Dealing with butanol waste can be tricky. Are you concerned about safety, environmental rules, and rising disposal costs? It's a common challenge for many businesses like yours.

Proper butanol waste disposal means handling it safely, following regulations, and looking for ways to reduce or recycle it. Using a solvent recovery system is a smart choice. It can help you purify and reuse butanol, saving money and protecting the environment.

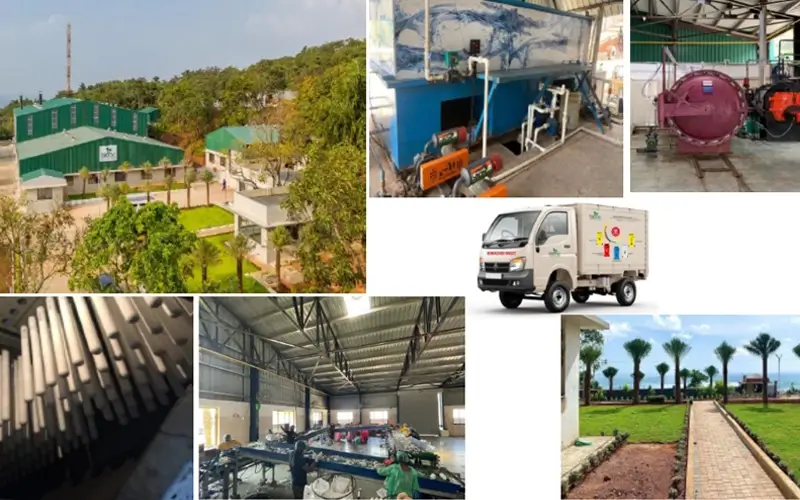

As a company, we've seen many clients struggle with this. The good news is that there are effective solutions. For over 16 years, we've been helping businesses like yours navigate these challenges. We specialize in equipment that not only meets but exceeds international standards. Let me share some insights into managing butanol waste effectively. This can turn a problem into an opportunity.

Why Is Proper Butanol Disposal So Critically Important?

Ignoring butanol waste rules can lead to big fines and safety risks. This isn't just about rules; it's about protecting people and our planet. Many don't realize the full impact.

Proper butanol disposal is vital to prevent fires, health problems from fumes, and environmental damage. Following rules keeps your workplace safe, avoids legal issues, and shows your company cares about responsibility. It's a key part of sustainable operations.

Understanding the "why" behind proper butanol disposal can really change how we approach it. It's not just a chore; it's a crucial part of responsible business. Let's break down the main reasons.

Preventing Safety Hazards

Butanol is flammable. This means it can easily catch fire if not handled correctly. Think about vapours building up in a poorly ventilated area, or a stray spark. The risk is real. Proper disposal methods, including using the right containers and storage, minimize these fire risks. We also need to think about worker safety. Exposure to butanol fumes can irritate the eyes, skin, and respiratory system. Long-term exposure can lead to more serious health issues. So, correct handling and disposal protect your team.

Protecting Our Environment

If butanol waste isn't managed properly, it can cause serious harm to the environment. Spills or improper dumping can contaminate soil and water. This affects plants, animals, and even our drinking water sources. As a manufacturer that exports to 87 countries, we see how seriously environmental protection is taken globally. Being responsible means ensuring our industrial activities don't harm the planet for future generations. This is a core value we try to instill through our equipment solutions.

Meeting Legal and Regulatory Requirements

Governments around the world have strict regulations for hazardous waste, and butanol often falls into this category. These rules cover everything from how you store it to how you transport and finally dispose of or treat it. Not following these rules can lead to hefty fines, legal action, and damage to your company's reputation. Staying compliant is not just about avoiding penalties; it's about being a good corporate citizen. We always advise our clients to be thoroughly familiar with their local regulations. Our equipment is designed with compliance in mind, holding ISO9001 and CE certificates.

What Are the Common Methods for Butanol Waste Disposal, and Their Downsides?

Are you just sending your butanol waste away? This might seem easy but can be costly and not very green. There might be better ways you haven't considered.

Common butanol disposal includes incineration or sending it to specialized landfills. However, these methods can be expensive, have environmental impacts, and mean losing a valuable resource. They also carry ongoing liability for your business.

When businesses face butanol waste, they often turn to a few standard disposal routes. However, each of these comes with its own set of challenges. It's important to weigh these carefully.

Incineration

One common method is incineration. This involves burning the butanol waste at very high temperatures. While it can effectively destroy the hazardous components, it's not without problems. Incineration can release pollutants into the air if not done with advanced filtration systems. It also contributes to greenhouse gas emissions. Furthermore, the cost of incineration can be quite high, especially for large volumes of waste. You're essentially paying to destroy a chemical that might still have value. From my experience talking to clients, this is often a significant operational expense they wish to reduce.

Landfilling

Another option is sending the waste to specialized hazardous waste landfills. These landfills are designed to prevent contaminants from leaking into the environment. However, landfill capacity is limited, and the long-term environmental risks, even with engineered liners, are a concern for many. There's also the "cradle-to-grave" liability, meaning your company remains responsible for that waste indefinitely, even after it has left your site. If that landfill ever leaks, your company could be held accountable. Plus, this method completely wastes the butanol.

