Ethanol Recycling: How It Works and Why It Matters

Discover how sustainable practices in ethanol recovery can transform your industrial operations while reducing environmental impact and costs.

What Is Ethanol Recycling?

Ethanol recycling involves recovering and purifying used ethanol from industrial or laboratory processes for safe, efficient reuse. As one of the most widely used solvents across pharmaceutical, cosmetic, and chemical industries, ethanol offers significant recycling potential. Instead of disposing of spent ethanol, recycling enables industries to reclaim valuable resources.

This circular approach reduces both environmental impact and operational expenses. To properly implement this environmentally responsible approach, companies need to understand solvent recovery fundamentals and waste disposal protocols.

Answer: Improper disposal violates environmental regulations and contributes to pollution. Recycling prevents hazardous waste while saving material costs. According to EPA, solvent recovery reduces hazardous waste generation by up to 70%.

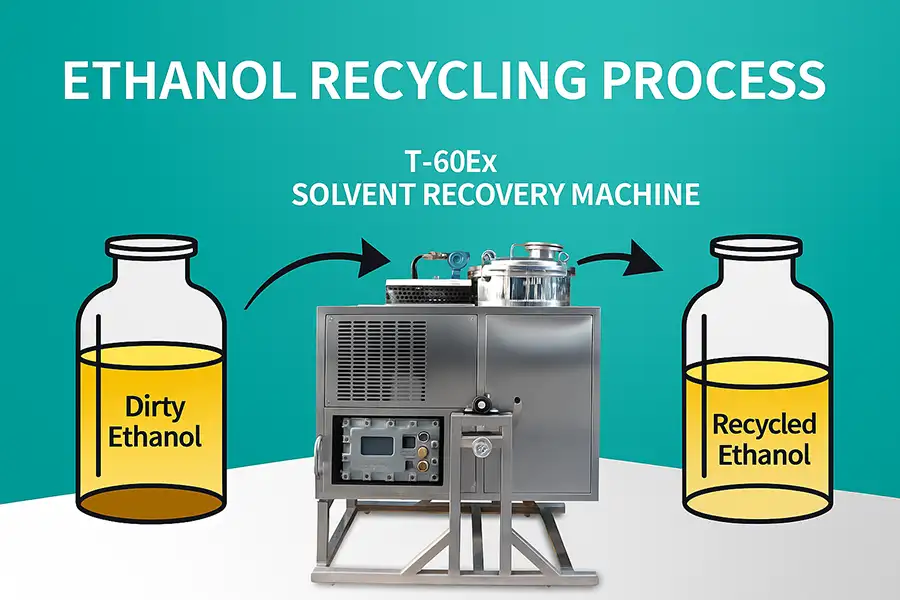

How Ethanol Recycling Works

The process relies on distillation - separating ethanol from impurities using boiling point differences. Industrial solvent recycling machines heat waste solvents until ethanol vaporizes. Vapors are then condensed back into pure liquid form, leaving contaminants behind.

Heating

Precise temperature control separates ethanol from contaminants

Vaporization

Ethanol converts to vapor form at specific boiling point

Condensation

Pure ethanol vapors are condensed back into liquid form

Modern solvent recovery systems achieve purity levels exceeding 99%, suitable for sensitive applications. These systems are compact, automated, and energy-efficient, helping industries meet sustainability goals without compromising production quality.

Industrial Applications of Ethanol Recycling

Ethanol recycling has valuable applications in:

Pharmaceutical manufacturing for cleaning and synthesis processes

Cosmetics production for formulations and extraction

Paint and coatings industries as thinner or solvent

Laboratories for sample preparation and equipment cleaning

Biofuel production as a reusable process solvent

Answer: Recycling minimizes waste, reduces carbon emissions, and conserves resources. International Energy Agency studies report solvent recovery cuts energy consumption by up to 40% compared to new solvent production.

The Role of Solvent Recycling Machines

Specialized solvent recycling systems form the core of ethanol recovery operations. These units integrate precision heating, condensation, and filtration technologies to purify solvents efficiently. System capacities range from small laboratory units to industrial-scale machines processing hundreds of liters per hour.

50-80%

Solvent Purchase Reduction

70%

Waste Disposal Reduction

40%

Energy Efficiency Gain

According to European Chemical Industry Council studies, solvent recycling technologies can reduce solvent purchase costs by 50–80%, offering substantial financial incentives for adopting ethanol recycling solutions.

Safety and Environmental Considerations

Industrial ethanol recycling requires careful safety planning. Key considerations include:

Flammability risks requiring explosion-proof equipment

Ventilation requirements for vapor management

Proper residue disposal for distillation by-products

Regulatory compliance for solvent handling and storage

For operations handling multiple solvents, integrated recovery solutions efficiently process complex mixtures. Learn more in our technical guide: How Solvent Recovery Systems Work.

Answer: Compact solvent recyclers are available for laboratories and small facilities. These units are easy to operate with minimal maintenance requirements. Our guide on solvent recycler machines provides selection criteria.

Economic Benefits of Ethanol Recycling

Implemented correctly, ethanol recycling delivers significant monetary advantages:

| Financial Benefit | Savings Range | Operational Impact |

|---|---|---|

| Reduced solvent purchase | 50–80% | Lower material costs |

| Waste disposal reduction | Up to 70% | Reduced compliance costs |

| Energy efficiency gains | Up to 40% | Lower utility expenses |

| Tax incentives | Varies by region | Improved cashflow |

Interested in Specific Cost Savings?

Calculate your potential ROI with our solvent recovery calculator for precise savings projections.

Estimate SavingsConclusion

Ethanol recycling represents more than technical innovation—it's a strategic implementation of circular economy principles. Modern solvent recovery systems help industries reduce costs by 50-80%, minimize environmental compliance risks, and enhance sustainability metrics.

For additional information on solvent recovery technologies, explore our educational resources:Understanding Solvent Recovery and Solvent Waste Management.

Key Benefits

Up to 80% reduction in solvent purchase costs

70% reduction in hazardous waste generation

ROI achieved in 6-24 months for most systems

Simplified regulatory compliance

Improved sustainability credentials

Industry Resources

Get Expert Consultation

Schedule a free consultation with our solvent recovery engineers

Request Consultation