Struggling with complex hazardous waste rules and rising disposal costs? You want to be safe and save money, but it feels hard. We understand this problem very well.

Your business can improve hazardous waste disposal by understanding waste types, following rules, and using smart tech like solvent recovery. This approach cuts risks, costs, and helps the planet.

Dealing with hazardous materials is a big part of many industries. We have seen companies worry about this for years. It is not just about following laws. It is about keeping people safe and our environment clean. As a company that makes lab and industrial gear, we have spent over 16 years helping businesses like yours. We want to share what we have learned to make this easier for you.

What Really Makes Industrial Waste Hazardous And Why Worry?

Are you unsure if your company's waste is "hazardous"? Many materials used daily in labs and factories can become hazardous waste, posing risks if not handled correctly. This uncertainty can be costly.

Industrial waste is hazardous if it can harm human health or the environment. This includes materials that are ignitable, corrosive, reactive, or toxic. Understanding this helps prevent serious problems.

Let's look deeper into what makes something hazardous. Governments worldwide have lists and rules. Generally, waste is hazardous if it has certain properties. We often talk about four main types. I remember a client who was surprised to learn that some of their common cleaning agents were considered hazardous because of their corrosive nature. This is a common experience. Proper solvent waste management is key.

Key Characteristics of Hazardous Waste:

Ignitable: These wastes can easily catch fire. Think of certain solvents or paint thinners. We've seen how quickly an accident can happen if these are stored or disposed of improperly.

Corrosive: These can rust or dissolve metals or burn skin. Acids and strong bases are common examples. I recall a lab that had issues with corroded pipes due to improper acid disposal.

Reactive: These wastes are unstable. They can explode or release toxic fumes if mixed with water or other chemicals. Certain old chemicals can become reactive over time if not managed.

Toxic: These are harmful or fatal if swallowed or absorbed. This includes wastes containing heavy metals like lead or mercury, or certain pesticides. The long-term health effects are a major concern here.

Knowing these categories helps you identify which materials need special care in your facility. It's the first step to safer operations and avoiding fines. We always tell our partners, "Know your waste first!"

Why Is Getting Hazardous Waste Disposal Right So Crucial For My Operations?

Worried about the consequences of incorrect hazardous waste disposal? Fines, environmental damage, and harm to your company's name are real threats. It's a heavy burden for any business owner.

Correct hazardous waste disposal is crucial to protect health, avoid big fines, maintain a good reputation, and ensure environmental safety. It is a basic part of responsible business operations.

The impact of not handling hazardous waste correctly can be huge. We are not just talking about a small slap on the wrist. We have seen companies face serious legal actions and financial penalties. Think about the health of your employees and the nearby community. Exposure to hazardous materials can lead to severe health problems. As a business, you have a duty to protect them. I once visited a site where improper chemical storage led to a small fire – thankfully no one was hurt, but it was a wake-up call for them about the importance of these procedures.

Major Reasons for Proper Disposal:

| Reason | Explanation | Potential Impact if Ignored |

|---|---|---|

| Protect Human Health | Prevents exposure to harmful substances for employees and the public. | Illnesses, injuries, long-term health issues. |

| Environmental Protection | Stops contamination of soil, water, and air. | Damage to ecosystems, harm to wildlife, costly cleanup. |

| Legal Compliance | Follows local, national, and international regulations. | Heavy fines, legal action, business closure. |

| Company Reputation | Shows your business is responsible and cares. | Negative publicity, loss of customer trust, difficulty attracting talent. |

| Financial Savings | Reduces risks of accidents, cleanups, and fines. Can also lower disposal costs through waste minimization. | Unexpected high costs, operational disruptions. |

So, investing time and resources into getting this right is not an expense; it's an investment in the future and stability of your company. We always stress that being proactive is far better than reacting to a problem.

How Does Our Solvent Recovery System Directly Tackle Hazardous Waste Challenges?

Are you spending too much on new solvents and hazardous waste disposal fees? This eats into your profits and creates a lot of waste. There must be a better way, right?

Our Solvent Recovery System helps by cleaning used solvents on-site, turning hazardous waste into reusable assets. This reduces disposal needs, cuts costs, and supports greener operations.

Let me explain how our systems work from our experience. Many industries use solvents for cleaning, extraction, or as part of a chemical process. These solvents get dirty or mixed with other substances. Instead of throwing them away (which is costly and bad for the environment), our machines can purify them. Think of it like a mini-refinery right in your facility. For example, we helped a printing company that used a lot of cleaning solvents. Their disposal costs were very high. After installing one of our solvent recyclers, they cut their solvent purchases by over 80% and significantly reduced their hazardous waste volume. It was a game-changer for them.

