Acetone Recycling – Benefits, Process & Machines

A comprehensive guide on why acetone recycling is essential for environmental preservation and industrial efficiency

Learn the Recycling ProcessUnderstanding Acetone and Its Uses

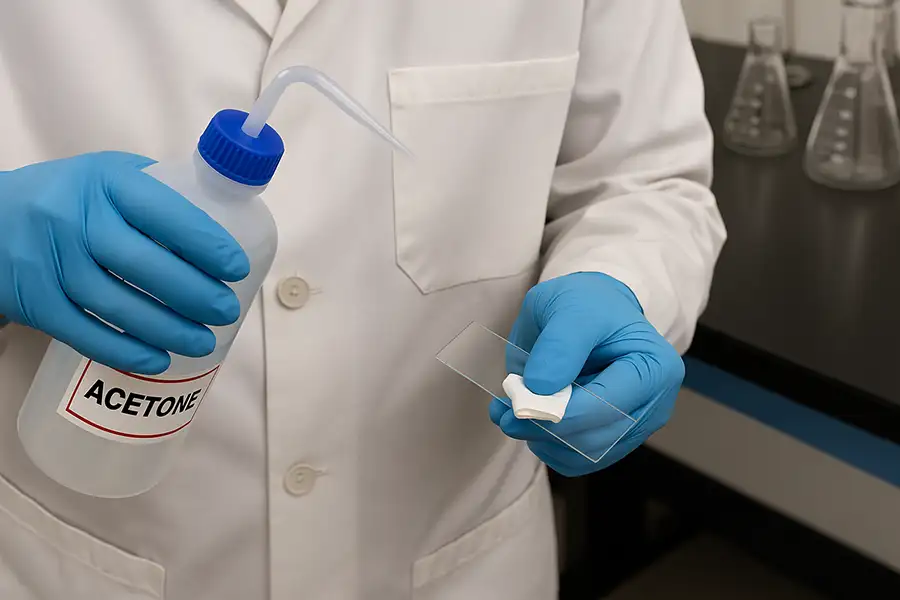

Acetone (C3H6O) is a widely used solvent in industries such as pharmaceuticals, cosmetics, electronics, and manufacturing. Known for its excellent dissolving power, it's a staple in nail polish removers, paint thinners, and laboratory cleaning agents.

However, excessive disposal without recovery contributes to environmental pollution and resource waste. Proper recycling methods allow industries to utilize this valuable solvent repeatedly.

Used in processing medications and cleaning lab equipment

Essential component in thinners, varnishes, and finishes

Used in cleaning circuit boards and electronic components

Primary component in nail polish removers

Why Recycle Acetone?

Recycling acetone is not just about cost savings—it's a step toward circular chemical economy. According to the U.S. Environmental Protection Agency (EPA), over 2.6 million gallons of solvent waste are generated annually from industrial facilities in the U.S. alone.

Economic Savings

Reduce solvent purchasing costs by 70-90% through recycling programs.

Environmental Impact

Minimize release of pollutants and reduce carbon footprint significantly.

Regulatory Compliance

Meet strict EPA and international regulations for solvent disposal.

How Does Acetone Recycling Work?

Acetone recycling typically involves a distillation process, where the solvent is heated until it vaporizes, then cooled to condense back into a purified liquid. This technique is highly effective since acetone has a relatively low boiling point (56°C).

Distillation-Based Benefits:

Industrial Recycling Process in 4 Steps

Collection

Used acetone is collected in specialized containers to prevent evaporation and contamination.

Distillation

Contaminated solvent is heated to precisely 56°C to vaporize acetone, separating it from impurities.

Condensation

Acetone vapor passes through cooling system, returning to liquid state with high purity of 99%+.

Reuse

Purified acetone is dispensed into clean containers for reuse in industrial processes.

