Solvent Waste Recovery Services: Turning Hazardous Solvent Waste into Reusable Value

Solvent waste recovery services help convert dirty, used solvents into clean, reusable products. This reduces hazardous waste, cuts purchase costs, and supports compliance with tightening environmental rules.

Understand what solvent waste recovery services actually do.

See how modern solvent recycler machines work in plain language.

Learn what savings and environmental benefits are realistic.

1. What Are Solvent Waste Recovery Services?

Solvent waste recovery services are solutions that help businesses recycle their used solvents instead of treating them purely as hazardous waste. They usually combine three elements:

On‑site solvent recycler machines (distillation units).

Professional setup, training, and maintenance.

Support for waste classification, documentation, and compliance.

In simple terms, dirty solvent is heated in a controlled way. The clean solvent evaporates, is condensed, and collected for reuse. Paints, resins, oils and other contaminants stay behind as a concentrated residue that is easier and cheaper to dispose of.

According to a report by the European Environment Agency, hazardous waste generation in the EU increased by around 20% between 2010 and 2020, with chemical waste as a major contributor. This trend pushes regulators and companies toward more efficient solvent recovery instead of simple disposal.

For businesses that use isopropyl alcohol, acetone, xylene, methanol, paint thinners, or other organic solvents, this shift is already visible in daily operations. Regulations are stricter, disposal options are more limited, and costs keep rising.

2. How Do Solvent Recycler Machines Work?

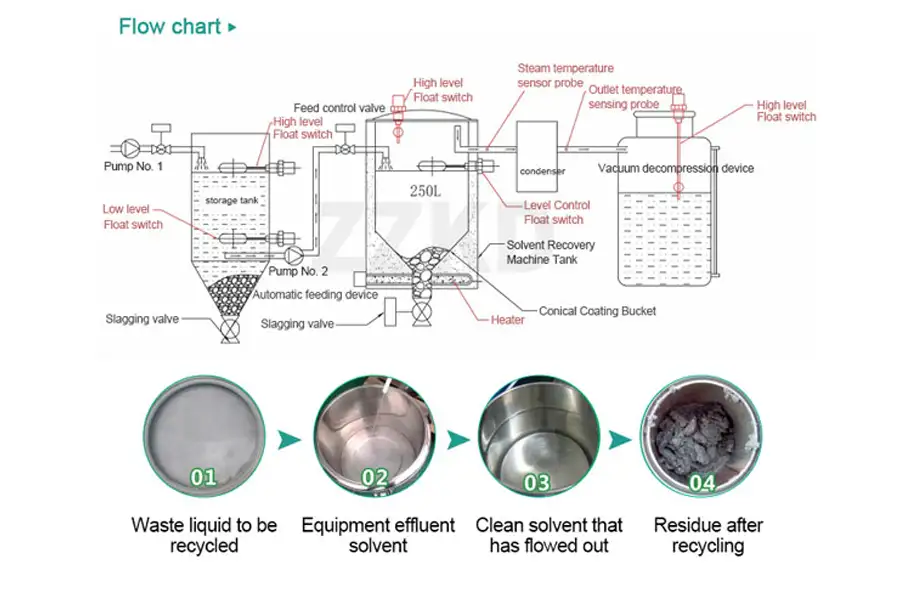

Most modern solvent waste recovery services are built around a solvent recycler machine. Technically, these are small distillation units designed for industrial safety and repeatable performance. One common process looks like this:

Feeding: Used solvent is poured or pumped into a stainless-steel tank (the “boiler”).

Heating: The machine heats the mixture. Solvent boils and turns into vapor; heavier contaminants remain liquid or solid.

Condensing: Vapors pass through a condenser, cool down, and become clean liquid solvent.

Collection: Recovered solvent flows into a clean drum or container.

Residue removal: Concentrated waste left in the boiler is collected for proper hazardous waste disposal.

For a more detailed explanation of the basic process and system components, see the guide onhow a solvent recovery system works.