Discharge to Water (Regulated)

In some very specific, highly regulated cases, and after significant pre-treatment, some wastewater containing very low concentrations of solvents might be discharged. However, for typical butanol waste, this is rarely a viable or environmentally sound option due to its hazardous nature and potential to harm aquatic ecosystems. The regulatory hurdles are immense, and the risk of non-compliance is severe.

These traditional methods highlight a key issue: they treat butanol waste purely as a problem to get rid of, rather than a potential resource to recover. This is where our philosophy as a manufacturer of recovery systems comes in. We believe in turning waste streams into value streams.

How Can Solvent Recovery Systems Help with Butanol Waste?

Tired of paying for butanol disposal? What if you could get that solvent back, pure and ready to reuse? It sounds good, right? And it's very possible.

Solvent recovery systems separate butanol from waste mixtures through processes like distillation. This allows you to reclaim pure butanol for reuse, drastically cutting disposal costs and the need to buy new solvent. It's an eco-friendly and economical solution.

Solvent recovery is a game-changer for handling butanol waste. Instead of just disposing of it, you can reclaim valuable butanol. As a company dedicated to laboratory and industrial equipment for over 16 years, we've seen firsthand how this technology benefits businesses. Let's explore how.

The Principle of Solvent Recovery

Most solvent recovery systems, especially for solvents like butanol, work on the principle of distillation. It's a bit like how distilleries make spirits. The waste mixture containing butanol is heated. Since different substances have different boiling points, butanol will evaporate at its specific temperature. These butanol vapors are then cooled and condensed back into a liquid form – now much purer. The contaminants, which might have higher boiling points or are non-volatile, remain behind in the distillation vessel. Our systems, like rotary evaporators or short-path distillation units, are designed to do this efficiently and safely.

Benefits of Using a Solvent Recovery System for Butanol

The advantages are significant:

Cost Savings: This is often the biggest driver. You dramatically reduce the amount you spend on buying new butanol. You also save a lot on hazardous waste disposal fees. I've worked with companies that saw a return on their investment in our solvent recovery machines in less than a year.

Environmental Responsibility: By recovering and reusing butanol, you reduce your environmental footprint. Less waste goes to landfills or incinerators. You also conserve resources by not needing as much virgin solvent, which takes energy and raw materials to produce. This aligns with the growing demand for sustainable practices.

Consistent Supply: Relying on recovered solvent can give you a more stable and predictable supply, sometimes insulating you from price fluctuations or supply chain disruptions for new solvent.

Improved Safety and Compliance: By treating waste on-site, you reduce the risks associated with storing and transporting large quantities of hazardous waste. Our systems are built to meet international safety standards (CE certified), helping you maintain compliance.

Many of our customers, from chemical companies to research institutions, initially come to us looking to solve a disposal problem. They quickly find that a solvent recovery system is actually an investment that pays back in multiple ways. It's about being smarter with your resources.

What Should I Look for When Choosing a Butanol Solvent Recovery System?

Ready to consider a recovery system? With many options, how do you pick the right one for your butanol waste? It's key to choose wisely for best results.

Key factors include recovery efficiency, capacity matched to your waste volume, safety features (explosion-proof options), ease of use, and supplier support. Look for durable materials and compliance with safety standards like CE.

Choosing the right solvent recovery system for your butanol waste is a crucial decision. As a manufacturer with extensive experience—16 years in production and export—we understand the critical aspects that ensure you get a reliable and efficient solution. Here’s what I always advise clients to consider:

1. Recovery Rate and Purity

How much butanol can the system recover, and how pure will it be? You want a high recovery rate to maximize your savings. The required purity will depend on your specific reuse application. Some processes need very high purity, while others are more tolerant. Discuss your needs with the supplier. Our equipment is designed for high-efficiency separation.

2. Capacity and Throughput

The system must be able to handle the volume of butanol waste you generate. Consider your daily or weekly waste output. It’s also wise to think about future needs. Will your production increase? Choosing a system with slightly more capacity than you currently need might be a good long-term strategy. We offer a range of sizes, from lab-scale to production-scale units.

3. Safety Features

Since butanol is flammable, safety is paramount. Look for features like:

Explosion-proof design (especially for electrical components if operating in hazardous areas).

Over-temperature protection.

Pressure relief valves.

Leak detection.

4. Ease of Operation and Maintenance

The system should be user-friendly. How easy is it to load waste, run the cycle, and collect the recovered solvent? What about cleaning and routine maintenance? A system that is complex to operate or maintain can lead to downtime and increased labor costs. We focus on intuitive designs and provide comprehensive operating manuals.

5. Material of Construction

The materials used to build the recovery system should be compatible with butanol and any other chemicals present in your waste stream. Stainless steel is often a good choice for its corrosion resistance and durability. Gaskets and seals must also be made of resistant materials.

6. Supplier Reputation and Support

Choose a supplier with a proven track record and good customer support. What kind of warranty do they offer? Do they provide installation assistance, training, and after-sales service? As the first manufacturer in China with a 24/7 after-sales support team, we understand how important ongoing support is for our global customers in 87 countries.

Making the right choice means your solvent recovery system will be a valuable asset for years to come, helping you manage butanol waste efficiently and economically.

Conclusion

Effectively managing butanol waste is crucial. Solvent recovery offers a cost-effective, environmentally friendly solution, turning waste into a reusable asset for your operations. We can help you achieve this.