plus transport and handling charges, which a solvent recovery plant helps avoid.

For many users with steady solvent consumption, payback often falls between 1 and 3 years. High solvent prices and high hazardous waste fees shorten the payback period; low prices and low volumes extend it. A simple spreadsheet calculation using current purchase and disposal invoices usually gives a clear answer.

4. Space, power and staffing

Modern units are compact. For example, a 20 L batch machine may occupy less than 1 m² of floor space, while a 400 L unit is still small compared with many production machines. Power requirements range from about 2 kW to 32 kW in the example models shown earlier, and units are often operated by existing staff after short training.

Safety and Integration of a Solvent Recovery Plant

Because many solvents are flammable, safety is central in solvent recovery plant design. Explosion-proof (Ex) models, proper ventilation, grounding and temperature controls are standard features in industrial systems.

Key safety practices

Place the plant in a well-ventilated area, away from ignition sources.

Use approved containers and pumps for transferring solvents.

Follow local codes for electrical classification and explosion protection.

Train operators on emergency shutdown and spill response.

Integration into existing workflows is usually straightforward: dirty solvent collection points are connected by drum, tote or pipeline to the recovery unit. Clean solvent storage then feeds back into cleaning lines, parts washers or production lines as appropriate.

From Solvent Waste Disposal to Closed-Loop Recovery

Many companies first approach solvents from the waste side: how to dispose of isopropyl alcohol, acetone, paint thinner or xylene safely and legally. Guidance on topics such ashow to dispose of isopropyl alcoholor nitric acid is a natural first step.

Once the scale of solvent waste is understood, a solvent recovery plant is the logical next step. Instead of only asking “how to dispose of solvent waste,” the question becomes “how to minimize waste by recovering reusable solvent on-site.” For many facilities, this transition significantly improves both the bottom line and ESG performance.