2.1 Example Capacities and Performance

Below is a simplified example of typical explosion‑proof solvent recycler models that might be used in solvent waste recovery services. Values are illustrative but reflect realistic industrial ranges.

| Model | Feed Capacity (L) | Heating Power (kW) | Temperature Range (°C) | Typical Treatment Time (min) | Recovery (%) | Approx. Size (mm) |

|---|---|---|---|---|---|---|

| T‑20Ex | 20 | 2 | RT–200 | ≈120 | Up to 95% | 860 × 760 × 1190 |

| T‑60Ex | 60 | 4 | RT–200 | ≈150 | Up to 95% | 1160 × 870 × 1260 |

| T‑80Ex | 80 | 5 | RT–200 | ≈180 | Up to 95% | 1180 × 850 × 1290 |

| T‑125Ex | 125 | 6 | RT–200 | ≈210 | Up to 95% | 1250 × 920 × 1450 |

| T‑250Ex | 250 | 16 | RT–200 | ≈240 | Up to 95% | 2600 × 1200 × 1950 |

| T‑400Ex | 400 | 32 | RT–200 | ≈270 | Up to 95% | 1990 × 1850 × 2090 |

A 90–95% recovery rate is realistic in many real‑world cases, as long as the waste stream is reasonably consistent and not overloaded with non‑volatile contaminants. In practice, recovery might be slightly lower for very dirty or mixed wastes, but even 80–85% recovery usually delivers significant purchase and disposal savings.

3. What Problems Do Solvent Waste Recovery Services Actually Solve?

Businesses do not invest in solvent waste recovery services just to have another machine on the shop floor. They invest because several practical problems are becoming more painful:

High solvent purchase costs – especially for acetone, isopropyl alcohol, ethanol and specialty solvents.

Rising hazardous waste disposal fees – transport, treatment and incineration costs continue to grow.

Storage and safety risks – multiple drums of waste solvent mean more flammable material on site.

Complex compliance – stricter rules for waste codes, documentation and traceability.

According to the OECD, global chemical production is expected to roughly double between 2017 and 2030, intensifying pressure on waste infrastructure and regulations worldwide. For companies that rely on solvents in their process, this translates directly into higher risk and higher recurring costs if all spent solvent is simply treated as waste.

3.1 Cost Scenario: From Waste to Savings

Consider a small to medium factory that uses 500 liters of solvent per week for cleaning or production:

Fresh solvent cost: assume 2.5 USD per liter.

Hazardous waste disposal: assume 0.8–1.2 USD per liter.

Without recovery, annual cost is roughly:

500 L × 52 weeks × 2.5 = 65,000 USD in solvent purchases.

500 L × 52 weeks × 1.0 ≈ 26,000 USD in waste disposal.

Total ≈ 91,000 USD per year.

With a solvent recycler achieving 85–90% recovery:

Only 10–15% of solvent needs to be bought as “make‑up.”

Waste volume drops by the same proportion.

Even after including electricity, maintenance, and equipment depreciation, it is common to see payback times of 12–24 months, depending on local costs and process stability.

Very small users (for example, a small workshop using only a few liters per week) may find that the cost and management of a recycler are not justified. In such cases, following best‑practice disposal guidelines and using local hazardous waste drop‑off services can be more practical. Once usage reaches tens or hundreds of liters per week, on‑site recovery usually becomes financially attractive.

4. Safety, Compliance, and Environmental Benefits

A well‑designed solvent waste recovery service is not just about saving money. It must also manage safety and regulatory responsibilities correctly.

4.1 Safe Handling of Hazardous Solvent Waste

Many common solvents are flammable or toxic. Used solvent can be even more hazardous than fresh solvent because it contains dissolved paints, oils, or reactive chemicals. This is why independent disposal without guidance can be risky.

For example, when dealing with used isopropyl alcohol, acetone, or methanol, it is important to avoid pouring them into drains or general trash. Detailed guidance on safe disposal of isopropyl alcohol is available in the articlehow to dispose of isopropyl alcohol, which covers small‑scale and industrial scenarios.

4.2 Compliance and Documentation

Solvent waste recovery services often include support for:

Correct classification of waste streams.

