In today’s fast-paced industrial environment, efficiency and sustainability have become crucial goals for companies across various sectors. One area where these objectives intersect is in the use of solvents, particularly Gun Wash, and the implementation of solvent recycling systems. This article explores the benefits of using Gun Wash, the importance of solvent recyclers, and how these elements can enhance both productivity and environmental responsibility.

What is Gun Wash?

Gun Wash is a specialized solvent mixture used primarily for cleaning spray guns and other painting equipment. It is designed to dissolve paint residues, ensuring that tools are kept in optimal working condition. The effectiveness of Gun Wash makes it a popular choice in industries such as automotive, manufacturing, and woodworking, where spray painting is a common process.

The Role of Solvent Recyclers

As beneficial as Gun Wash is, its repeated use can lead to significant waste generation. This is where solvent recyclers come into play. A solvent recycler is a machine that purifies used solvents, including Gun Wash, allowing them to be reused multiple times. By implementing solvent recycling systems, companies can significantly reduce their solvent consumption, leading to cost savings and a smaller environmental footprint.

Benefits of Using Gun Wash

1. Enhanced Cleaning Efficiency

Gun Wash is specifically formulated to break down paint residues quickly and effectively. This high level of efficiency means that equipment can be cleaned thoroughly with less effort and in less time, which can improve overall productivity in the workplace.

2. Equipment Longevity

Regular and effective cleaning with Gun Wash can extend the life of spray guns and other painting equipment. By preventing the build-up of paint residues, Gun Wash helps maintain the performance of these tools, reducing the frequency of repairs and replacements.

3. Improved Paint Quality

Clean equipment ensures that paint is applied smoothly and evenly, resulting in a higher quality finish. This is particularly important in industries where the appearance of the final product is critical, such as automotive manufacturing and furniture production.

Why Invest in Solvent Recyclers?

1. Cost Savings

One of the most immediate benefits of using solvent recyclers is the reduction in solvent purchasing costs. By recycling Gun Wash, companies can reuse the same solvent multiple times, decreasing the need to buy new solvent supplies frequently.

2. Environmental Responsibility

Solvent recycling significantly reduces the amount of hazardous waste generated by industrial processes. This not only helps in complying with environmental regulations but also demonstrates a company’s commitment to sustainable practices. Recycling solvents reduces the demand for new solvent production, which can lower the overall environmental impact.

3. Operational Efficiency

Solvent recyclers can streamline operations by providing a steady supply of clean solvent. This ensures that equipment cleaning processes are not delayed by the need to purchase and receive new solvents. With an in-house recycling system, companies can maintain a continuous workflow, improving overall efficiency.

How Do Solvent Recyclers Work?

Solvent recyclers operate on a relatively simple principle. Used solvent, such as Gun Wash, is collected and heated to separate the solvent from the contaminants. The purified solvent is then collected and ready for reuse, while the concentrated waste is safely disposed of. This process can be repeated multiple times, maximizing the use of each batch of solvent.

Key Considerations for Implementing Solvent Recyclers

When considering the implementation of solvent recyclers, there are several factors to keep in mind:

1. Initial Investment

While the long-term savings are significant, the initial cost of purchasing and installing solvent recycling equipment can be substantial. Companies need to evaluate their budget and consider the return on investment over time.

2. Space Requirements

Solvent recyclers vary in size, and it’s important to ensure that there is adequate space in the facility for the equipment. Additionally, the location should be chosen to minimize disruptions to existing workflows.

3. Training and Maintenance

Proper training for staff is essential to ensure the efficient operation of solvent recyclers. Regular maintenance is also necessary to keep the equipment functioning optimally. Companies should consider these ongoing responsibilities when planning for solvent recycling systems.

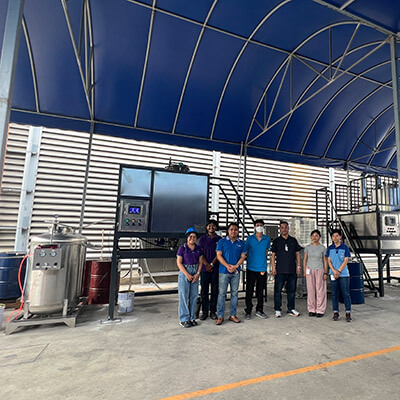

Case: Success with Gun Wash and Solvent Recycling

To illustrate the benefits of using Gun Wash and solvent recyclers, let’s look at a case of an automotive manufacturing company. Before implementing solvent recycling, the company was spending a significant amount on purchasing new solvents and managing hazardous waste disposal. By integrating solvent recyclers into their process, they were able to cut their solvent purchasing costs by 50% and reduce their hazardous waste by 75%.

The improved cleaning efficiency also meant that their spray guns lasted longer and produced higher quality finishes, leading to increased customer satisfaction. This case study demonstrates the tangible benefits of combining Gun Wash with solvent recycling systems.

Conclusion

The use of Gun Wash and solvent recyclers represents a significant opportunity for companies to enhance both their efficiency and sustainability. By investing in these technologies, businesses can realize substantial cost savings, improve the quality of their products, and reduce their environmental impact. As the industrial landscape continues to evolve, embracing such innovations will be key to staying competitive and responsible.

Isn’t it time to consider how solvent recyclers can revolutionize your company’s operations? By making this strategic investment, companies can not only improve their bottom line but also contribute to a more sustainable future.

Incorporating Gun Wash and solvent recyclers into your workflow is not just a smart financial decision; it’s a commitment to better business practices and a healthier planet. So, what are you waiting for? Start exploring the possibilities of solvent recycling today!