Solvent Waste Recycling Services: A Complete Guide

Discover how modern solvent recycling systems reduce waste, save money, and support sustainability

What Are Solvent Waste Recycling Services?

Solvent waste recycling services refer to the professional processes and equipment used to recover, purify, and reuse solvents that have been contaminated during industrial or laboratory operations. Instead of disposing of used solvents, these services reclaim them, reducing both environmental impact and operational costs.

In industries like automotive, pharmaceuticals, printing, and manufacturing, solvents are vital for cleaning, dissolving, and processing various materials. However, after use, they often contain impurities, making them hazardous waste if not managed properly.

Improper disposal of solvent waste can lead to soil and water contamination, air pollution, and legal penalties. According to the U.S. Environmental Protection Agency (EPA), hazardous solvent waste contributes significantly to industrial pollution each year. This makes solvent waste recycling an essential part of sustainable waste management.

Recycle

Transform waste solvents into valuable reusable materials through efficient recycling processes.

Reduce Impact

Minimize environmental footprint by preventing solvent contamination in landfills.

Save Costs

Reduce operational costs by reusing solvents instead of purchasing new chemicals.

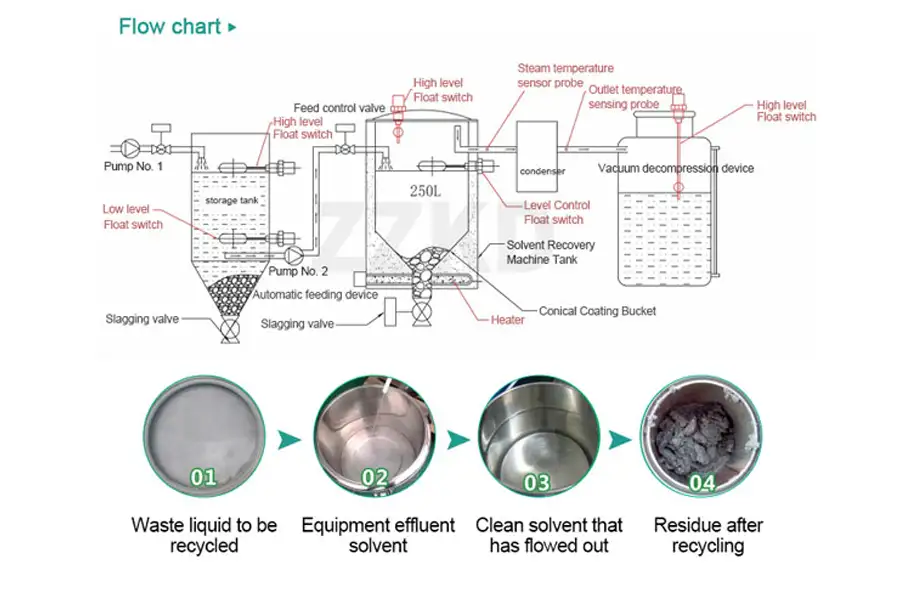

How Do Solvent Recycling Machines Work?

Solvent recycling machines, sometimes referred to as solvent recycler machines, use distillation or filtration to separate contaminants from used solvents. The process typically includes heating the waste solvent until it evaporates, then condensing the pure vapor back into liquid form. The result is a clean, reusable solvent and a small amount of concentrated residue.

This method is both cost-effective and environmentally friendly. A single recycling cycle can recover up to 95% of usable solvent, drastically reducing the need for new solvent purchases.

Not at all. Modern solvent recycling systems are designed for ease of use. Many units, such as the ones described in our solvent recycling system guide, come with automated temperature control, safety sensors, and digital interfaces. Operators simply load the solvent waste, set the parameters, and the machine handles the rest.

Why Businesses Are Turning to Solvent Waste Recycling Services

The shift toward solvent waste recycling is driven by both environmental responsibility and economic logic. Recycling reduces the cost of purchasing new solvents and minimizes hazardous waste disposal fees. Additionally, it aligns with growing corporate sustainability goals.

According to a report by the World Economic Forum, companies that integrate circular economy principles—like solvent recycling—can reduce material costs by up to 30%. This makes investing in solvent recovery systems an intelligent business decision.

Furthermore, the global solvent recycling market is projected to grow steadily as industries seek greener production methods. Many organizations now include solvent recycling in their Environmental, Social, and Governance (ESG) initiatives.

Depending on the type of solvent and the recycling system used, recovery rates typically range from 80% to 95%. For example, acetone or isopropyl alcohol can be efficiently reclaimed using our specialized acetone recycling machine, reducing waste volumes dramatically.

Reduction in disposal costs

ROI on recycling equipment

Scientific and Technological Advancements

Modern solvent recycling services are becoming smarter. Artificial intelligence (AI) and IoT technologies are being integrated to monitor solvent purity, optimize energy use, and predict maintenance needs. According to research from the Massachusetts Institute of Technology (MIT), AI is expected to automate up to 30% of industrial operations by 2030, including process optimization in solvent recovery systems.

This means future solvent recyclers will not only recover solvents efficiently but also make data-driven decisions to enhance sustainability.

Smart Solvent Recovery Systems

Advanced AI-powered systems automatically optimize solvent recovery processes

Environmental and Legal Benefits

Solvent recycling contributes to reducing greenhouse gas emissions by lowering the demand for virgin solvent production. It also helps companies comply with environmental regulations such as the Resource Conservation and Recovery Act (RCRA) in the U.S., which governs hazardous waste management.

For industries dealing with chemicals like paint thinners, methanol, or nitric acid, proper disposal and recycling are crucial. For example, proper disposal of isopropyl alcohol ensures safety and compliance, while recycling reduces the need for new chemical purchases.

Reduces hazardous waste by 90%+ and prevents ecosystem contamination by keeping solvent waste away from landfills and waterways.

For responsible disposal of other chemicals, see our guides on methanol disposal and nitric acid disposal.

Helps companies comply with EPA standards (RCRA), OSHA requirements, and local regulations, avoiding potential fines up to $75,000 per violation.

Our systems ensure you meet all requirements for solvent waste management.

Choosing the Right Solvent Waste Recycling Service

Selecting a reliable service provider or investing in the right solvent recycling equipment depends on factors such as solvent type, waste volume, and industry standards. A good provider will offer customized solutions, technical support, and compliance documentation.

For industrial facilities, on-site solvent recycling systems are often the most efficient option. They allow immediate recovery and reuse, minimizing downtime and transportation costs.

Solvent Type: Different solvents require different recycling methods (acetone, IPA, methanol, etc.)

Daily Volume: Capacity requirements (liters/gallons per day)

Purity Standards: Required output quality for reuse in your processes

Energy Efficiency: Energy consumption and operational costs

Compliance Needs: Industry-specific regulatory considerations

Conclusion: The Future of Solvent Waste Recycling

Solvent waste recycling services are no longer just an environmental choice—they are a strategic business advantage. By reclaiming solvents efficiently, companies can save money, meet environmental regulations, and demonstrate corporate responsibility.

As technology continues to advance, solvent recyclers will become even more efficient, automated, and sustainable. The combination of smart systems and eco-conscious practices is paving the way for a cleaner industrial future.

For more information on how solvent recycling systems work, visit our detailed guide on how a solvent recovery system works or learn about solvent recovery fundamentals.