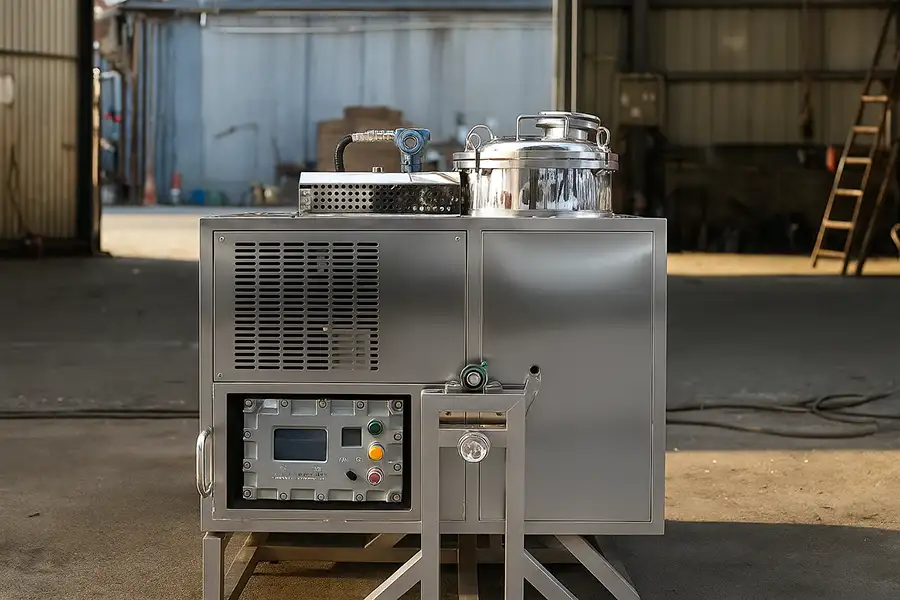

Industrial Acetone Recycling Machines

Modern solvent recycling systems are designed to handle various volumes of contaminated solvents, automatically separating impurities. These systems provide efficient, sustainable solutions for industrial needs.

Thinner Recycler Machine

Capacity: 5 gallons per batch

Recovery: 95-99% purity

Ideal for small labs and research facilities. Compact footprint with fully automated controls.

Solvent Recycler Machine

Capacity: 25 gallons per batch

Recovery: 99.9% purity

For medium-scale manufacturing. Features multiple safety sensors and energy recovery systems.

Solvent Recycling System

Capacity: Continuous processing

Recovery: >99.9% purity

Fully automated system for large industrial plants. Energy efficient with IoT connectivity features.

Environmental and Economic Benefits

Recycling acetone contributes to sustainability goals while cutting operational costs. Based on a 2023 MIT research study, industries that adopt circular economy practices can reduce waste output by more than 40% within five years.

| Indicator | Traditional Disposal | With Recycling | Reduction |

|---|---|---|---|

| Annual Waste Volume | 2,600 gal | 520 gal | 80% |

| CO2 Emissions | 12,300 kg | 2,460 kg | 80% |

| Fresh Solvent Cost | $45,000 | $9,000 | 80% |

| Disposal Fees | $18,400 | $3,680 | 80% |

Cost and environmental impact analysis for a medium-sized facility (12-month period)

"Implementing an acetone recycling system was transformative. We reduced our solvent costs by 87% and significantly decreased our environmental compliance risks. The system paid for itself in just 9 months."

Director of Operations, Precision Manufacturing Ltd.

Environmental benefits include:

Reduced landfilling: Less hazardous waste needs disposal

Carbon reduction: Smaller footprint from avoiding new solvent production

Water conservation: Prevents groundwater contamination

Resource preservation: Diminished demand for raw petroleum materials

Compliance satisfaction: Meeting evolving environmental regulations

Ready to Transform Your Waste Management?

Discover how acetone recycling can cut costs while boosting your environmental performance

Request a Custom QuotationConclusion

Acetone recycling is a crucial component of sustainable chemical management in modern industry. By implementing advanced solvent recovery systems, businesses achieve significant environmental benefits while realizing substantial cost savings.

The key takeaways:

Economic advantage: Systems typically pay for themselves in 6-12 months

Environmental responsibility: Dramatic reduction in hazardous waste

Regulatory compliance: Simplifies hazardous waste management

Quality assurance: Consistently high purity meets industrial requirements

Whether you operate a small lab or major manufacturing plant, investing in an acetone recycling system represents one of the most impactful sustainability improvements available today.