How Our Systems Help:

Waste Reduction: By recycling solvents, you drastically cut down the amount of hazardous waste you need to dispose of. This is often the biggest immediate benefit.

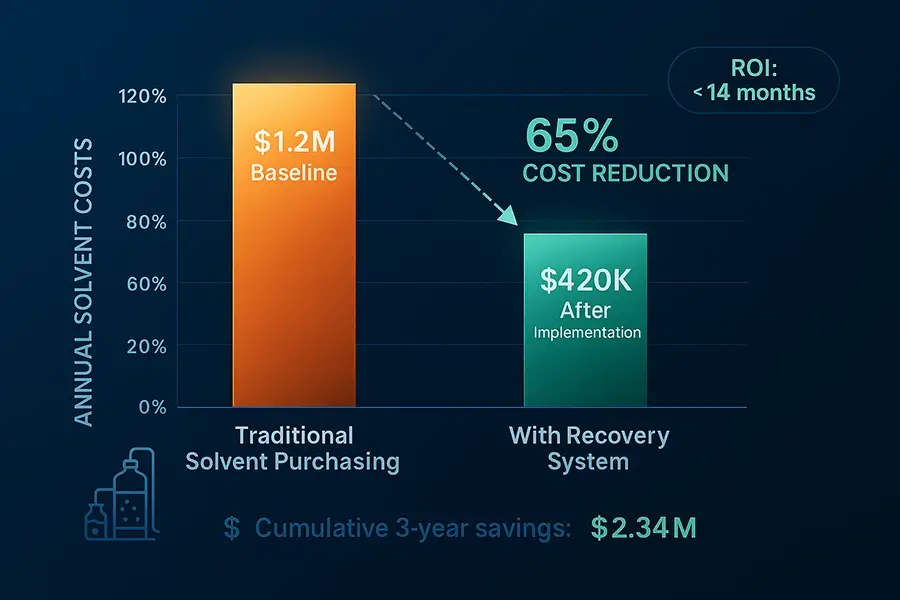

Cost Savings: You buy less new solvent and pay much less for waste disposal. The savings can be quite large over a year.

Environmental Compliance: Reducing waste helps you meet environmental regulations more easily. It also shows your commitment to sustainability.

Operational Efficiency: Having clean, recycled solvent available on-site means less downtime waiting for new supplies or waste pickups. An ethanol recovery system, for instance, can be vital for biotech or CBD extraction facilities.

Improved Safety: Less handling and transportation of hazardous waste means fewer risks for your staff and the environment.

Our equipment, like an acetone recycling machine, is designed to be easy to use and maintain. We have over 16 years of experience making these systems reliable and effective for businesses of all sizes.

What Are The Tangible Benefits Of Investing In A Solvent Recovery System For My Company?

Is investing in new equipment like a solvent recovery system really worth it? You need to see clear financial and operational gains. The initial cost can seem like a big step.

Investing in our Solvent Recovery System brings clear benefits: lower solvent costs, reduced waste disposal fees, better environmental performance, and a faster return on your investment. It is a smart business decision.

We understand that any investment needs to make business sense. Let's break down the real-world advantages we've seen our clients achieve. It's not just about being "green"; it's about improving your bottom line and operational strength. I recall talking to a manufacturing plant manager. He was skeptical at first. But after six months with our system, he showed me his spreadsheets. His company saved thousands each month on solvent purchases and disposal fees alone. That is the kind of direct impact we aim for.

Key Tangible Benefits:

| Benefit Category | Specific Advantage | How Our System Delivers |

|---|---|---|

| Financial Savings | Reduced solvent purchase costs | Recycles used solvents to near-original purity for reuse. |

| Financial Savings | Lower hazardous waste disposal fees | Significantly decreases the volume of waste requiring off-site disposal. |

| Operational Efficiency | Consistent solvent supply | On-site recycling ensures clean solvent is readily available, reducing reliance on external suppliers. |

| Environmental & Compliance | Improved environmental footprint | Minimizes waste generation and conserves resources. |

| Environmental & Compliance | Easier regulatory compliance | Helps meet hazardous waste reduction targets and regulations. |

| Return on Investment (ROI) | Quick payback period | The cumulative cost savings often lead to a return on the initial investment within a short time, sometimes less than a year. |

Beyond these, think about the enhanced safety from handling less virgin solvent and less waste. Consider the positive image for your company as a responsible, sustainable business. These might be harder to put an exact number on, but they add significant value. We've been exporting these solutions globally for over 16 years, and the feedback consistently highlights these diverse benefits.

Conclusion

Improving hazardous waste disposal is vital. Our Solvent Recovery Systems offer a practical, cost-effective solution to reduce waste, save money, and protect our environment. Let's work together for a cleaner future.