In the world of painting and coating, paint thinner is a vital solvent used to clean brushes, thin paints, and remove oil-based paints from surfaces. However, disposing of used paint thinner improperly can have serious environmental consequences. That's where solvent recycling systems come into play. These systems offer an efficient and eco-friendly way to recycle paint thinner, saving money and reducing waste. This article will explore the importance of recycling paint thinner, how solvent recycling systems work, and additional aspects to consider for effective recycling.

The Importance of Recycling Paint Thinner

Paint thinner is a hazardous material. When not disposed of correctly, it can contaminate soil and water, posing significant risks to both human health and the environment. Recycling paint thinner helps to:

Reduce Environmental Impact: By recycling paint thinner, you prevent hazardous chemicals from entering landfills and water systems.

Save Money: Recycled paint thinner can be reused, reducing the need to purchase new solvents.

Comply with Regulations: Proper disposal and recycling of paint thinner ensure compliance with local and federal environmental regulations.

Given these benefits, it's clear why recycling paint thinner is not only an environmental responsibility but also an economic advantage. But how does one go about recycling this solvent effectively?

How Solvent Recycling Systems Work?

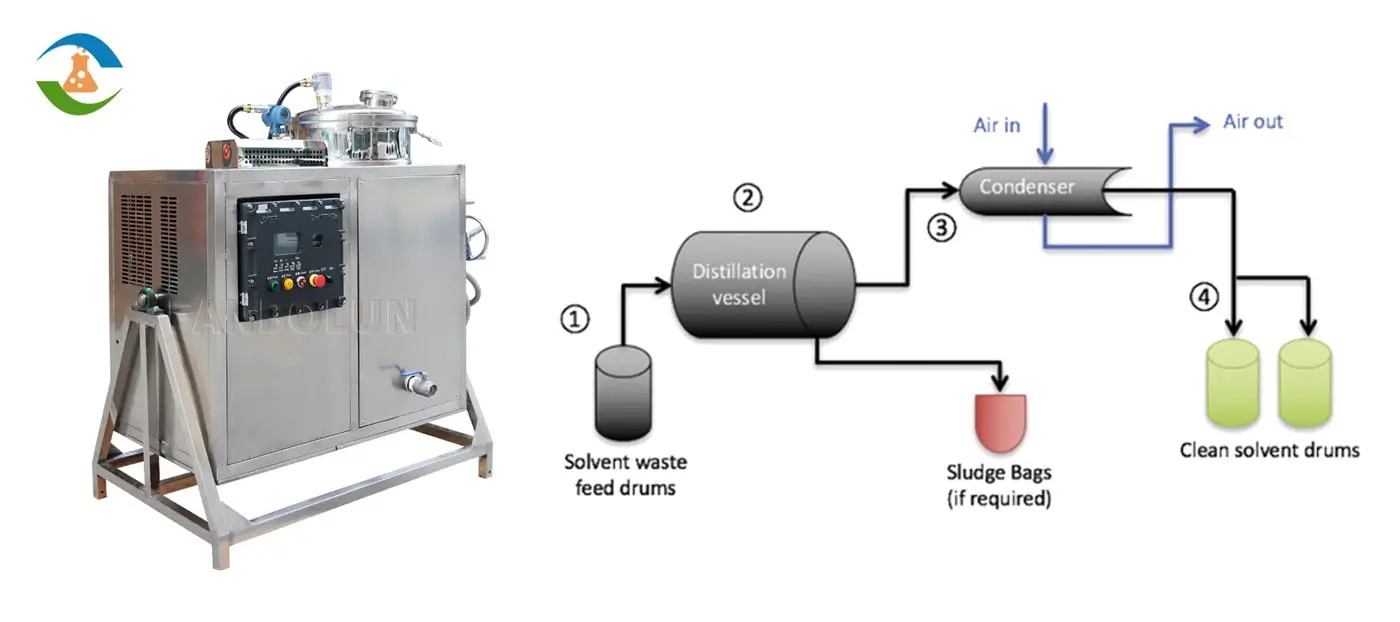

Solvent recycling systems are designed to recover and purify used solvents, making them reusable. The process typically involves the following steps:

Collection: Used paint thinner is collected in a designated container. It’s crucial to ensure that the container is properly labeled and sealed to prevent leaks and contamination.