Record‑keeping of recovered volumes and residues.

Labels and documentation for inspections.

In regions with strict environmental rules, documented recovery can be a strong argument during audits: the site is not only disposing of waste correctly, but also actively reducing the amount of hazardous waste sent off‑site.

4.3 Environmental Impact

From an environmental perspective, solvent waste recovery services deliver three solid benefits:

Less virgin solvent production – fewer liters manufactured from fossil feedstocks.

Lower transport and incineration – reduced CO₂ and air pollutant emissions from waste handling.

Lower risk of accidental releases – fewer drums stored, moved, and opened.

A study by the U.S. EPA on solvent recycling in the coatings industry reported that on‑site recovery can reduce the mass of hazardous waste by more than 70% in certain processes, depending on the contamination level and equipment used. Numbers vary, but the direction is consistent: recovery significantly cuts waste.

5. Choosing the Right Solvent Waste Recovery Solution

When evaluating solvent waste recovery services, several practical questions should be considered.

5.1 Key Questions to Ask Suppliers

What solvents are compatible? – e.g., acetone, isopropyl alcohol, xylene, ethanol, paint thinner mixtures.

What is the typical recovery rate for the specific waste stream?

What is the recommended capacity? – daily or weekly solvent volume matters more than tank size alone.

What certifications exist? – explosion‑proof ratings, machine directives, local approvals.

What support is offered? – installation, operator training, periodic maintenance.

5.2 Matching Capacity to Real Usage

A frequent mistake is to choose a unit that is either far too small or much larger than needed. Oversized machines may run under‑loaded and return a slower payback. Undersized machines create bottlenecks, forcing part of the waste back into off‑site disposal.

As a rule of thumb, capacity should allow the site to process one to three days of solvent waste in a single batch or in a small number of batches. The table earlier shows how a 20‑liter unit (T‑20Ex) suits smaller labs or workshops, while 125–400‑liter models serve painting lines, printing houses, or metal finishing plants.

For most industrial users, sizing based on realistic medium‑term volume is more efficient than “testing” with a unit that is clearly too small. If a pilot is needed, it should still be close to the expected steady‑state demand; otherwise, the results will underestimate the real savings and may mislead decision‑makers.

6. When Do Solvent Waste Recovery Services Make the Most Sense?

Solvent waste recovery is particularly attractive in the following situations:

High, stable solvent consumption – painting lines, printing, electronics cleaning, automotive refinishing, and pharmaceutical processes.

Limited storage space – sites where many drums of waste create safety and logistical problems.

High disposal costs or remote locations – where transport is expensive or hazardous waste contractors are limited.

Strong sustainability targets – companies reporting ESG metrics or pursuing ISO 14001 certifications.

For readers interested in the broader concept and process of solvent recovery beyond a single machine, the article onwhat solvent recovery is and how it worksgives a more system‑level view.

7. Summary: From Cost Center to Circular Resource

Solvent waste recovery services turn a recurring problem—buying large quantities of solvent and paying again to dispose of it—into a controlled, partly circular process. The key points can be summarized as follows:

Used solvent is a resource, not just waste, when recovery is technically feasible and properly managed.

Modern solvent recycler machines routinely reach 80–95% recovery, depending on the waste composition.

Cost savings come from reduced solvent purchases and lower hazardous waste volumes.

Safety and compliance improve because waste streams are more controlled and better documented.

Environmental performance improves through reduced virgin solvent production and lower incineration volumes.

For organizations that regularly handle flammable or volatile solvents, it is increasingly difficult to justify treating all spent solvent as waste. With careful evaluation and the right equipment, solvent waste recovery services can move solvent management from a pure cost center to a strategic element of both cost control and sustainability.

Next Steps: Evaluate a Solvent Recycling System for Your Site

To move from theory to practice, the first step is to measure actual solvent flows: how much is purchased, how much becomes waste, and how often. With that data, it becomes straightforward to size a suitable solvent recycling system and estimate payback time.

View solvent recycling equipment options→