Grease Recycling & Oil Recovery Solutions

Turning industrial waste into valuable resources with cutting-edge solvent recycling technology

Why Grease Recycling Matters

Grease recycling, also known as oil recovery, is the process of collecting used grease, oils, and lubricants and reprocessing them into reusable materials. This revolutionary approach not only minimizes industrial waste but also offers significant cost savings. According to the U.S. Environmental Protection Agency, recycling used oil can save over 1 billion gallons of oil annually in the United States alone, conserving valuable natural resources while protecting our environment.

How Our Recycling Technology Works

The advanced recycling process involves four meticulous stages that ensure maximum efficiency and purity. Modern solvent recycling machines utilize cutting-edge technology for optimal separation of contaminants from reusable oil. According to MIT research, automation and AI in recycling improve efficiency by over 40% and reduce operational costs by 25-30%.

Collection

Automated pumps gather waste oils from various sources with precision

Filtration

Multi-stage filtration removes particulates down to 5 microns

Separation

Centrifugal technology separates grease from solvents with 98% efficiency

Purification

Final distillation achieves industrial-grade purity for immediate reuse

Key Benefits of Recycling Technology

Significant Cost Reduction

Reduce expenses by 50-90% on new solvent purchasingEnvironmental Responsibility

Minimize hazardous waste and reduce carbon footprintRegulatory Compliance

Meet strict environmental regulations with automated reportingWorkplace Safety

Reduce hazardous material handling by up to 85%

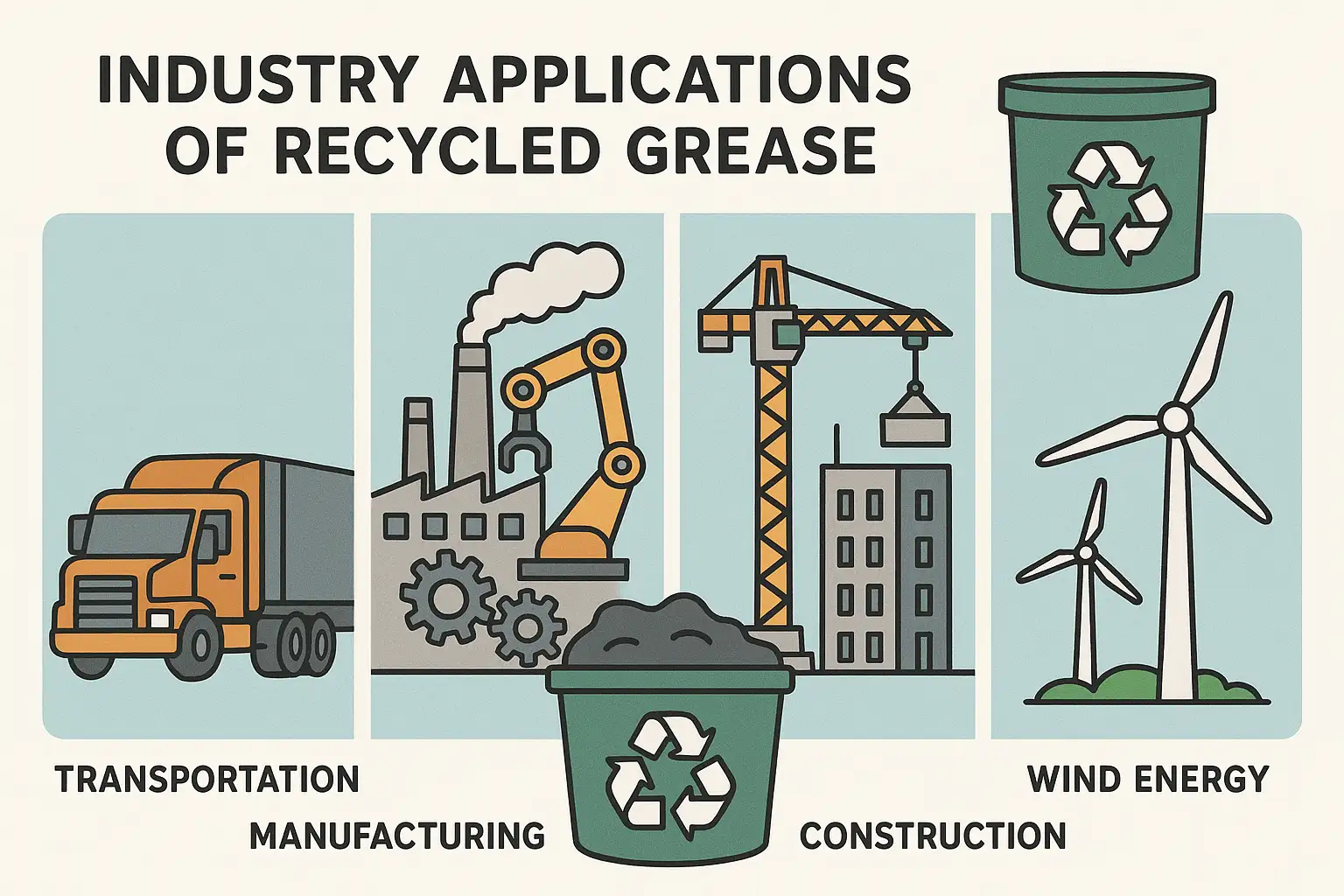

Industrial Applications

Recycled grease is used across diverse industries as a cost-effective, high-performance solution: as machinery lubricants in manufacturing, component protectants in aerospace assemblies, and blending agents in biofuel production.

System Efficiency Data

| Process Stage | Efficiency (%) | Energy Use (kWh) | Output Quality | Time Required |

|---|---|---|---|---|

| Collection | 95 | 10 | Pre-separation | 15 min |

| Filtration | 90 | 15 | 5μm purity | 30 min |

| Separation | 96 | 18 | Base separation | 45 min |

| Purification | 98 | 20 | Industrial grade | 60 min |