Every year, industries like manufacturing, pharmaceuticals, and automotive services generate vast amounts of solvent waste. This byproduct of cleaning and production processes isn't just an inconvenience—it’s a responsibility. But what happens to all this solvent waste? How is it disposed of, and is there a better way?

Let’s dive into solvent waste disposal, understand the available options, and explore practical solutions that balance cost, compliance, and environmental care.

What Is Solvent Waste?

Solvents are used for dissolving, cleaning, or processing materials in a wide range of industries. When a solvent is used, it often becomes contaminated with oils, dirt, or chemicals, rendering it ineffective. This leftover, contaminated solvent is classified as solvent waste.

Did you know that some solvent waste is considered hazardous? Substances like acetone, toluene, and methanol can be flammable, toxic, or environmentally harmful if not handled properly. Improper disposal can lead to fines, accidents, or long-term ecological damage.

Traditional Solvent Disposal Methods

Incineration

Many businesses opt to send solvent waste to incineration facilities. This method involves burning the waste at high temperatures, breaking it down into less harmful byproducts. While effective at reducing hazardous materials, it’s far from perfect.Downsides: Incineration can be costly, particularly when factoring in transportation fees to certified facilities. It also releases greenhouse gases, contributing to climate change.

Landfills

For non-hazardous solvent waste, landfill disposal might seem like an easy option. However, this approach is increasingly discouraged due to the risk of leaching chemicals into groundwater and soil. Environmental regulations are tightening, pushing businesses to explore safer practices.

Have you ever wondered, “Is there a way to reduce reliance on incineration?” The good news is, yes—there are alternatives that are both cost-effective and environmentally friendly.

Recycling Solvent Waste: A Better Approach

Recycling solvent waste has emerged as a popular alternative to traditional disposal methods. It’s not just about compliance—it's about turning waste into a reusable resource.

Here’s how recycling works:

Used solvents are processed to remove contaminants like oils, dirt, and chemicals.

The purified solvent can then be reused, reducing the need for purchasing fresh supplies.

But does recycling make sense for every business? If your operation generates a significant amount of solvent waste, recycling can save money while reducing your environmental footprint.

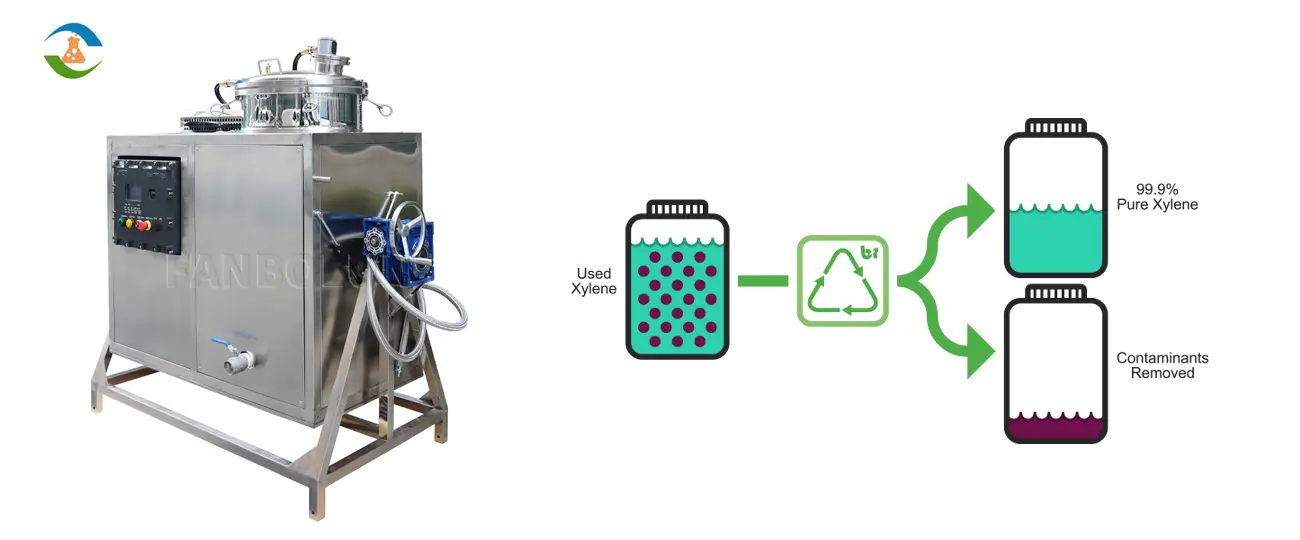

How Do Solvent Recycler Machines Help?

While recycling doesn’t always require fancy equipment, solvent recycler machines make the process more efficient. These machines use distillation technology to separate impurities from the solvent. The result? Clean, reusable solvent with minimal residue.

Quick Process: Machines can handle large volumes in short cycles.

Lower Costs: They reduce both the need for fresh solvents and the expense of disposal.

Sustainability: Recycling dramatically cuts down on waste sent to incinerators or landfills.

Solvent Recycling Equipment (90L)

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Solvent Recycler Machine (125L)

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Solvent Recycling Machine (250L)

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Recovery(%): 95

View More

Solvent Recycling System (600L)

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Recovery(%): 95

View More

Challenges of Solvent Waste Management

Managing solvent waste isn’t without its hurdles. Let’s address some common concerns:

1. What if the solvent is too contaminated to recycle?

In some cases, heavily degraded or mixed solvents may not be suitable for recycling. These may still require incineration or specialized treatment. However, regular maintenance of recycling systems can improve efficiency and extend the range of recyclable solvents.

2. Is recycling worth the upfront cost?

While solvent recycler machines represent an investment, the long-term savings on solvent purchases and disposal fees often make up for it. Businesses should calculate their break-even point to make informed decisions.

Practical Steps for Better Solvent Waste Management

Assess Your Waste

Start by evaluating the types and quantities of solvent waste your business generates. Understanding what you’re dealing with is crucial for selecting the right disposal or recycling method.Follow Local Regulations

Solvent disposal laws vary by country and region. Ensure that your practices comply with local guidelines to avoid penalties and legal issues.Choose Sustainable Practices

Whether it’s recycling, reducing solvent use, or adopting non-toxic alternatives, look for ways to minimize waste generation in the first place.Partner With Experts

Consider working with waste management professionals or recycling equipment suppliers. They can offer tailored solutions to meet your needs.

Why Responsible Solvent Disposal Matters

Have you ever stopped to think about where your solvent waste ends up? Improper disposal can lead to groundwater contamination, soil degradation, and air pollution. Beyond environmental harm, mishandling solvent waste can hurt a company’s reputation and bottom line.

Choosing better disposal methods isn’t just about avoiding fines—it’s about safeguarding the planet and ensuring the long-term sustainability of your operations.

Final Thoughts

Solvent waste disposal doesn’t have to be a complex or costly burden. By understanding your options and exploring technologies like solvent recycler machines, you can turn waste into a resource, save money, and reduce your environmental impact.

So the next time you’re dealing with solvent waste, ask yourself: “Am I making the most of what I have?” A little effort today can lead to big savings and a cleaner tomorrow.