Eco-Friendly Technology

Wastewater Recycling System: Recovering Solvents from Industrial Wastewater

Efficiently recovering valuable solvents while reducing environmental impact and operational costs

Industrial wastewater often contains valuable organic solvents that can be recovered and reused. A wastewater recycling system designed for solvent recovery not only helps companies cut costs but also reduces environmental pollution. This article explains how these systems work, why they're important, and how industries can benefit from adopting them.

Cost Reduction

Up to 60%

Solvent purchasing savings

Environmental Impact

90%

Pollutant reduction

Waste Reduction

75%-90%

Less chemical waste to dispose

Why Solvent Recovery Matters

Many manufacturing processes—such as painting, printing, pharmaceuticals, and electronics—use solvents like acetone, isopropyl alcohol, and methanol. These solvents often end up in wastewater streams. Disposing of them without treatment can lead to environmental hazards and regulatory fines. With a solvent recycling system, these chemicals can be separated from the water and reused.

Could recovering solvents from wastewater actually save companies money?

Absolutely.

By reusing recovered solvents, companies can reduce purchasing costs by up to 60%. Additionally, they save on disposal fees and avoid potential penalties for improper waste handling. The average payback period for investing in solvent recovery systems is typically 12-18 months.

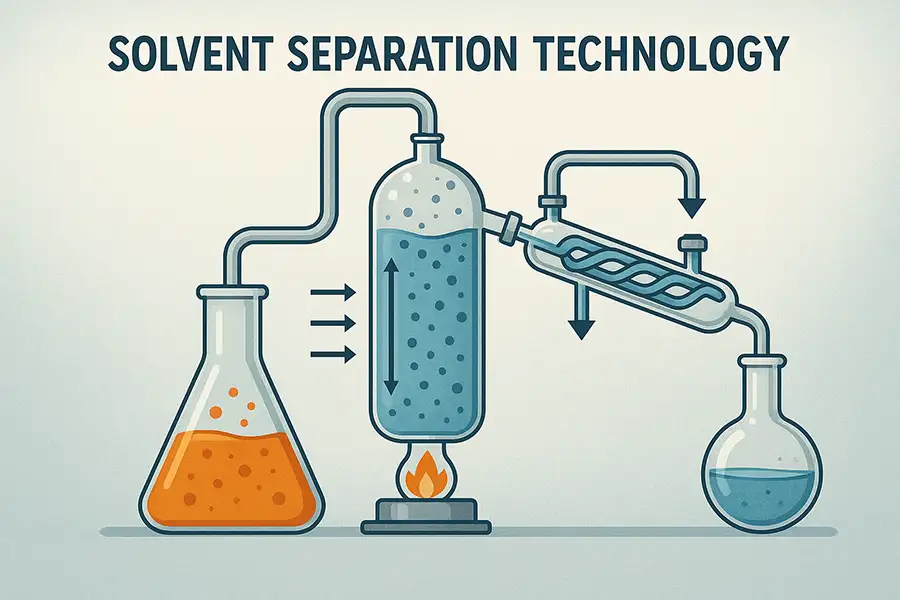

How a Wastewater Recycling System Works

The process typically involves several steps. Modern systems are designed to work continuously with minimal human intervention while ensuring optimal solvent recovery.

Pre-treatment

Removing large particles and adjusting pH levels to prepare for the main recovery process

Separation

Using distillation, filtration, or membrane technology to isolate solvents

Purification

Refining the recovered solvent to meet quality standards for reuse

Reuse

Returning the purified solvent back to production lines for reuse

Environmental Impact

According to the U.S. Environmental Protection Agency (EPA), industrial wastewater accounts for a significant portion of chemical pollution in rivers and lakes. By implementing a solvent recovery system, companies can drastically reduce their environmental footprint.

Benefits for Environmental Compliance

Reduced Chemical Discharge

Up to 95% reduction in solvent discharge to water bodies

Compliance Assurance

Meet strict environmental regulations and avoid penalties

Sustainable Operations

Improve corporate image and qualify for green certifications

Is it difficult to integrate a wastewater recycling system into existing operations?

In most cases, no.

Modern systems are modular and can be tailored to fit existing infrastructure. For example, solvent recycler machines are designed to be plug-and-play, requiring minimal downtime during installation. Most facilities see less than 24 hours of disruption during implementation.

Industry Insight

Technological innovations like AI and automation have transformed wastewater treatment. Modern solvent recovery systems can operate with 90% efficiency while reducing labor requirements by up to 40%.

Cost-Benefit Analysis

Here's a comprehensive overview of potential savings from solvent recovery:

| Factor | Without Recycling | With Recycling | Reduction (%) |

|---|---|---|---|

| Solvent Purchase Cost | $100,000/year | $40,000/year | 60% |

| Waste Disposal Fees | $25,000/year | $5,000/year | 80% |

| Regulatory Compliance | High risk of fines ($15,000-$50,000) | Low risk | >90% |

| Energy Consumption | $18,000/year | $15,000/year | 16.7% |

| System Maintenance | N/A | $12,000/year | - |

| TOTAL SAVINGS | $143,000/year | $72,000/year | $71,000/year |

Industries Using Wastewater Recycling Systems

Common industries that benefit from solvent recovery include:

Automotive manufacturing

Pharmaceutical production

Printing and packaging

Chemical processing

Electronics manufacturing

Paint and coatings

Can wastewater recycling systems handle multiple types of solvents?

Yes.

Advanced systems can recover a wide range of solvents, from alcohols to hydrocarbons, by adjusting process parameters and using multi-stage separation technologies. Most modern systems are designed to handle solvent mixtures with purity rates exceeding 98%.

Pro Tip:

When selecting a system, choose modular designs that allow for future expansion or configuration changes to accommodate different solvent types as your operations evolve.

Conclusion

A wastewater recycling system is a smart investment for any industry dealing with solvent-rich wastewater. Not only does it save money, but it also protects the environment, ensures compliance with regulations, and enhances corporate sustainability credentials.

Modern recovery systems are efficient, cost-effective, and surprisingly affordable. The return on investment typically ranges from 12-24 months, with continued savings throughout the equipment lifecycle.

For more insights, explore our detailed guide on how a solvent recovery system works.