Filtration: The collected solvent is filtered to remove solid particles and impurities. This is often done through a multi-stage filtration process.

Distillation: The filtered solvent undergoes distillation, where it is heated to separate the paint thinner from other contaminants based on their boiling points.

Condensation: The vaporized solvent is then condensed back into a liquid form, which is now purified and ready for reuse.

Storage: The recycled paint thinner is stored in a clean container, ready to be used for future projects.

Have you ever wondered how much paint thinner can be saved through recycling? It’s estimated that a well-maintained solvent recycling system can recover up to 90% of the used solvent, making it a highly efficient process.

Benefits of Using a Solvent Recycling System

Utilizing a solvent recycling system offers numerous advantages:

Cost Savings: By reusing paint thinner, companies can significantly reduce their solvent purchasing costs.

Environmental Protection: Recycling minimizes the amount of hazardous waste that needs to be disposed of, thus protecting the environment.

Regulatory Compliance: Many jurisdictions have strict regulations regarding the disposal of hazardous waste. Using a recycling system helps ensure compliance with these laws.

Operational Efficiency: Solvent recycling systems are designed to be user-friendly and can be integrated into regular operations with minimal disruption.

Choosing the Right Solvent Recycling System

When selecting a solvent recycling system, several factors need to be considered:

Capacity: Determine the volume of paint thinner you need to recycle on a regular basis. Systems vary in capacity, so choose one that matches your needs.

Type of Solvent: Ensure the system is compatible with the type of paint thinner you use. Some systems are designed for specific solvents.

Space: Consider the space available in your facility for installing the recycling system.

Cost: Evaluate the initial investment versus the long-term savings. While some systems may have a higher upfront cost, the savings from reduced solvent purchases can make them more economical in the long run.

Maintenance: Look into the maintenance requirements of the system. A reliable system should be easy to maintain and operate.

Solvent Recycling Equipment (90L)

Model: T-90EX

Feed capacity(L): 90

Power(kW): 5

Recovery(%): 95

View More

Solvent Recycler Machine (125L)

Model: T-125EX

Feed capacity(L): 125

Power(kW): 6

Recovery(%): 95

View More

Solvent Recycling Machine (250L)

Model: T-250EX

Feed capacity(L): 250

Power(kW): 16

Recovery(%): 95

View More

Solvent Recycling System (600L)

Model: T-600EX

Feed capacity(L): 600

Power(kW): 32

Recovery(%): 95

View More

Implementing Solvent Recycling in Your Business

Integrating a solvent recycling system into your business operations requires careful planning:

Assessment: Start by assessing your current solvent usage and waste generation. This will help you determine the capacity and type of recycling system you need.

Training: Train your staff on the importance of recycling and how to properly use the recycling system. This ensures smooth implementation and maximum efficiency.

Monitoring: Regularly monitor the performance of the recycling system. Keep track of the amount of solvent recycled and the savings achieved.

Adjustment: Be prepared to make adjustments to optimize the recycling process. This might include fine-tuning the filtration stages or adjusting the distillation settings.

Did you know that some companies have reported savings of up to 50% on their solvent costs by implementing an efficient recycling system? This highlights the significant economic benefits alongside the environmental ones.

Additional Dimensions of Solvent Recycling

While solvent recycling systems are the primary method for recycling paint thinner, there are other aspects to consider:

Waste Minimization: Reduce the amount of paint thinner used by adopting more efficient painting techniques and using alternative cleaning methods where possible.

Substitution: Consider using less hazardous solvents or solvent-free alternatives to minimize environmental impact.

Regulatory Compliance: Stay updated with local and federal regulations regarding hazardous waste disposal and recycling. Compliance not only avoids legal issues but also promotes a positive environmental image for your company.

Community Engagement: Educate and engage with your community about the importance of recycling hazardous materials. This can enhance your company’s reputation and encourage wider adoption of recycling practices.

Conclusion

Recycling paint thinner is an essential practice for any business involved in painting and coating. By using a solvent recycling system, companies can significantly reduce their environmental impact, save money, and comply with regulations. Implementing a recycling system requires careful planning and ongoing monitoring, but the benefits far outweigh the efforts.

Have you considered how implementing a solvent recycling system could benefit your business? With the right approach and commitment, recycling paint thinner can lead to substantial economic and environmental gains. Embrace solvent recycling today and contribute to a cleaner, more sustainable future.